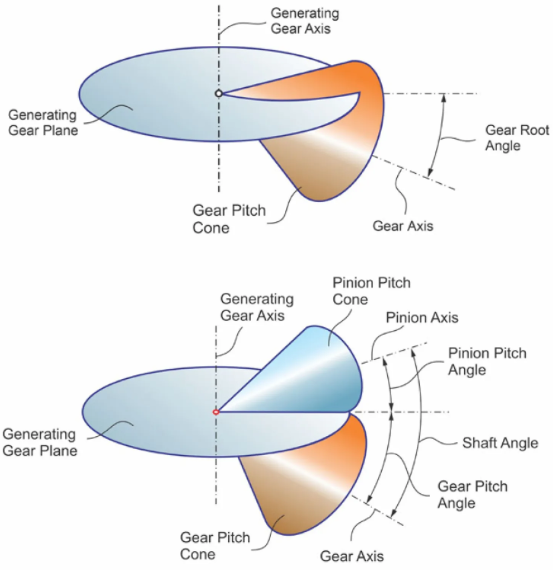

Generating on the Pitch Cone

All the older straight bevel gears are generated by rolling on the root cone, rather than on the pitch cone. Figure 1 shows to the left the traditional orientation between the generating plane and the pitch cone of a gear. This orientation violates the kinematic coupling condition between gear, generating plane and pinion. Both mating Coniflex Pro members roll with their pitch cones on the common generating gear plane as shown to the right in Figure 1. This was not possible in the past because the tip circle of the cutting tool had to be adjusted to the root angle of the tapered depth teeth of the gears and due to the mechanical restrictions of older machines, the generating gear rotation was automatically orthogonal to the root line of the cut gear. Thus, the gears were generated on the root cone rather than on the pitch cone.

Free-form Phoenix machines do not have the traditional mechanical restrictions. Therefore, the choice of adjusting the cutter tip circle tangential to the root line of the cut pinion and gear and yet performing a roll motion around a generating gear axis perpendicular to the gear’s pitch cone has become possible with Phoenix machines. The result is a perfectly conjugate interaction between pinion and gear, like shown in the contact analysis in Figure 2. The ease-off topography is zero and the tooth contact extends over the entire working area. The motion transmission error has a slight numerically caused variation but is practically zero. To prepare a gear set for manufacturing tolerances and deflections under load, length crowning can be created with a dished cutter as shown in Figure 3 and profile crowning can be created with a second order ratio of roll modification.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.