【New breakthrough in wind power industry】:China independently developed and produced sliding bearing gearbox has achieved zero failure

At the CGN Yuantong Sankeliu Wind Farm in Tongyu, Jilin, 30 smart wind turbines have been using sliding bearing gearboxes independently developed and produced in my country for three years and have achieved "zero failure". This is the first time that sliding bearing gearboxes have been mass-applied in the domestic wind power field, verifying the feasibility and reliability of this technology in wind power application scenarios.

According to the relevant person in charge of the wind farm, compared with traditional rolling bearing gearboxes, sliding bearing gearboxes can reduce power losses by about 20%-25%. This means that under the same input conditions, the power generation of wind turbines can be increased by about 0.5%. Taking a 3.3MW onshore wind turbine as an example, it can generate 1,075,140 more kWh of electricity during its entire life cycle, which is equivalent to the annual electricity consumption of 360 households.

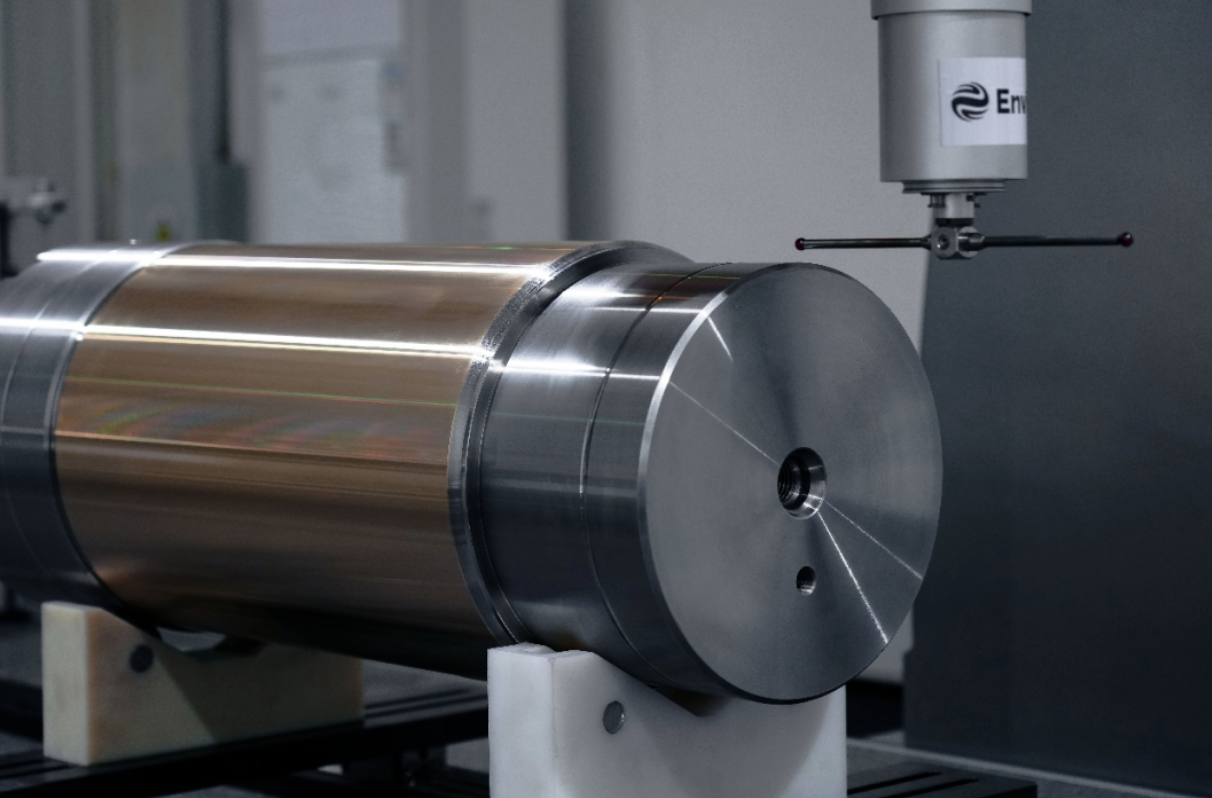

These gearboxes are produced by the Envision Energy Transmission Chain Factory in Jiangyin, Jiangsu. Lou Yimin, senior vice president of Envision Energy, pointed out that the successful application of sliding bearings is due to in-depth technical research, breakthroughs in the melt-spray coating technology route, and strict standards and precision testing in the manufacturing process. In addition, Envision has ensured the high reliability and high performance of its products through in-depth mining of massive data and a deep understanding of wind turbine operating conditions.

As wind turbine capacity continues to increase, the application of traditional rolling bearings has reached its limit. Sliding bearings have become an ideal choice to support the continued large-scale development of wind turbines due to their small size, light weight, and low power loss. Especially for wind turbine equipment with long life requirements, sliding bearings can better meet the full life cycle requirements of 25-30 years.

Domestic wind power manufacturers began to explore the research and development of sliding bearing gearboxes as early as five years ago. At present, only Envision Energy has achieved self-development and self-production of sliding bearings and has the ability to mass produce them. As of 2023, Envision Energy's offshore wind turbines equipped with sliding bearings have been connected to the grid in Shandong waters, and more than 100 wind turbines have maintained a "zero failure" record.

The technical difficulty of sliding bearings lies in their complex manufacturing process and strict cleanliness control. For example, a wear-resistant and thin protective layer is added to the bearing surface through melt-spray coating technology, and then a series of precision processes are performed to ensure product quality. Envision Energy not only focuses on product design and manufacturing, but also simulates various actual working conditions during the test and verification process to ensure that the performance of components meets the requirements.

The successful application of the sliding bearing gearbox not only marks a major technological advancement in China's wind power industry, but also provides valuable experience for the application of sliding bearings in other industrial fields. Sliding bearings also have broad application prospects in the fields of automotive gearboxes, marine engines, etc., and their breakthrough progress will promote the development of the entire high-end basic parts industry. This achievement reflects the leapfrog development of China's wind power industry from following to leading, and demonstrates the strength and responsibility of Chinese companies in global technological innovation.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.