MinebeaMitsumi has succeeded in developing its new product-High Sensitivity Strain Gauge Film

MINEBEA MITSUMI Inc. ( “MinebeaMitsumi”) has succeeded in developing its new product, the High Sensitivity Strain Gauge Film.MinebeaMitsumi has conventionally held an industry top-level share in load and force sensors using strain gauges.1 As the result of 15 years of R&D, we have succeeded in developing a world-pioneering High Sensitivity Strain Gauge Film. By applying of metal resistance material using our

unique manufacturing method, the new gauge succeeds in realizing high sensitivity of over 500% and Miniaturization to less than 1/10 of the conventional size more than conventional products.

Strain gauges are used by affixing to an elastic body (such as metals). The elastic body to which a strain gauge can be affixed has until now been limited in terms of design due to the need to select materials that secure sensor characteristics. But with the development of the new gauge, these design limitations are significantly alleviated due to its high sensitivity characteristics which enable increased freedom of selection of the elastic body to which it is affixed.

Moreover, due to miniaturization, it has become possible to install the new gauge to minute measurement points where it could not previously be used. Furthermore, since the gauge takes the form of a film, it is suitable not only for miniature size but also can be produced and supplied for various large and small-size.

Ultra-precision Sensing to Enable Desired Input

In contrast to conventional switches, the new gauges realize switching among multiple functions using a single switch by sensing the strength of the touch force in multi-stages, enabling application to mobile and

wearable products where miniaturization and multi-functionality continues to progress. This can contribute to the realization of product miniaturization and improved energy-saving. In addition, in the future, we anticipate application to touch sensors in the expanding robotics market, to realize fine movement similar to

human movements, by sensing delicate hand movements with dexterity like those of an artisan and minute forces like those of the touch of a fingertip. The new gauges will also be able to be applied flexibly in the future in accordance with customer design needs for uses such as in-vehicle applications.

We expect that the new gauges will be applied to a wide range of uses in a wide range of areas in addition to these and make a significant contribution to sensing in the IoT era.

Sensing Systems that Utilize Technological Synergy from MinebeaMitsumi Business Integration

In parallel with the development of the new gauge, we proceeded with the development of analog-digital conversion circuits from the semi-conductor business of the former Mitsumi Electric Co. Ltd., and we plan to simultaneously provide new gauge sensor systems too, consisting of new gauges + conversion circuits.

These will be our first concrete new products which realize the technological synergy of the former Minebea Co., Ltd. and the former Mitsumi Electric Co. Ltd.

Aticipated sales of several tens of billions of yen

We intend to prepare for mass production during fiscal 2017 and begin dispatching samples from April 2018. Our business target is to develop new markets and increase our share in conventional markets, to

realize anticipated sales of at least several tens of billions of yen and we anticipate that this product will become a key product to support our electronics business.

As a provider of Electro Mechanics SolutionsTM 2 who contributes to the IoT era, MinebeaMitsumi combines a broad range of advanced technologies—from high precision machine processing technologies such as bearings, to motors, sensors, semiconductors and wireless technologies—to create new value through “difference” beyond the realm of common sense.

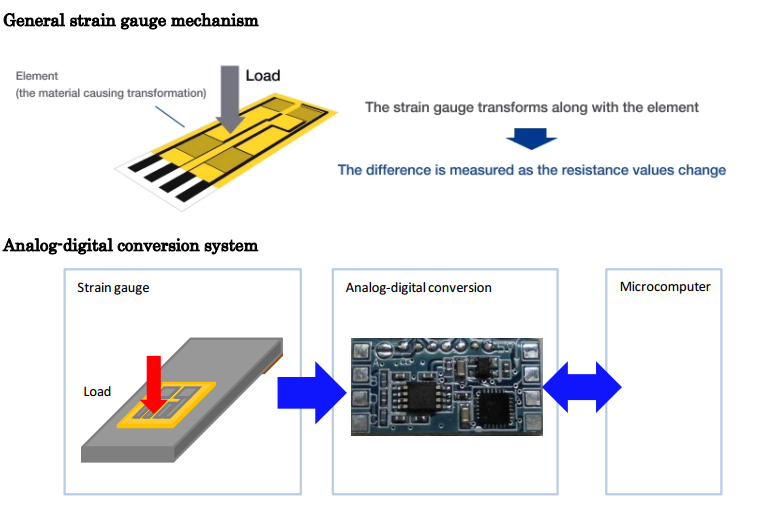

About Strain Gauges

Strain gauges are sensors that read changes in load (force) and torque as resistance which they then convert into electrical signals. When a load (force) is applied to the object to which a strain gauge is affixed, the strain gauge mechanism works by expanding and contracting along with the object, changing the resistance value of the gauge and measuring the load (force) as the amount of change.

MinebeaMitsumi’s strain gauges are light-weight in mass and feature the merit of enabling direct measurement of desired measurement locations since they can be affixed directly, in contrast to similar sensors such as Micro Electro Mechanical Systems (MEMS) sensors that

require board mounting. As a result of this, MinebeaMitsumi’s sensor products that use strain gauges enjoy a large market share.

Because these strain gages are so small that they are negligible in mass, they excel in sensitivity, stability and fatigue with no inertial effect. They are also an easy-to-handle device,whose operating temperature range is wide. All kinds can be used to measure with the self-temperature compensation for all materials with various thermal expansion coefficients to be measured, regardless of metal or plastic.

Conventionally, MinebeaMitsumi did not include analog-digital conversion circuits or standard amplifier circuits in its product line-up. But on this occasion, in accordance with the development of the new strain gauge and in pursuing technological synergy with the

former-Mitsumi Electric Co. Ltd.’s semi-conductors, in terms of signal processing, we have created an analog-digital conversion system solution which makes optimal use of the features of the new gauge and uses circuits such as AFE (Analog Front End) and ADC (Analog-to-Digital Converter) in standard products. This enables the provision of a sensor system with sensors that can be tuned more easily than conventional gauges, to contribute to flexible sensing in the IoT

era.

Patents

MinebeaMitsumi has applied for 40 patents relating to the structure and manufacturing method of the High

Sensitivity Strain Gauge Sensor.

1 A sensor that reads changes in load (force) and torque as changes in resistance and then converts these into electrical signals.

2 "Electro Mechanics Solutions" is a registered trademark in Japan of MinebeaMitsumi Inc. Its registration No. is 5322479.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.