Using Steel–POM and POM–PA66 Gear Pairs Operating Under Dry Conditions

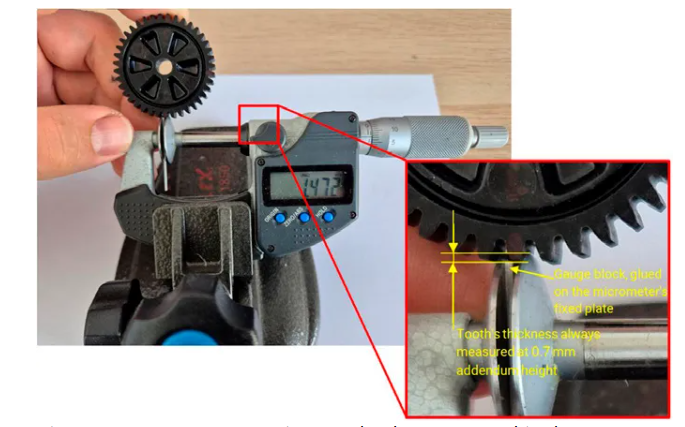

The effect of wear was investigated using Steel–POM and POM–PA66 gear pairs operating under dry conditions. Tests were carried out at a torque of 2.0 Nm, a rotational speed of 1,400 rpm, and a gear temperature of 80°C. Each gear pair was subjected to five consecutive test intervals, with 2 million load cycles per interval. An initial benchmark NVH measurement was performed on unworn gears at the start of the first interval. Subsequent wear assessments and NVH measurements were conducted after every 2 million load cycles (approximately 24 hours of operation), up to a total of 10 million load cycles. For each material combination, three independent tests were performed. Wear was quantified based on the reduction in chordal tooth thickness. To ensure measurement consistency, the chordal height specific to the gear geometry was first established. A customized Mitutoyo micrometer screw gauge equipped with round anvils was utilized for the chordal thickness measurements. The chordal addendum was fixed at 0.7 mm from the tooth tip, using a gauge block affixed to the stationary anvil of the micrometer (Figure 11), thereby standardizing the measurement location across all test intervals. To eliminate variability due to gear positioning, all intermediate wear measurements were conducted with the gears mounted on the test bench, preserving a constant center distance throughout the testing campaign. For each gear, four representative teeth, uniformly distributed along the circumference, were marked and used for repeated measurements. Final wear measurements were performed after the gears were removed from the test rig. Figure 12 illustrates the correlation between progressive wear and NVH behavior. Over the test duration, the sound pressure level increased by an average of 6 dB for the POM–PA66 gear pair and 4 dB for the Steel–POM combination. Concurrently, the RMS vibration amplitude rose from 21 m/s² to 45 m/s² for the POM–PA66 configuration and from 18 m/s² to 38 m/s² for the Steel–POM pair. This increase in vibrational response is attributed primarily to elevated transmission error induced by gear wear. Černe et al. (Ref. 11) previously characterized this phenomenon through numerical simulation, reaching comparable conclusions.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next NVH Measurement

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.