Applications

Paper Mill Bearings

Description:

A paper mill is a factory devoted to making paper from vegetable fibres such as wood pulp, old rags, and other ingredients.The typical requirements of paper-making machinery for bearing configuration are:

• Very high operational reliability

• Easy to install

• Compensation for misalignment

• Avoid corrosion in the wet part

• High temperature adaptability of cadres

• High speed adaptability

• High-quality and high-precision bearings

SXM knowing paper mill real conditions and develop specialized bearing for Paper Mill Machinery, the bearings have the following functions:

• Specially designed Cylindrical and taper hole

• Big clearance(C3 or C4)to bear high temperature and impact

• SXM bearings with high precision grade and high rotation accuracy(P5)can rotate with high speed. High speed, high reliability and long life bearings make good quality paper.

• Increased shaft temperature increases the mating stress. SXM use high quality type A steel to resist cracking of the inner ring.

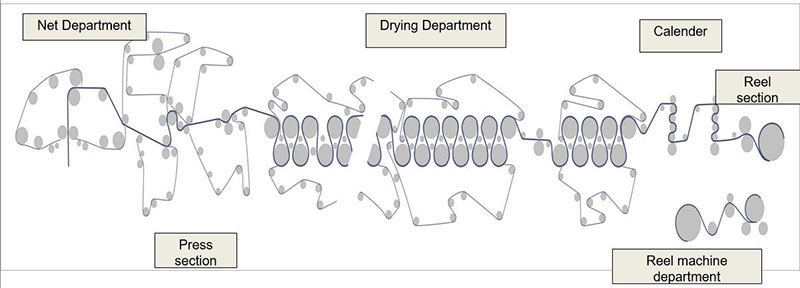

A modern paper machine production line generally consists of:

SXM designs different series of bearings for different section in paper production line.

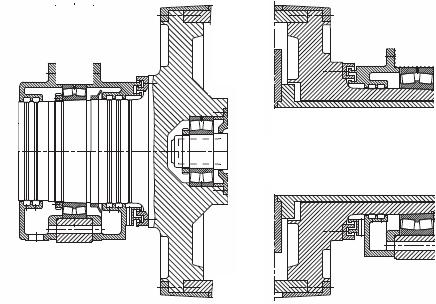

1. Vacuum roll

Vacuum rolls are used for dewatering the web.

The vacuum roller is composed of a roller body, a vacuum box, a paper blowing pipe, a water spray pipe, an adjusting screw, a pressure, and a vacuum indicating instrument.

The bearing is installed on the roll body and the vacuum box.

Case: Bearing configuration of 4800mm corrugated paper machine

The production line has a width of 4800mm and a vehicle speed of 750m/min

We recommend SXM 23076CA/C3W33,23096CA/C3W33 and 23330CA/C3W33.

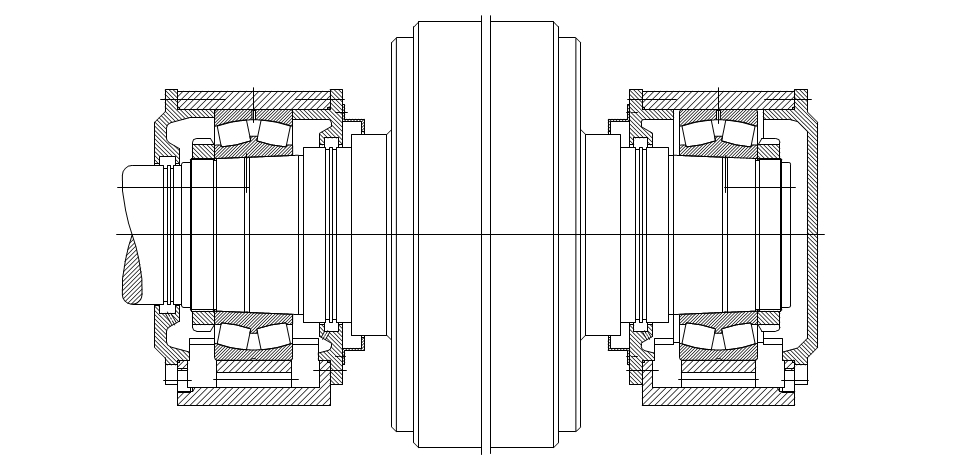

2. Center press roll

When the paper web passes through the press roll on the felt, a large amount of water is pressed out. In the press section of a modern paper machine, one or more (suction) press rolls are pressed against the central press roll. The center press roll is a solid roll made of granite/steel or steel with a protective layer.

Case: Bearing configuration of 4800mm corrugated paper machine

The production line has a width of 4800mm and a vehicle speed of 750m/min.

We recommend SXM bearing 23192CAK/W33.

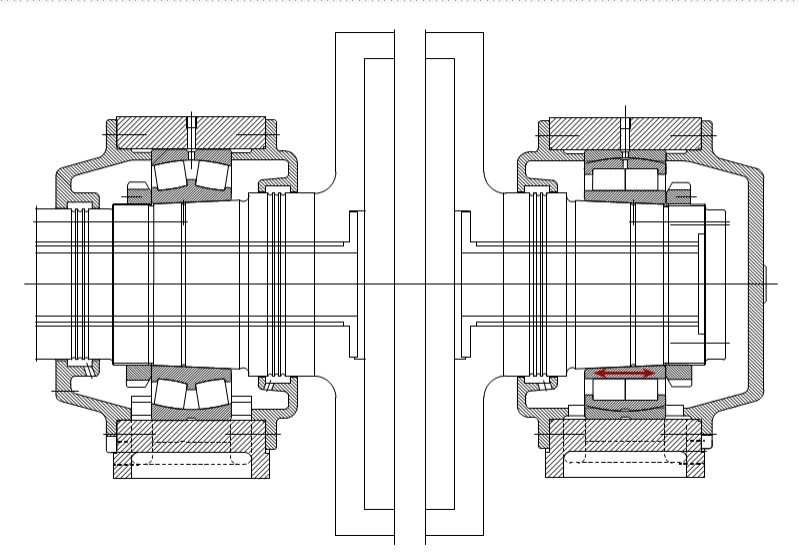

3. Dryer

The remaining moisture of the paper web evaporates in the dry part. The paper runs on many heated drying cylinders, which are guided by an annular drying net (formerly a drying felt). The drying cylinder is heated by steam (the temperature is determined by the paper type, paper thickness, papermaking speed and the number of drying cylinders). The high temperature of the heating steam is transmitted to the bearing mating surface and correspondingly increases the bearing stress.

The bearing load is calculated based on the roll weight, felt tension and temporary water filling.

The heating phase will cause a maximum temperature difference of about 50 ℃ between the inner and outer rings, and the spherical roller bearing has an enlarged radial clearance C4. Due to the high operating temperature, the inner ring of the bearing undergoes special heat treatment (constant temperature quenching), so that the bearing size can remain stable up to 200 ℃.

Case 1: Bearing configuration of 4800mm corrugated paper machine

The width is 4800mm and the speed is 750m/min.

We recommend SXM bearing Φ1800*5250 dryer bearing 23144CCK/C4W33.

Case 2: Bearing configuration of 2400 special paper machine

Width 2400mm, vehicle speed 500m/min

We recommend SXM bearing 22236CK/P53S1W33-1.