Verification of Drive Systems

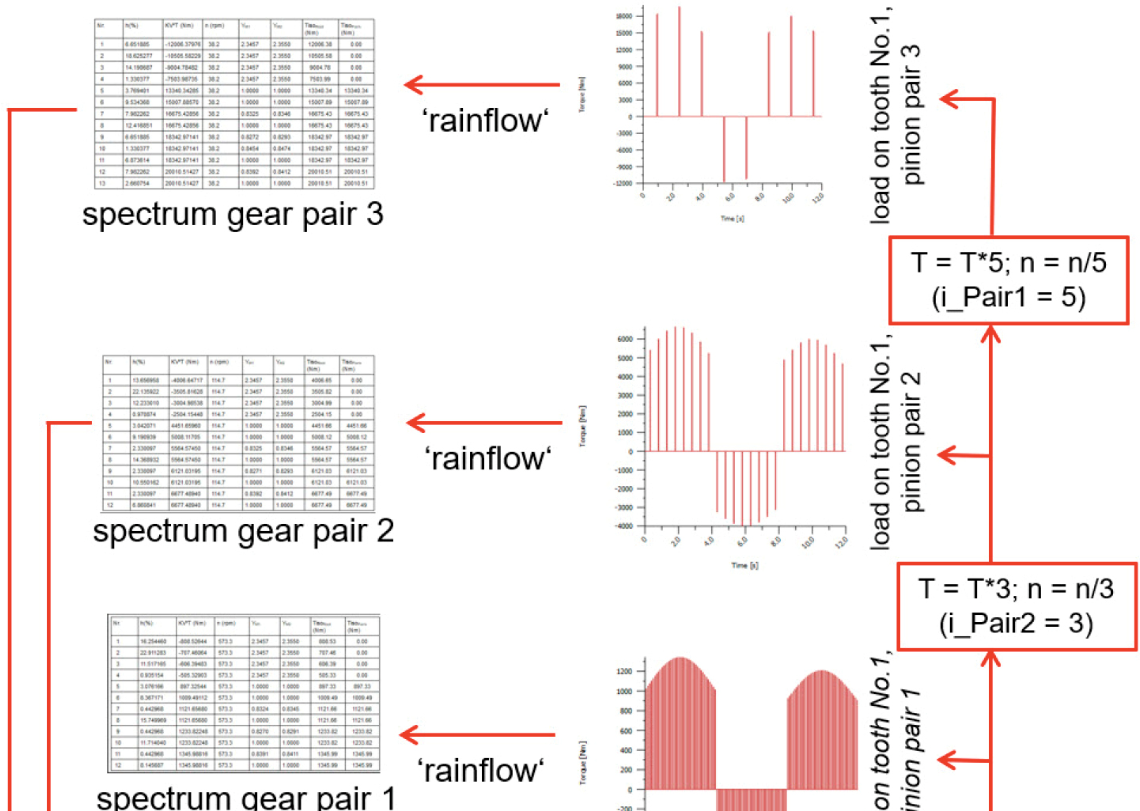

Today the analysis of drive trains is performed with appropriate software such as KISSdesign (Ref. 12) which permits modeling the complete drive with all the main elements. Normally the time series is measured at the input or the output coupling. The handling of a time series for a drive train can be made in two different ways. The “simple variant,” using the same load spectrum for each element of the drive The “general variant,” generating individual load spectrums for different elements (such as gears, shafts, bearings) and for each stage of the drive Use of Time Series for Drive Systems with the Simple Variant A load spectrum of type A (Table 2) must be defined at the input or output of the system, at the location where the time series was measured. This load spectrum is then used across the drive system for all gears, shafts, and bearings. For this scope, it is preferred that torque and speed in the load spectrum are given as factors to be multiplied by the nominal values (see Figure 6). The drive train software will calculate the nominal speed/torque of every single element, and the same load spectrum, if defined with factors, can be used everywhere. The simple variant can be used with any drive system software permitting the use of load spectrums without any further adjustment. If the torque and speed of the time series are always positive, or if some infrequent negative values can be neglected, then this method is preferred. The results for gears and bearings will be perfect, load spectrum of type A is used. For an accurate shaft verification, always load spectrum of type B should be used, otherwise, the shaft strength will not be accurate. Often shaft strength is not critical. The use of load spectrum type A—and assuming the torsion and shear as pulsating for shaft verification—will produce conservative results (on the safe side). So, if the results are satisfying, there is no need for a more complex analysis.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Fatigue Strength Verification

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.