How is lubrication technology evolving in manufacturing today?

Lubrication technology is evolving largely through dispensing methods. The automatic systems have changed from basic self-contained electro-chemical or electro-mechanical systems to more advanced versions featuring multiple outlets, multiple pumps and with PLC integration. What do your lubrication experts recommend between selecting greases or oils? What are the advantages/disadvantages of both options? We recommend NLGI 0 (very soft) or 00 (semi-fluid) grease. This consistency range works for many open gearing applications because of the balance between flowing freely through any accessory components for distribution while also staying in place once applied. Oils are not ideal for open gearing because they are more likely to flow resulting in more mess and positionally not enough surface coverage. Give our readers some insight into single point and multi point lubrication strategies and discuss functions, applications and benefits for each system.

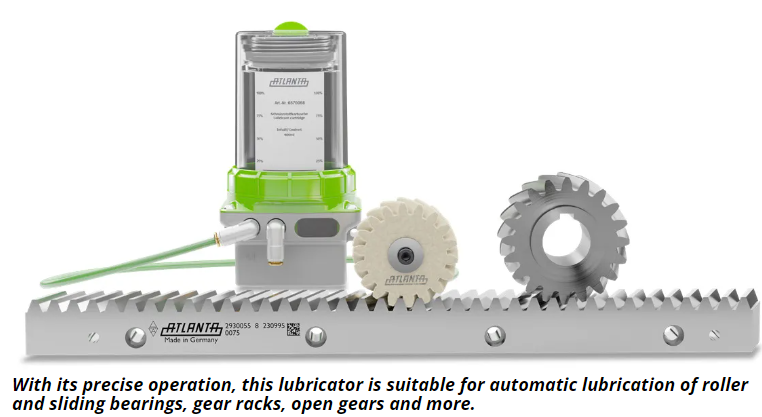

Every system has unique lubrication challenges so having options to choose from single point or multi-point lubrication is critical. Single point systems are perfect for when a simple solution is required. They come in a wide range of sizes and generally they are more compact compared to multiple-point solutions. Lubrication dosages are straightforward to calculate and adjust when you are dealing with only a single point. This is normally done through DIP switches or an LED display. Power options using batteries or eternal power supplies are available depending on what the system design allows. Single point systems can be electro-chemical or electro-mechanically driven Multi point systems are ideal for larger systems. They can be used for multiple lubrication points of the same type or different types. Combinations of open gears, chains, bearings, spindles, or linear guides could utilize a multi-point system to reduce the lubrication reservoirs. Multiple outlets and multiple pumps are common features. This allows for variable flow rates for the different lubrication points. Multi point systems typically include more advanced features and optional PLC controls. PLC integration provides feedback on the lubrication unit like low lubrication levels, lubricating pressure, and pump errors. This feedback is valuable for identifying issues between regular maintenance. Power options using batteries or eternal power supplies are available, but most are externally powered in our experience. These systems are generally mechanically driven and operate at higher pressures compared to single point systems.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Why is a reliable lubrication system so critical to open gearing applications?

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.