AI Robot Joint Revolution: How Bearings Became the Invisible Champions of the Smart Era

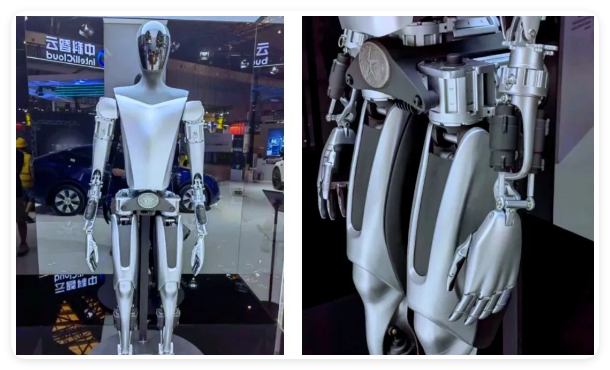

When humanoid robots like Optimus walk with agility, when surgical robots suture blood vessels with precision, and when logistics bots navigate warehouses 24/7—behind this AI-driven robotics revolution lies a rarely mentioned yet critical "invisible champion": bearings.

More than just robotic "joints," bearings are the core enablers of precision, longevity, and intelligence. As AI robotics explode into the mainstream, bearings are evolving from "mechanical supporters" to "smart cores," quietly powering a transformative technological leap.

Pushing the Limits: The Extreme Demands on AI Robot "Joints"

With AI robots penetrating industries—from manufacturing and healthcare to domestic services and education—the demand for bearings is surging exponentially. Market analysts project that the market for humanoid robot bearings will skyrocket to billions of dollars in the coming years, sustaining rapid growth.

Yet, compared to industrial robots, AI robots (e.g., humanoids, cobots) impose far stricter requirements:

Precision: Finger joint bearings must achieve errors <0.001mm (1/80th of a human hair).

Lightweighting: Boston Dynamics’ Atlas leg bearings endure 200kg impact forces at just 5g weight.

Smart Sensing: Embedded sensors provide real-time torque/temperature feedback, enabling "sense-decide-act" loops.

Ultra-Durability: Surgical robot bearings must operate flawlessly across 100,000 procedures.

The Challenge: Traditional industrial bearings—rigid, high-friction, and maintenance-heavy—fail to meet AI robotics’ needs for flexibility, intelligence, and ultra-precision.

The Game-Changers: 3 Breakthrough Bearing Technologies

1. Flexible Bearings: Giving Robots "Human-Like" Agility

Core Tech: Flexure hinges (e.g., cross-roller bearings) + superelastic materials (e.g., nitinol).

Applications:

Tesla Optimus’s 19 flexible bearings (of 28 joints) enable 0.1N grip precision.

Ottobock’s exoskeleton knee bearings mimic human ligaments, restoring natural gait for amputees.

2. Smart Bearings: Sensor-Embedded "Nervous System"

Core Tech: MEMS sensors integrated into bearing races for real-time vibration/temperature/load monitoring.

Applications:

ABB YuMi’s smart bearings predict failures, reducing downtime by 90%.

Intuitive Surgical’s Da Vinci system uses fiber-optic sensor bearings with <0.02mm error.

3. Micro-Precision Bearings: Enabling "Capillary-Level" Robotics

Core Tech: Sub-1mm ceramic hybrid bearings (silicon nitride balls + steel cages).

Applications:

Medical nanobots: Drug-delivery microbearings spin at 100,000 RPM.

DJI Mavic 3 gimbal motors use 3mm-diameter bearings with 0.005° anti-shake precision.

The Future: "Symbiotic Evolution" of Bearings and AI

Self-Learning Bearings:

AI analyzes wear data to optimize lubrication (e.g., Schaeffler’s Smart Bearing).

Boston University lab achieves 95% accuracy in bearing lifespan prediction.

3D-Printed Monolithic Bearings:

Optisys’s RF-integrated bearings cut weight by 70%, ideal for space robots.

Superconducting Magnetic Bearings:

NSK’s near-zero-friction magnetic bearings enable maintenance-free nuclear rescue robots.

As AI robotics redefine industries, bearings—once humble mechanical parts—are now the unsung heroes of intelligence, precision, and endurance. The future of robotics isn’t just about AI brains; it is about the smart joints that make movement possible.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.