End mills machine nickel-based heat resistant alloys

Published on:28 Jan,2016

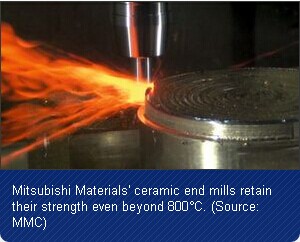

Cutting Tools – Mitsubishi Materials has developed a line of ceramic end mills, the CESRB series, which is said to be ideal to machine nickel-based heat resistant alloys such as Inconel 718.

The composition of these materials sees them soften when heated to temperatures beyond 800°C, making them easier to machine. Whereas cemented carbide end mills deteriorate drastically when working beyond 800°C, the new range of ceramic end mills retains its strength, the company claims. This is said to enable high-speed machining with large depths of cut and at high feed rates on these difficult-to-cut materials. Capable of working at parameters beyond that of carbide end mills, ceramic end mills can double tool life whilst machining at feeds and speeds up to 10 times higher than conventional tools.

The concept behind this new range is that it should run without coolant at high speeds and feeds with relatively heavy depths of cut to generate higher frictional heat, Mitsubishi explains. By generating an increase in temperature, the component material softens and enables the end mill to work more efficiently. As such, the Mitsubishi R&D department suggests that these new end mills operate at speeds from 13,000 to 26,000 rpm depending upon tool diameter with feed rates in the region of 1.5 to 2 m/min.

Ideal for Inconel applications in the aerospace and power generation sectors, the performance of the new CESRB range is credit to its ceramic composition and the innovative geometry, the supplier says. The creative geometry design incorporates an optimised helix angle that reduces cutting forces and prevents the 'pull-out' effect that is common during heavy machining. Furthermore, Mitsubishi has utilised its seamless grinding technology to deliver a higher edge chipping resistance, even during extreme roughing applications. These features are said to be supported by a strong negative flute and specially developed rake edge that withstands high temperatures and loads.

The tools are available with a four-flute design for pocketing and slotting operations, whilst a six-flute design is available for face and profile machining. The four and six-fluted end mills are available in diameters of 6, 8, 10 and 12 mm with a corner radius of 0.5, 1 and 1.5 mm depending upon the chosen diameter.

Mitsubishi recommends that customers utilise a robust machine tool with a sturdy tool clamping configuration.