Continuous Power Enhancement

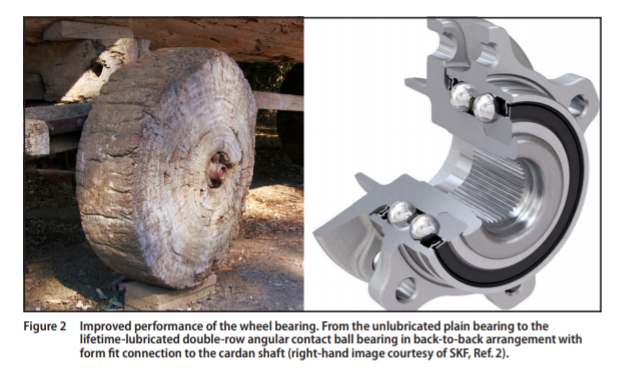

The evolution of machine elements and

their future as an element of design are

analyzed here using the example of

rolling bearings and gears. Due to the

bearing as a functional unit, the invention

of the wheel about 6600 years ago

became a sustainable innovation. With

the wheel centered and guided by the

bearing, the acting forces were supported

(Fig.2, left). A modern wheel

bearing has the same basic functions,

can also transmit the drive power practically

without loss and, in many cases,

also provides high-resolution rotational

speed information via specific sensors

(for example, in a modern ABS system).

A similar development can be observed

in the example of linear guides

(Fig.3). Whereas about 4600 years ago

wooden rollers as rolling elements facilitated

the construction of pyramids,

with modern slides guidance accuracies

in the range of micrometers are possible due to advances in manufacturing

technology for the hardened and

precision-ground rolling elements as

well as the preload of the rolling contacts.

An integrated position measurement

system can resolve the same

accuracy. Low-friction seals and optimized

rolling contacts have made it

possible to continuously reduce friction

losses over the past decades.

Moore’s Law

In 1965, Gordon Moore made a prediction

about the development of semiconductor

technology (Ref.1). His prediction

is known as Moore’s law and

states that the number of transistors per

unit area will double every year, corresponding

to an exponential increase.

Moore’s law has so far proven to be

largely correct. However, the further reduction

in the size of transistors is likely

to reach its limits in the coming years.

Alternatives to conventional transistor

design or new approaches to chip

architecture are needed for the future

(Ref.3).

Whether Moore’s law can also be applied

to machine elements will be considered

in this section. In order to be

able to assess the further development

of machine elements and the technical

systems assembled from them, suitable

quantification on the basis of technical

characteristics is necessary.

Torque Density of Gearboxes

for Wind Turbines

In wind turbines, the increasing rotor

diameters led to an increase in the rated

power. At the same time, a reduction of

the rotor speed is necessary to maintain

the permissible blade tip speed (Ref.4).

This results in a high increase in input

torque. To evaluate the development of

gearboxes for wind turbines, the torque

density as a quotient of the rated torque

of the gearbox and the weight of the

gearbox is suitable (Refs. 5, 6).

Figure 4 suggests an annual increase

in torque density of about five percent.

This corresponds to an exponential increase

as in Moore’s law, although at a

lower growth rate.

The development of torque density

is due, among other things, to lightweight

construction, new materials and

coatings, and optimized macro- and micro-geometries (Ref.6). Smaller

plain bearings allow higher power densities

by load sharing on more planets

and enable new gear concepts (Ref.7).

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.