Application of the Calculation Method to an Electric Car Gearbox

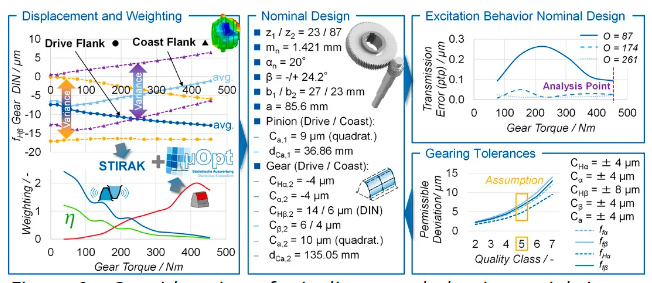

The design method presented in the section “Calculation Method for Designing the System Tolerances of a Cylindrical Gear Stage with the Integration of Manufacturing Efforts” is applied as an example to a series-like e-drive gearbox. First, general data on the application is presented. Subsequently, the results for an optimized tolerance design are compared with the reference tolerance definition in terms of excitation variance and manufacturing costs. Gearbox and Gear Data As an example, an e-drive gearbox is used (Ref. 40). It was designed to have similar characteristics as a real series gearbox in terms of geometry, material and stiffness. The first, high-speed cylindrical gear stage is considered. The helix angle deviations due to load-induced deflections at the gear shown in Figure 9, top left, are obtained, which were integrated into the FE-based tooth contact analysis in order to perform time-efficient variant calculation. The diagram shows the wide variance of the possible helix angle deviations resulting from different bearing clearances. These result from the minimum (minimum of class C2) and the maximum permissible bearing clearance (Ref. 41). This results in scattering of ΔfHβ > 10 µm, only due to the selection of the bearing clearance class and the possible manufacturing scatter. A medium tolerance was used for designing the micro-geometric nominal design. A microgeometry variation comprising n = 1,908,360 variants resulted in the micro geometry shown in the center of Figure 9 as the best compromise variant, given the weighting shown in Figure 9, bottom left, which is based on the driving profile of a WLTP test cycle (Ref. 32). To identify the best nominal design under consideration of geometric scatter, the manufacturing tolerances derived from quality class A 5 in Figure 9, bottom right were defined. They were increased with regard to the helix angle deviation due to the additional influences of other components on the deviation error of axes and inclination error of axes described above. The tolerance field design approach for the microgeometry stated by Brecher et al. was applied (Ref. 14). If the deviations assumed during the nominal microgeometry design in tooth contact change significantly due to the tolerance design of the overall system, the nominal microgeometry should be redesigned in order to ensure a suitable nominal microgeometry.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Modeling the Cost-Deviation Relationships for Geometric Features

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.