WEVO'S SILICONE GAP FILLER

With WEVOSIL 26040 FL, Wevo is expanding its portfolio of thermal interface materials (TIMs) with a specially optimized silicone gap filler. The material features high thermal conductivity of 4W/m*K, a very low bond line thickness (<70 µm) and enhanced sedimentation stability. In addition, the dosing profile has been sharpened to secure an efficient production process. So, the new thermally conductive material offers a process- and application-optimized solution for the thermal management of numerous electrical and electronic applications, from power electronics to battery technologies.

Whether it’s high dosage volumes, reliable heat dissipation for large surfaces or mechanically demanding thermal joints that are needed – the new silicone gap filler from Wevo is a state-of-the-art solution for numerous requirements in contemporary electronics and electrical engineering. With a thermal conductivity of 4W/m*K, measured according to ASTM D5470-2017, the product ensures efficient heat dissipation and bridges small gaps thanks to the specially developed filler combination and the resulting very low bond line thickness of < 70µm. Furthermore, material properties such as reactivity can be customized to individual needs.

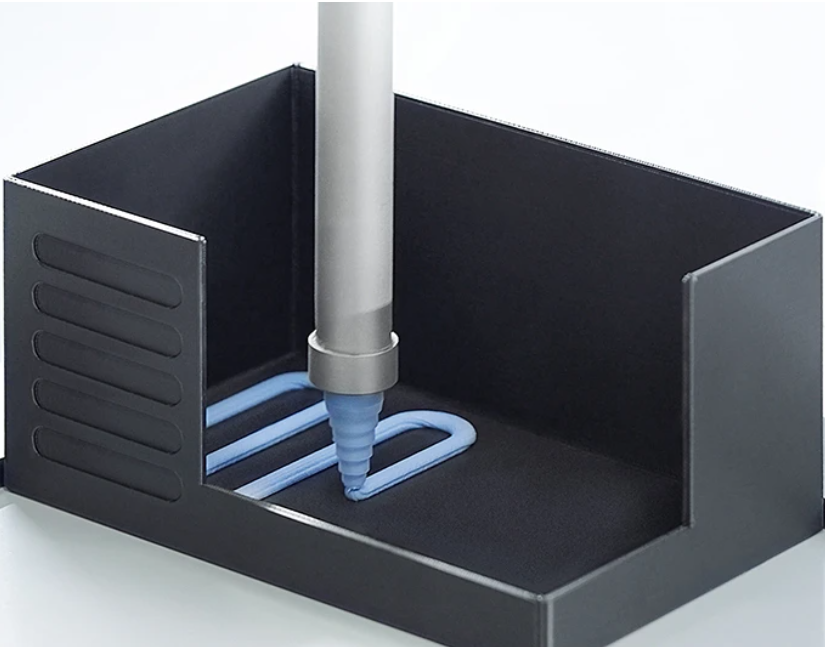

Thermal interface material with optimized dosing profile

At the same time, the material has been formulated to be very resistant to sedimentation, allowing it to be stored, used and transported over long distances over a period of at least three months without having to be re-homogenized. Moreover, the optimized dosing properties permit simple and efficient handling, high dispensing speeds and fine dosing patterns. Compared to thermally conductive pads, this ensures significantly greater precision and flexibility in production, which is particularly advantageous when manufacturing large unit volumes.

In addition, the newly developed silicone gap filler offers high temperature resistance of up to 200 °C, flame-retardant properties in accordance with UL 94 V-0 (as of a thickness of just 2 mm) and good mechanical properties, including elongation at break of more than 30%. When cured, WEVOSIL 26040 FL meets the requirements of the PV 3040 test specification for low-volatile emissions in the automotive industry and is therefore suitable for a wide range of applications.

With its state-of-the-art, customizable properties, Wevo’s new thermally conductive material helps ensure the safe operation and longevity of innovative electronic and electrical components.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next ABB introduces new food-safe motor design to improve reliability and safety

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.