Accelerating gearbox development through intuitive, system-level engineering tools that adapt to any workflow

The KISSsoft System Module streamlines variant development by managing component models, visualizing concepts, and enabling efficient collaboration across engineering teams, supporting data integrity, cost control, and seamless integration.

Speed is a key factor for success. It is as important as cost, value, uniqueness, vision, user acceptance. This holds true for processes, goods and services. And for tools, including the one presented here. A tool that is intuitive to use requires little time to learn. A versatile tool is quickly accepted by a team dealing with many projects or concepts simultaneously. A tool that adapts to the users’ workflow and integrates seamlessly maintains these processes speed. Introducing the KISSsoft System Module.

Use Cases

CAE tools like the KISSsoft System Module play a crucial role in the sizing, optimization and rating of gears and other transmission components by addressing key design needs. It supports the design of new transmissions based on end user requirements, allowing for innovative solutions tailored to specific performance goals like reliability, vibration level or transmittable torque. In addition, the System Module is essential for modifying legacy systems to meet new operating conditions like the use of stronger engines, ensuring that older designs remain relevant and functional.

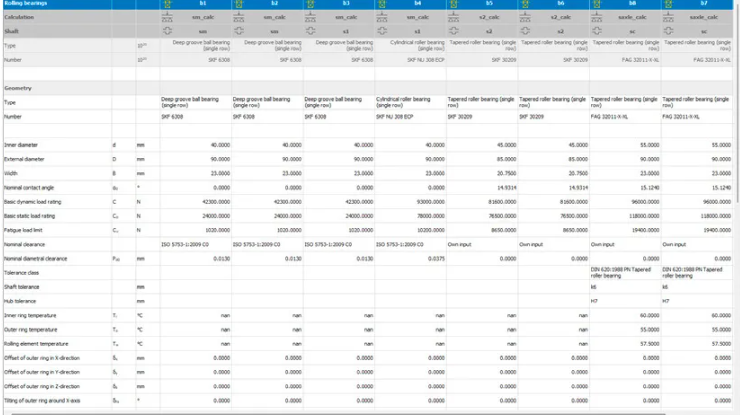

The System Module also supports the re-engineering of reference or competitor designs, facilitating improvements and optimizations of these. By re-creating in the KISSsoft System Module existing designs described through manufacturing drawings, it ensures accuracy and consistency across life cycle stages. One of its powerful features is the ability to manage and compare design variants that share the same topology, allowing engineers to evaluate different configurations efficiently, within a single System Module file.

For variants development, the System Module creates databases with various ratios tailored to different torque ranges, streamlining the design process for different gearbox sizes. Furthermore, it assists in visualizing and explaining concepts, preliminary designs, and proposals, making it easier to communicate and promote ideas within engineering teams, to stakeholders and potential buyers.

Finally, the System Module connects and manages available KISSsoft files, safeguarding these valuable component models used for individual analysis, ensuring data integrity and seamless integration of detail information elaborated by junior engineers in complex engineering projects managed by more senior staff. This approach keeps license costs as low as possible.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.