Bosch Rexroth Adds Force Control Feature to Mechatronic Subsystems

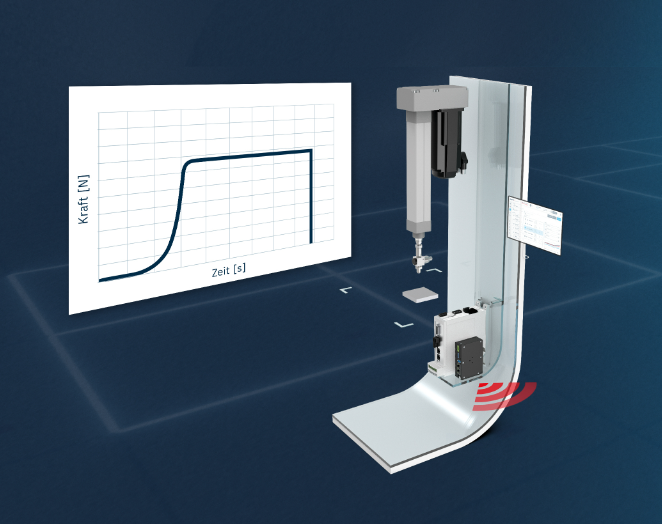

The Smart Function Kit Pressing, a complete mechatronic package from Bosch Rexroth for the quick realization of servo presses, is now available with force control. This means that it is now also possible to perform processes in which the target force must be kept constant over a defined period of time. Intelligent e-tools speed up the selection and configuration of the modular servo press. The pre-installed operating software facilitates quick and easy commissioning, process definition, and line integration.

With the newly integrated force control software feature, the Smart Function Kit Pressing covers a total of three types of applications: joining to a defined position (position controlled), joining to a defined force (position controlled), and new: joining to a defined force with subsequent maintenance of the force (force controlled).

When joining with force control, the servo press maintains a constant defined target force for a predetermined duration, even if the position of the workpiece fluctuates or its size changes. This is the case, for example, if it expands or shrinks in the process, melts, or is ground off. Continuous monitoring of the maximum force and position values protects the system and tool from damage. You can switch the curve view from force/position to force/time for better process representation and analysis.

Force-controlled joining is required in many manufacturing and assembly processes, such as in powder pressing, laser welding, or grinding. Another field of application is material testing. In battery production, for example, pouch cells are tested for tightness with constant force while the material expands with the addition of heat. In fuel cell production, the Smart Function Kit compresses components made of different materials with a defined force over a period of several minutes while introducing heat.

Save time from engineering to monitoring

The correct size of the Smart Function Kit can be determined very easily using the new "-Press in/force control" reference process in the LinSelect sizing tool. Integrated safety functions (safe torque off or safe motion) are also available as selectable options in the seamlessly connected online configurator. CAD data and technical documentation can then be downloaded free of charge and the servo press can be ordered directly from the Rexroth online shop with one material number.

The Smart Function Kit for pressing and joining applications consists of the standard components electromechanical cylinder with force sensor, servomotor, drive controller and industrial PC, and is supplied pre-assembled in one package. The pre-installed browser-based operating software shortens commissioning to a few minutes, programming is done graphically via sequence modules, whereby plausibility checks prevent the system limits from being exceeded.

The Smart Function Kit Pressing can easily be connected to a higher-level controller in the place of use by means of prepared function blocks. From there, commands can be given to the servo press, and results and process data can be transmitted to it.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.