igus smart plastics for industry 4.0 predictive maintenance

Learn more about igus smart plastics, new technologies designed to enable Industry 4.0 applications. This evolution of proven igus cable, energy chain and linear bearing products embeds intelligence into its motion plastics via the addition of sensing, monitoring and communications. Using smart plastics, customers can increase plant availability, maximise uptime and reduce costs through condition monitoring and predictive maintenance.

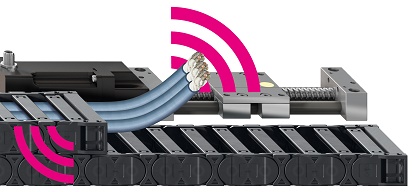

igus smart plastics represent the next step for motion plastics: adding intelligence and networking to enable Industry 4.0 smart factories via automated condition monitoring and predictive maintenance, improving reliability and reducing costs. Intelligent cables, energy chains and linear guides continuously monitor themselves, providing performance data and early warning of critical wear. isense encompasses a range of sensing technologies and monitoring modules, while networking with the icom communication module provides direct integration with the customer's IT infrastructure, and optionally the igus data cloud.

isense continuously monitors the service life of your e-chain, cable or linear guide via real-time sensor measurements and calculations using the parameters of your system. These measurements are referenced against aggregated test data from the extensive igus test laboratory database to reliably predict service life and smooth functioning in real-world operation. Alerts are sent when measured values exceed thresholds, allowing timely maintenance or replacement.

Find out more about igus smart plastics and view a short video at: www.igus.co.uk/smartplastics

For more information, please contact:

igus

Caswell Road

Brackmills

Northampton

NN4 7PW

Tel: +44 1604 677240

Fax: +44 1604 677245

Email: sales@igus.co.uk

Web: www.igus.co.uk

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.