Coniflex Pro is a new development of straight bevel gears

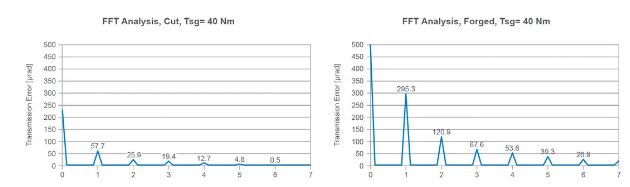

Coniflex Pro is a new development of straight bevel gears which, in contrast to the original Coniflex process, takes advantage of the geometric and kinematic freedoms available in Phoenix free-form machines. The advantages of a conjugate base geometry and the free control of length and profile crowning with the possibility of a kinematic tip relief in connection with positive profile shifts in pinion and gear have been compelling facts for manufacturers of differential gears for electric vehicles. The number of Coniflex Pro EV differential gear designs is constantly increasing. Coniflex Pro differential gear sets can be designed and optimized in the Gleason GEMS software system. The tools used are Coniflex Plus stick blade cutters. Digital flank form data including correction matrixes can be transferred via network to coordinate measuring machines and a closed correction loop between measurement and manufacturing machine can be established. Also, the machine summaries for blade grinding, cutting, and grinding are generated in GEMS and can be transferred to the manufacturing machines via the network. Coniflex Pro differential gears can be ground after heat treatment. Standard differentials might, in extreme cases, see a maximum of 400 rpm relative speed between side gear and planet. For some EV drive concepts, the maximal relative differential speed is six times higher, which calls for a hard finishing operation after the heat treatment. GEMS also generates grinding summaries and grinding wheel geometry and design data. Cutter head and grinding wheel consolidation between different gear designs is easily possible because the profiles of blades and grinding wheels are simply straight. The major advantage of Coniflex Pro is the power density, which can be twice that of conventional differentials. The quiet rolling is a welcome additional advantage. Both the high power density and low NVH properties make the change from forged differential gears to Coniflex Pro very interesting, especially for modern electric vehicles.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.