A New Process for Differential Gear Manufacturing

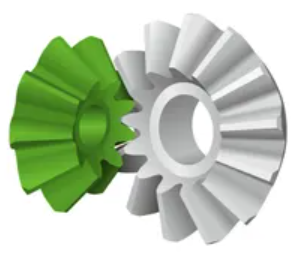

Enhancing strength, efficiency and quiet performance for electric vehicles The manufacturing of differential gears went away from the Revacycle broaching process to forging more than 30 years ago. Today, where electric vehicles create a peak torque which are a multiple higher than in vehicles with internal combustion engines, the strength and the Noise Vibration Harshness (NVH) advantages of cut differential gears are revisited. The newly developed Coniflex Pro straight bevel gears combine several new features which make them stronger and quieter than past straight bevel gears and far superior to the forged version. The basic geometry of Coniflex Pro was developed especially for modern Phoenix free-form CNC machines and takes advantage of the “unlimited” geometric freedoms and the possibility of higher order, nonlinear kinematics. First field applications have proven that Coniflex Pro differentials have 30 percent lower root bending stress and 40 percent lower surface stress as forged differential gears. Many electric all-wheel drive vehicle applications with a front axle disconnect feature create high relative motions in the differential of the disconnected axle, which makes the transmission very noisy. Coniflex Pro gears have the lowest transmission error of any ever-produced straight bevel gear. While transmission errors of 50 microradians (µrad) or less are typical for Coniflex Pro, conventionally cut or forged straight bevel gears show between 300 and 2,000 µrad. Coniflex Pro differentials are therefore exceptionally quiet, even in case of high relative motions in disconnect axles.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next RENK Group AG Completes Acquisition of Cincinnati Gearing Systems Inc.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.