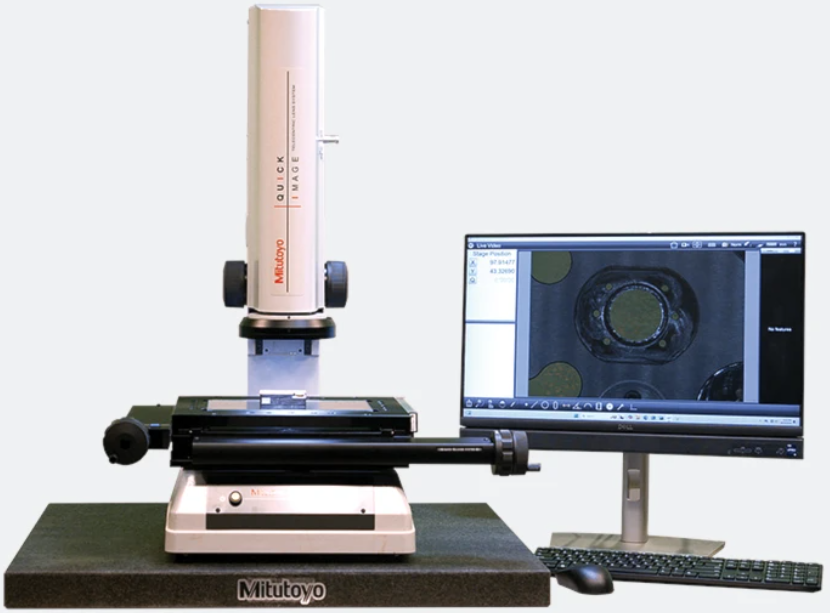

MITUTOYO'S METLOGIX M3 WITH THE MITUTOYO QUICK IMAGE VISION SYSTEM

Mitutoyo America Corporation, a leader in precision measuring instruments, is excited to announce the integration of the powerful Metlogix M3 software into the Mitutoyo Quick Image (QI) 2D Vision Measuring System. This latest enhancement promises to elevate the precision and efficiency of non-contact measurements, further solidifying Mitutoyo’s commitment to providing innovative technology solutions to meet modern quality control needs.

Unmatched Efficiency and Ease of Use

The integration of Metlogix M3 software transforms the Quick Image system, known for its superior accuracy and ease of use, into an even more robust tool for non-contact measurements. The M3 software introduces a highly intuitive, icon-driven interface designed for simplicity and speed.

Features:

Pattern-Based Measurements: The M3 software provides innovative pattern-based tools that simplify the measurement process, making it easy to measure multiple points in a single action. This dramatically reduces setup time and increases productivity.

Advanced Video Probes: The software’s advanced video edge detection tools, such as EyeMeasure and MeasureLogic, enable fast, accurate edge and feature capture. The VTouch probe brings unprecedented functionality by allowing video-based touch probing for quick acquisition of individual points.

Field of View Measurement: Metlogix’s powerful Field of View (FOV) functionality automates part measurements by simply placing multiple parts in the camera’s view. The system detects, measures, and displays results without the need for operator intervention, streamlining the inspection process.

SuperImage Stitching: For larger workpieces up to 400mm, the Quick Image system utilizes an ultra-long 90mm working distance to capture and stitch multiple frames into a single image with Metlogix’s SuperImage feature. This function enhances accuracy and clarity over larger areas while allowing flexible, soft fixture setups for repeated measurements.

Versatility and scalability

With the enhanced capabilities of the M3 software, the Quick Image system can support a wide range of workpiece sizes, measuring up to 400mm with its stage stitching function. This ensures that manufacturers can measure larger components with precision and efficiency.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.