Research Team Led by Professor Rencheng Zu at Tianjin University Proposes Novel Method for Characterizing Friction Characteristics of Rolling Bearings

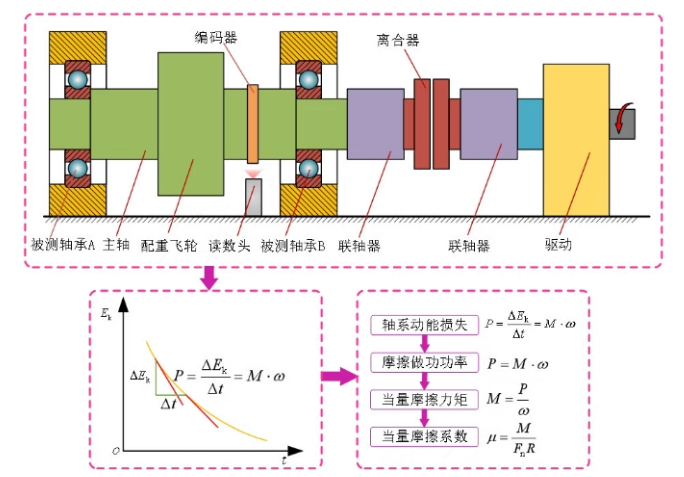

Rolling bearings are key basic components for satellite momentum wheels, gyroscopes and other precision aerospace instruments, and friction performance is a comprehensive indicator to measure their quality. In view of the problems that the friction torque used to characterize the friction performance of bearings is highly dependent on working conditions, has large discreteness and poor stability, the team led by Professor Ren Chengzu of Tianjin University proposed a method for measuring the equivalent friction coefficient of rolling bearings based on the kinetic energy theorem. The measurement principle is shown in Figure 1. By measuring the equivalent friction coefficient under high-speed free deceleration conditions, the dynamic attenuation law of the tribological performance of rolling bearings with speed is revealed, and the complex friction behavior of rolling bearings is converted into changes in kinetic energy dissipation rate to achieve dynamic quantitative characterization. This study breaks through the steady-state measurement limitations of the traditional torque balance method and realizes a principled leap from static torque balance to continuous kinetic energy dissipation in the dimension of friction performance evaluation. An equivalent virtual sliding bearing model that takes into account the internal friction behavior of rolling bearings is established, and a dimensionless equivalent friction coefficient that characterizes the comprehensive friction characteristics of rolling bearings is defined, providing a new way to evaluate the friction performance of different types of bearings. Based on the principle of free deceleration of bearings, a friction coefficient measurement platform for rolling bearing friction equivalent is established, which realizes the measurement of the friction performance of the measured bearing under continuous speed conditions. High-precision grating speed sensors are used to replace traditional torque sensors, which solves the contradiction of "high precision means small range, and large range means low precision" of torque sensors in traditional bearing friction measurement equipment, and improves the measurement accuracy of rolling bearing friction performance by 1-2 orders of magnitude.

The implementation of the measurement technology in this study will greatly improve the measurement accuracy of the tribological performance of precision rolling bearings, and lay a technical foundation for effectively improving the service reliability and extreme working conditions applicability of rolling bearings in the aerospace field (such as satellites, inertial navigation systems, etc.), promoting the further upgrading of the rolling bearing industry, and helping my country achieve the strategic goal of independent control of key basic components.

The relevant results of this study have been published in the internationally renowned journals "Friction" and "Measurement". Among them, "Measurement of the equivalent friction coefficients of ball bearings based on the variations in kinetic energy" was selected as the cover of "Friction" (Figure 2). Dr. Wu Panlong is the first author, and Associate Professor He Chunlei and Professor Ren Chengzu are the corresponding authors. The relevant research is supported by the National Key R&D Program (2018YFB2000401) and the National Natural Science Foundation of China (51935008, 52175430). The new method for characterizing the tribology of rolling bearings has been authorized with Japanese patents and Chinese invention patents. The first author of this article, Wu Panlong, is currently employed at the Institute of Basic Parts and Tribology, Zhengzhou Research Institute, Harbin Institute of Technology, and is mainly engaged in the research of bearing tribological performance and stability.

Some recent academic papers published by the research group in the field of bearings:

1. Wu P, He C*, Ren Z*, et al. Measurement of the equivalent friction coefficients of ball bearings based on the variations in kinetic energy. Friction, 2025, 13(5): 9440947. https://doi.org/10.26599/FRICT.2025.9440947 (Back cover)

2. Wu P, He C*, Chen G, et al. Determination of the equivalent friction coefficient of rolling bearings using the kinetic energy dissipation. Measurement, 2025, 244: 116533.

3. Wu P, He C*, Chang Z, et al. Theoretical calculation models and measurement of friction torque for rolling bearings: state of the art. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2022, 44(9): 435.

4. Zhang J, He C*, Chen G, et al. Roundness variation of tapered rollers in double-disc straight groove lapping process. Journal of Manufacturing Processes, 2024, 126: 413-428.

5. Geng K, He C*, Wang S*, et al. The rotation stability of the tapered rollers in a novel ring-type lapping process. Precision Engineering, 2024, 88: 927-942.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Announcement on LYC Rights Protection Case

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.