NSK Releases Highly Reliable Spherical Roller Bearings for Wind Turbine Main Shafts

Published on:25 Dec,2024

Improved wear resistance delivers stable operation with less maintenance over long periods

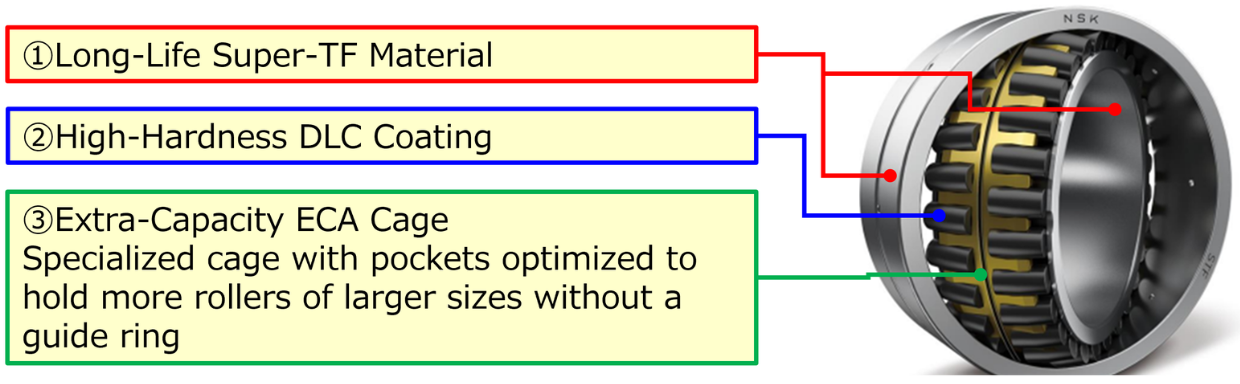

A NSK-first combination of bearing material, roller coating, and extra-capacity cage for reducing wear

A total solution for higher durability—Over 90% less raceway wear compared to standard products

NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Akitoshi Ichii) has developed and launched a line of highly reliable spherical roller bearings (SRBs)1 for wind turbine main shafts that combine three advanced technologies to deliver exceptional reliability. Joining NSK’s “Super-TF” long-life material and high-hardness diamond-like DLC coating, a new extra-capacity ECA cage provides high load capacity in a total bearing solution optimized for the challenges facing today’s wind turbines.

By the full application of these technological advancements, NSK has reduced raceway wear to less than one-tenth that of standard products. As raceway wear is the main form of damage in SRBs for main shafts, this provides a substantial improvement in bearing durability. With fewer maintenance runs and less need to replace parts, these highly reliable bearings help reduce downtime and maintain stable operation at wind power generation facilities worldwide.

NSK has been serving the wind turbine industry with our Super-TF material and DLC coating for years. In June 2024, we developed a SRB with a new extra-capacity ECA cage to serve the needs of wind power companies in North America. Now, we have fully implemented a production system for highly reliable SRBs combining all three of these advanced technologies and we are now expanding fulfillment worldwide.

Future plans involve combining these SRBs with NSK condition monitoring solutions to expand business in maintenance, repair, and operations (MRO). NSK high-reliability spherical roller bearings join a portfolio of aftermarket offerings laid out in our 2026 Mid-Term Management Plan, with a target of 25 billion yen in increased sales in the sector over fiscal 2021.

1.Development Background

Any component failure in a wind turbine leads to expensive repair costs and extensive downtime. As wind turbines are installed in special environments, such as on mountains and offshore, parts replacement work and the procurement of parts, repair cranes, and other equipment to address damage can take substantial time and resources. Many large parts for wind turbines are made-to-order, and bearings for the main shaft are among the largest components used in machinery. Damage to these crucial parts can result in replacement work that requires about one year or more of downtime2. Therefore, bearings for wind turbine main shafts must be built to last—with high reliability and resistance to premature damage.

Bearings in the main shafts of wind turbines must support the heavy weight of the blades (vanes) and fluctuating loads from changing wind conditions. Spherical roller bearings are the solution of choice, with high load capacity and their ability to tolerate mounting errors and automatically correct for deflection of the shaft or housing (self-alignment). Heavier-than-expected loads under severe operating conditions are the main culprit behind premature damage in SRBs. These factors prevent the necessary oil film from forming in the area between the rollers and bearing rings. Without this lubrication, wear occurs, requiring the bearing be replaced earlier than expected. Thus, improving the wear resistance of raceway surfaces is crucial for turbine uptime and operational reliability.

2. Benefits & Features

1) Improved wear resistance

High-reliability spherical roller bearings for wind turbine main shafts reduce raceway wear by 90% or more compared to standard products. As raceway wear is the main form of damage in these SRBs, NSK’s high-reliability solution boasts significantly improved bearing durability.

2) Application

Stable turbine operation for extended periods—High-reliability spherical roller bearings extend maintenance intervals and reduce unexpected replacement downtime.

3 .Product Technologies

NSK core technologies in materials, tribology, and analysis combine to provide exceptional resistance to raceway wear. In an NSK first, Super-TF material, a DLC coating, and a high-load capacity cage are combined in a single bearing product.