Angular contact ball bearings are not necessarily used in pairs. The angular bearing is also called a radial thrust bearing. The structure is that the bearing rollers form a fixed angle with the axis, thereby generating both centripetal force and axial force, which can also play the role of centering and bearing. It is equivalent to installing a plane bearing and an ordinary cylindrical bearing at the same time. Therefore, angular bearings are used on rotating shafts that need to carry constant axial forces. However, if the axial force is unidirectional, it is not necessarily used in pairs. As long as there are angular bearings that can only contend with the axial force.

The paired use of angular bearings is generally used on shafts with high precision and bidirectional force. For example, the spindle of the CNC machine tool and the screw of the CNC servo axis. Because the movement process of these shafts is very complex, there are often forward and reverse rotations, and it is required to be correspondingly rapid when the shaft is reversed, and there is no axial play. So it must be used in pairs. In order to prevent the shaft from swaying in two directions. achieve the purpose of stabilizing the movement.

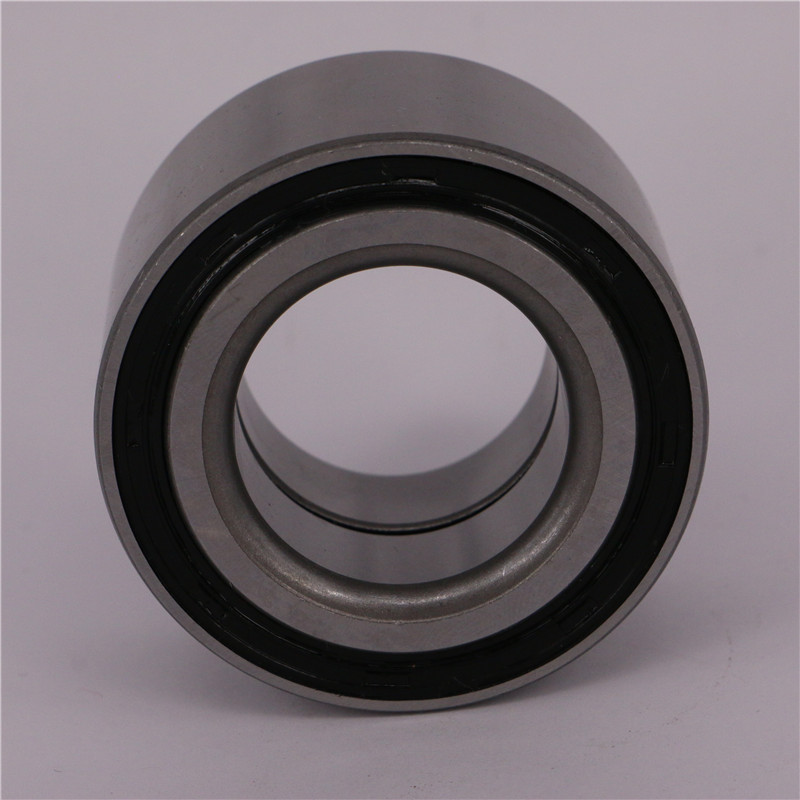

Angular contact ball bearings are generally divided into single row angular contact ball bearings and double row angular contact ball bearings, both of which have different functions.

Single row angular contact ball bearings can only bear axial loads in one direction, and additional axial forces will be caused when bearing radial loads. And can only limit the axial displacement of the shaft or housing in one direction. Angular contact ball bearings have a contact angle of 40 degrees, so they can withstand large axial loads.

The angular contact ball bearing is a non-separable design, and the shoulders on both sides of the inner and outer rings are not high and low. In order to increase the load capacity of the bearing, the shoulders on the side are machined lower so that the bearing can fit more steel balls.

Double row angular contact ball bearings can withstand larger radial loads and combined radial and axial loads and moment loads, limiting the axial displacement of the shaft on both sides. The inclination between the inner and outer rings of the double row angular contact ball bearing is limited in the components that are mainly used to limit the bidirectional axial displacement of the shaft and the housing. The allowable inclination angle depends on the internal clearance of the bearing, bearing size, internal design and the effect on The forces and moments on the bearing, and the allowable inclination angle should ensure that excessive additional stress is not generated in the bearing. If there is an inclination angle between the inner and outer rings of the bearing, the service life of the bearing will be affected, and at the same time, the running accuracy of the bearing will decrease and the running noise will increase.

Double row angular contact ball bearings generally use nylon cage or brass solid cage. When installing the double row angular contact ball bearing, it should be noted that although the bearing can bear bidirectional axial load, if there is a gap in the side of the ball, care should be taken not to let the main axial load pass through the side groove edge with the gap. When the bearing is used, care should be taken to make the side raceway without the ball-loading notch bear the main load.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.