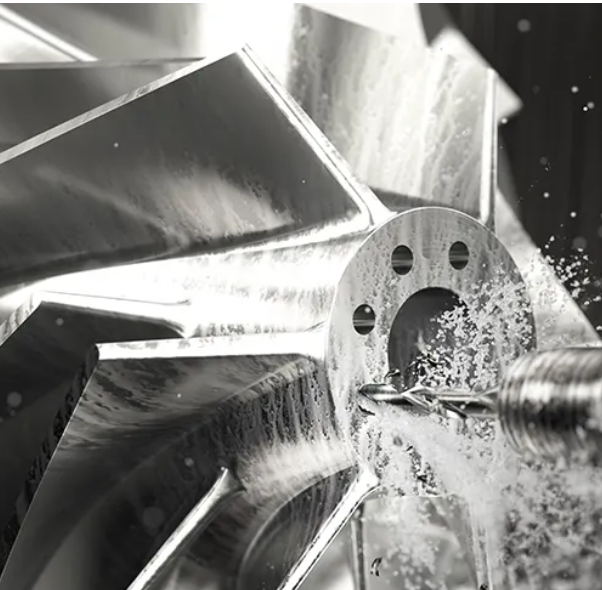

A drill to trust for nickel-based HRSA components with -SD geometry for secure short hole drilling

Global metal cutting leader Sandvik Coromant introduced a new solid carbide drill optimized for drilling in nickel-based heat-resistant super alloy (HRSA) materials, with a standard drilling depth capability of up to 8 × D. The new CoroDrill 860 with -SD geometry offers a consistent and predictable tool life with high hole integrity, which is of the utmost importance in industries with extremely high demands and processes in place to safeguard quality, such as the aerospace industry. Current strategies for drilling nickel-alloy aircraft engine parts, where process security is paramount, cannot meet high demands from the industry and do not offer a maximum tool life. That's where the new CoroDrill 860 with -SD geometry, which is purpose-designed for superior machining of nickel alloys, comes in. “The CoroDrill 860 with -SD geometry is a reliable drill that guarantees the highest performance and process security for HRSA materials,” says Robert Smith, offer manager for hole making and composites at Sandvik Coromant. There are several key features that contribute to the high performance for HRSA materials. First is the unique grade — S2BM — which combines a fine-grained cemented carbide substrate, a multilayer PVD coating and a post-treatment, delivering maximum tool life. Additionally, geometry with optimized clearance angles and highly controlled edge preparation, flute shape, corner chamfer and double margin result in a drill that guarantees the highest performance and process security. Extensive design development and comprehensive product tests in multiple HRSA materials have shown that the CoroDrill 860 with -SD geometry performs consistently in 3, 5 and 8 × D applications, offering excellent machining stability and process security. This makes process planning and cost calculations more reliable when predicting tool life and conducting cost-per-part analysis. “Customers can be confident that the CoroDrill 860 with -SD geometry is a reliable drill that guarantees the highest performance and process security, delivering the longest possible tool life to reduce the cost per hole and component,” says Smith. “The CoroDrill 860 with -SD geometry is the drill to trust for high-value components.”

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.