CREAFORM METROLOGY SUITE EXPANDS CAPACITIES

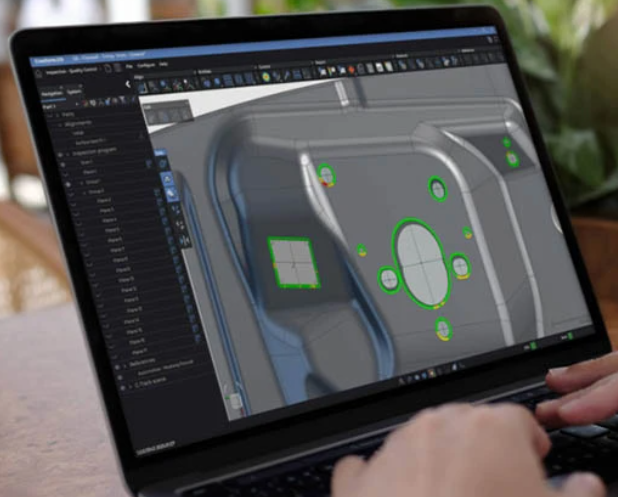

Creaform, a business of AMETEK Inc. and global provider of automated and portable 3D measurement solutions, released the new Sheet Metal add-on as part of the recently released Creaform Metrology Suite. Designed to address industry specific needs, it tackles the many challenges of sheet metal inspection in the metalworking, automotive, and aerospace industries. Providing measurements of sheet metal parts with never-before-seen accuracy and repeatability for 3D laser scanners, this software solution gives Quality Control (QC) and Quality Assurance (QA) professionals a higher confidence level in their 3D scan data, while empowering manufacturers to fully trust their inspection reports. Measuring thin sheet metal parts using 3D scanners used to be highly dependent on the users and the resolution settings. Now, however, the results generated by the new Sheet Metal add-on are user independent. It quickly provides accurate and repeatable information on all sheet metal features, such as edges, holes, slots, rectangles, and trimmed edges. This specialized add-on provides the most flexible, complete, and simple measurement method, working in perfect synergy with the HandySCAN 3D|BLACK Series and all handheld MetraSCAN BLACK+ scanners. New features and benefits include: Accuracy and repeatability: Powered by advanced image algorithms, the Sheet Metal add-on enables accurate and repeatable measurements that are independent from operator skills. Simplicity & flexibility: The measurement process is straightforward, requiring no additional hardware accessories and eliminating the need to navigate complex or overwhelming software parameters. Speed: The measurement process of the new Sheet Metal add-on is up to 5 times faster than CMM processes. Intuitive interface: Includes a new visualization tool that allows users to validate that their data acquisition is ready for inspection before proceeding, saving time by removing unnecessary steps. Value for money: It offers a cost-effective alternative to expensive and time-consuming CMM solutions, ensuring a quick return on investment.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next OES’ 30MM VERTICAL LIFT STAGE

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.