ZF Produces sMOTION Active Chassis Dampers

Published on:12 Dec,2024

A new era of damping technology has begun as sMOTION from ZF is now bringing stability and dynamics together for improved comfort and driving performance. This system adapts damping force exactly to the corresponding driving situation while also initiating very fast vertical movements for each individual wheel, thus actively lifting the vehicle to ensure optimal roadholding performance while enhancing a more pleasurable driving experience. This capability from sMOTION creates a unique driving experience. The system's damper technology is now being used in two new models of a German premium manufacturer.

In the case of automotive chassis, it has often been challenging to combine excellent dynamic properties with high-level comfort. That has been made easier for automakers with sMOTION as the pitching and rolling maneuvers inevitable in dynamic steering, braking and acceleration have been virtually eliminated.

"Our fully active sMOTION chassis system can almost completely prevent vehicle body movements in certain driving situations," explains Dr. Peter Holdmann, member of the board of management at ZF and head of the chassis solutions division. "At the same time, the comfort characteristics of vehicles equipped with sMOTION increase significantly.”

Two new Porsche models already make use of part of ZF's sMOTION active suspension system – the Panamera and Taycan. Each features Porsche’s “Active Ride” air suspension which uses sMOTION’s damper and valve technology.

sMOTION sets standards for driving comfort, dynamics and safety

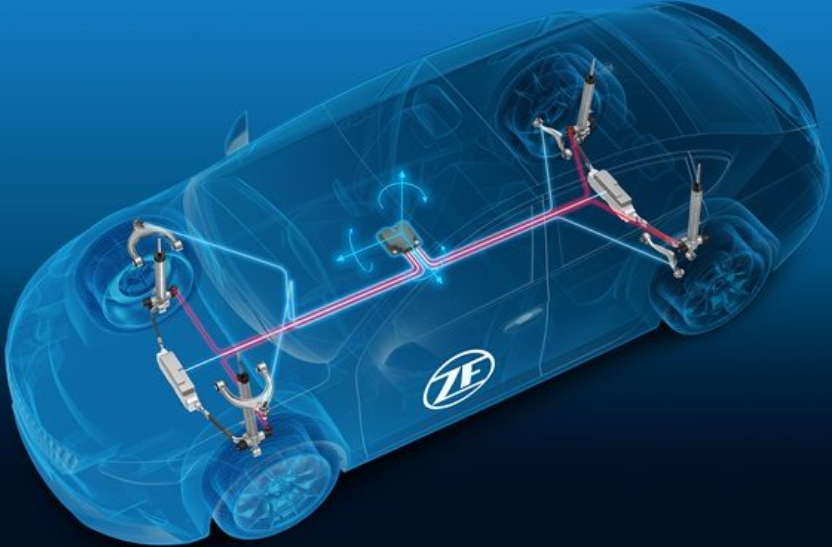

The sMOTION active chassis system is based on the well-known, adaptive ZF damping system CDC (Continuous Damping Control) with two external valves, each of which independently regulates the compression and rebound direction of the damper. In this way, damping pressure is optimally adapted to the respective driving situation, an important quality for driving comfort and dynamics. sMOTION goes a step further using a high-performance oil pump to actively move the wheel suspension via the piston rod. In this way, the electronic control system can neutralize the effect of road unevenness on individual wheels. It is also able to compensate or even counteract the wheel height when cornering - for example, when accelerating and braking.

Active vertical movement of the wheels

sMOTION is particularly powerful during dynamic driving maneuvers: A sharp steering movement to the right would normally cause a conventionally damped vehicle to "tilt" to the left. Passenger cars equipped with sMOTION, automatically adjust the cornering inclination to the speed and generate a "helicopter mode." Thus, the vehicle's driving behavior is almost light-footed.

For example, a vehicle equipped with sMOTION can use the active damper system, to elevate a vehicle by eight centimeters within half a second. This means the control electronics, also developed by ZF, can hold a passenger car weighing three tons almost horizontally on the road up to a cornering force of 1 g.

Motion sickness: Minimize causes

This wheel-specific active body control, which does not use stabilizers, has significant potential in terms of comfort. If vertical movements of the vehicle body are prevented, so-called "motion sickness" can be potentially eliminated.

"Our system virtually eliminates motion sickness, which today primarily affects passengers reading or watching films while traveling," explains Thomas Kutsche, vice president engineering productline suspension at ZF. The calming of the vehicle body can be increased even further, for example if information on road conditions, such as bumps or potholes are known, which the system can compensate for in a targeted manner. If automated and autonomous driving continues to increase in practice, this chassis characteristic becomes increasingly valuable for all vehicle occupants.

Expansion of ZF's system portfolio – 25 years of CDC

With sMOTION, ZF is adding to its portfolio for passenger car steering, braking and chassis. With these electronically controlled actuators, ZF can influence the complete longitudinal, transverse and vertical dynamics of vehicles as a software-controlled overall system. In the future, the combination of these technologies will lead to networked chassis systems that can be coordinated holistically with the ZF cubiX software: "We can support manufacturers not only with the components, but also with software driving functions for the overall system," says Holdmann.

ZF is among the top technology suppliers when it comes to semi-active and active damping systems. The first CDC system came onto the market 25 years ago and sMOTION uses the latest generation of CDC technology, which is CDCrci with two valves on each damper – one for the rebound stage, the other for the compression stage.