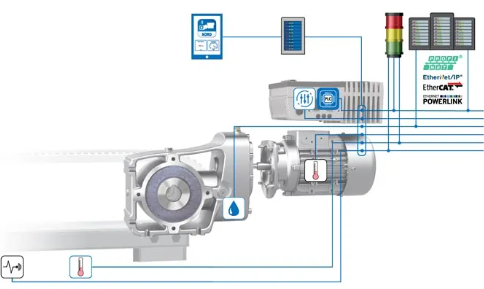

Condition Monitoring for Predictive Maintenance from Nord Drivesystems

With condition monitoring for predictive maintenance, drive and status data are recorded at regular intervals or continuously to optimize the operational safety and efficiency of systems. The results derived from data analysis enable machines to be proactively maintained and avoid unplanned downtimes. This status-based maintenance approach prolongs the service life of components and machines, increases system availability, and reduces service and material costs. Condition monitoring can even determine the optimal time to change oil, ensuring systems are always operating at their highest capacity.

Nord Drivesystems condition monitoring for predictive maintenance solution. Nordac Pro variable frequency drives from Nord Drivesystems enable dynamic control of gear units, provide precise control, and can be easily configured to meet application needs. They are characterized by their compact, space-saving design, advanced control characteristics, and uniform parameterization. Their versatile functionality is available in five frame sizes with powers ranging from 0.33–30 HP with optional modules to extend features. Ease of operation is achieved via several interfaces including an integrated multi-protocol ethernet interface for connectivity to ethernet-based control systems, a USB interface that enables parameterization even when the main power is disconnected, a Bluetooth interface, and an SD memory card slot for storage and transfer of parameters, firmware, and operating data. Integrated programable logic controller (PLC) functionality and Posicon positioning control provide further intelligent control optimized for specific system needs. Functional safety is also implemented with safe torque off (STO) and safe stop 1 (SS1) options for safe shutdown to prevent hazards to people and damage to system components. Nordac Pro variable frequency drives (VFDs) are a part of Nord’s modular product system and are compatible with both synchronous and asynchronous motors. Sensorless current vector control enables high starting torques and precise control of motor speeds. The drives also feature motor brake management, lifting gear functionality, a brake chopper, and extensive monitoring functions. Thanks to their high level of performance, safety, and versatility, Nordac Pro VFDs are used in a wide range of industries such as airport baggage handling, intralogistics, bulk material handling, packaging, and more.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Safety Measures in the Danger Zone

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.