The quality of HRB-Expander series products has been improved by 3 times, making it more suitable for the high-end market.

Quality is the foundation of products. Today, with the turbulent development of the bearing industry, companies must strictly abide by quality if they want to ride the wave of competition. Only by creating first-class quality can we create first-class products, and only by having first-class products can we remain invincible. Harbin Bearing Group Co., Ltd. makes full use of its resource advantages and promotes the company's transformation and upgrading towards the goal of developing mid-to-high-end series products by establishing a sound and reliable quality assurance system and strengthening quality monitoring of the production process.

Product upgrade

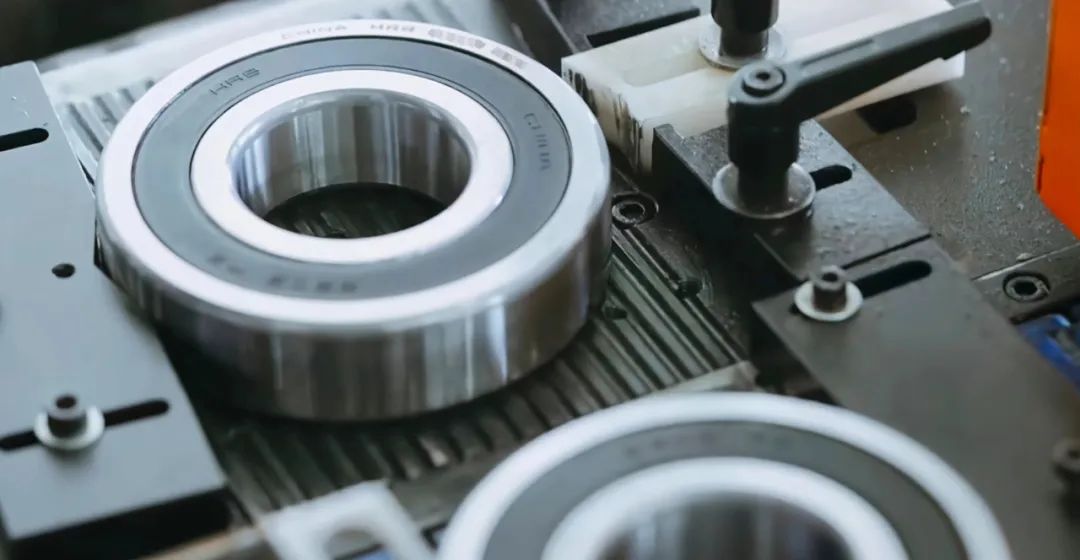

Harbin Bearing Group Co., Ltd. relies on advanced production and processing equipment and fully automatic processing technology to comprehensively improve the ultra-high speed, low friction and low vibration of bearings on the basis of ensuring product rotation accuracy and stability, focusing on special-grade high-purity bearing steel. performance. In March this year, the company launched a new generation product series HRB-Ex-pander and a high-end product series HRB-Climber. This series of products is more suitable for mid-to-high-end host applications in my country, starting the "HRB" brand to go high-end. The road to quality. The overall performance of HRB-Expander series products has been upgraded. The heat treatment effectively controls the amount of internal retained austenite below 5%. The stable fully automatic processing technology ensures that the product rotation accuracy reaches P5 level or above. The HRB-Climber series is HRB's high-end precision product, with excellent accuracy and long life. It has better performance in ultra-high speed, low friction and low vibration. The product geometric accuracy can reach P4 level, and the rotation accuracy can reach P2 level. , the life span can reach more than 3 times of similar products.

The quality system operates fully and effectively

By optimizing and upgrading the existing ISO9001 quality management system and cooperating with corporate business strategic planning, the company has improved management systems such as IATF16949 (quality) and ISO14001 (environment). At the same time, we carefully summarized the experience and lessons learned in the implementation of the quality management system in recent years, reorganized the system process, standardized management, and improved communication efficiency at the internal audit, external audit, management review and other levels. In order to improve the company's comprehensive competitiveness, the company has introduced a group of outstanding management talents this year. Through a series of internal management training and other activities, it has not only laid a solid foundation for improving employees' work quality, basic management levels and production efficiency, but also It also fully mobilized the enthusiasm of employees, achieved full participation, and promoted quality improvement through excellent system operation.

Strengthen process quality monitoring

HRB bearing takes "zero defects" as the company's eternal quality control goal and comprehensively improves core production stability, process discipline and quality control capabilities. For example, arrange for in-factory inspection and acceptance personnel to monitor process quality to ensure that the entire product process is under control; implement quality responsibilities for top leaders, establish a first-level supervisor movement management and quality problem list mechanism to ensure timely improvement when problems are discovered; and improve measures to improve customer complaints. Track the implementation and establish an experience and lesson analysis system; use quality tools such as 8D to find out the real causes of problems and determine effective improvement measures; give full play to the role of quality engineers in each production unit to solve the quality bottleneck problems of branch factories in a targeted manner; establish quality The Kanban management system promptly releases process quality issues and improves employees' awareness of process quality and improvement. Quality is not determined by inspection, production, or design; quality is not determined by management, but by habit. In the future, HRB bearing will continue to maintain a good situation in which everyone cares about quality and attaches great importance to quality, and will make unremitting efforts to improve the quality of the company's products, so that the company's product quality will continue to climb to new levels and win business opportunities in the market.

ABOUT HRB

Harbin Bearing Group Co., Ltd. was founded in 1950, is one of the 156 key projects during China's "First Five-Year Plan" period, is one of the three major production bases of China's bearing industry, registered trademark "HRB", registered capital of 650 million yuan, total assets of 1.6 bilion yuan in 2021, the total number of employees of more than 1,800 people, Can be a series of production of inner diameter 1mm to outer diameter 1000mm nine types, various accuracy levels of more than 8000 specifications and varieties of bearings. HRB bearing production base covers a total area of 410,000 square meters. HRB Bearing Group Co., Ltd. has a sound channel sales network, the sales network covers 34 provinces and autonomous regions, and exported to Europe, South America, Southeast Asia and other countries and regions. Products are widely used in aviation, aerospace, navigation, precision machine tools, industrial robots, motors, automobiles, rail transit, metallurgy and mining, agricultural machinery, chemical machinery and household appliances and other industries, can also provide high-speed, high temperature, low temperature, rust, anti-magnetic and other special purpose bearings.

Harbin Bearing Group has a national technical center, Through the national 11th Five-Year science and technology support project "high-speed railway passenger car bearing key technology research", the 12th Five-Year science and technology support project - "Urban rail transit bearing key technology research", "precision CNC machine tool spindle bearing key technology research", "high-end CNC machine tools and basic manufacturing equipment" national major science and technology research. Harbin Bearing Group has completed the technical and industrial upgrading of traditional advantageous products, mass production of P2 universal assembly ultra-high speed angular contact ball bearings, new structure ultra-high speed angular contact ball bearings, cylindrical roller bearings, YRT high-speed CNC turntable combination bearings, precision bearings with an annual output of more than 700,000 sets. Harbin Bearing Group has established a sound scientific and standardized quality management system, and has passed ISO9001:2000 quality system certification, so that the quality management system is in line with international standards. In 2005, it won the title of "China Famous Brand" products.

In August 2020, Harbin Bearing Group began to restructure, and the new Harbin shaft was introduced into the management system structure of Jianlong Group, and it is committed to creating a specialized, fine, special and new bearing enterprise. The new Jianlong Harbin Bearing headquarters is located in Jiangbei Bearing Industrial Park, No. 777, Haxiang Road, Hulan District, and has been ficially put into use in August 2021. In the future, Harbin Bearing Group will focus on the three production bases of Jiangbei Bearing Industrial Park, Harbin Southern Automobile Bearing Industrial Park and Dalian Huanghai Motor Bearing Industrial Park, develop medium and high-end bearings, actively build innovation-leading enterprises, give full play to the demonstration role of leading enterprises in Heilongjiang Province, and strive to become a national bearing industry base. Focus on the development of precision machine tools, automobiles, motors, rail transit, metallurgy, mining and military and other high-end bearings, using HRB brand advantages,accelerate the pace of expansion, to the world's leading level of bearing research and development expansion, towards the international market, for the bearing industry construction and development to contribute more strength, in the bearing industry out of a new route, HRB brand into China's first bearing brand, among the world's first-class bearing brands.

Contact HRB

Company:Harbin Bearing Group Co., Ltd.

Address: NO.777, Haji Road, limin District, Harbin,China

Tel: 0451-87902581

Email: liugw@hrb.asia

More information

More information| Contact information | |

| Company name: | Harbin Bearing Group Co., Ltd. |

| Contact person: | Mr.Zhang(Click to contact) |

| Address: | NO.777, Haji Road, limin District, Harbin,China |

| Zip: | 150036 |

| Telephone: | You need register first! Register Now ! |

| Fax: | +86-451-55669879 |

| Web site: | http://www.hrbchina.com |