The number one complaint from maintainers in the field is that they can’t get the parts they need in a timely manner. This is happening despite the inventory on store-room shelves, store personnel, inventory managers and busy purchasing departments. The established processes may be working as designed, but they are not delivering. Maintenance planners and supervisors become part chasers, tracking down components job by job and building up hidden inventories — unintentionally contributing to the very problem they are trying to solve.

Zoom out to see the problem

Manufacturing assembly lines provide a confluence of parts, processes and actions that come together in a final product — their common goal. Business processes also have a common goal, but high levels of specialization and management in silos wreak havoc on the results. A lack of cross-functional understanding, such as between maintenance and inventory management, causes communication breakdowns among people, and the business processes they manage.

Processes may be working at cross purposes. Stores and inventory management want to reduce inventory, rather than ensuring they have the right inventory. Purchasing wants the lowest pricing, yet delays often result in excessive production downtime. Maintenance wants immediate delivery and does whatever is needed to achieve it. Moreover, departmental goals can conflict with each other. For example, reducing transportation costs by only shipping full truckloads directly impacts the inventory or stores department’s bottom line and shelving space.

Zoom in to uncover the root causes

Stockouts indicate insufficient quantities often because the wrong items have been ordered. Identifying needs and demand can be problematic. Effective inventory management should forecast lead times and track trends, but this requires ERP software and diligent lead time tracking.

Shorter lead times can reduce inventory; however, lead times do not consider the purchasing process time, which often adds time as purchasing seeks small dollar savings per part. When reviewed holistically, how much was really saved when ordering a cheaper part (with a likely longer lead time, and the additional time spent looking for that cheaper part)?

Maintenance repairs are usually rushed; if an item is missing from stock when needed, planners will resort to direct purchase to expedite delivery. The PO is tracked to the WO but not necessarily against the stocked-out stores item. In stores, the higher-than-expected consumption escapes notice, demand appears lower than it really is, and it’s likely the item will be “out of stock” yet again in the future. Maintainers experience the higher level of consumption but are too busy, or don’t think to inform those responsible for inventory management. Eventually, they buy extras and stash them away in their shops.

Forecasting inventory based solely on system purchases, which ignores direct buys, leads to inaccurate results. Often, if a part is needed sooner, a planner will bypass the system and purchase it directly. While the PO is tracked to the work order, the inventory itself isn’t logged, perpetuating the cycle. Additionally, if a part isn’t in stores, it’s perceived as “out of stock” by maintainers, who then buy it directly, further bypassing the inventory system.

Ad hoc reductions in stock to eliminate non-moving parts can also remove critical spares if they’re not properly classified. Proper classification helps stores, inventory and purchasing understand substitution options, review frequencies and more.

Maintenance and engineering must be involved in demand forecasting and decisions on sourcing critical parts. Inventory classification should involve all departments.

Despite pressures from operations, maintainers must follow the business processes associated with using spares. By-passing stores through using direct purchases hides consumption (demand) data. As these items are bought through direct purchase, they are not included in consumption data, which forecasting relies on. Thus, inventory management decisions are inaccurate. This results in a vicious cycle of out of stock, wrong inventory being ordered, and the growth of squirrel stores.

Are the right jobs being done?

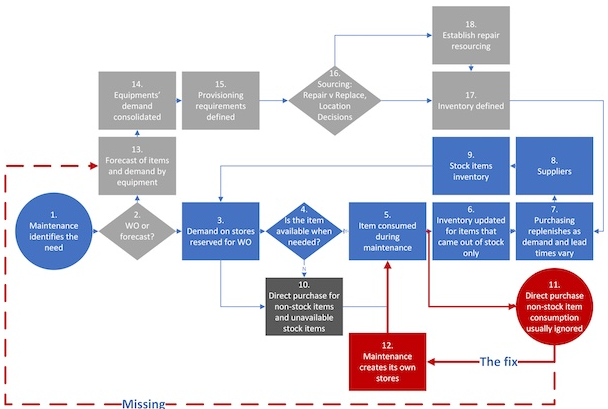

The diagram below shows what is, or should be, happening. The blue steps are often followed, whereas the grey steps are often missed, even with new projects. If all steps are followed, the “consolidation” step (#14) is often handled poorly. The solid red steps highlight the work-arounds maintenance does in order to satisfy operational needs. The dashed red line is typically missing, yet if organizations used it, the hidden maintenance stores could disappear. Missing parts translate into equipment downtime, lost revenue and avoidable workaround costs including maintenance overtime, contractors, spare part stashes, and rushed deliveries.

Are the dollars saved by procurement worth the revenue lost waiting for multiple quotes and other delays in processing orders? Are dollars saved in reducing stock levels worth the dollars hidden in those maintenance stashes, the rushed orders and the downtime that stockouts add? When viewed holistically and organizationally wide, the answer is likely, “no.”

This begs the question: Are you really getting the best use of your planners and supervisors who are chasing purchasing, expediting part deliveries and managing their own stashes of parts? Their time is better spent in planning so that trades wrench time can reach its potential.

Fixing the process shortcomings

The challenge in closing these gaps and ending the vicious cycle of stock outs is that there is no single party responsible for fixing it. Maintenance, stores, inventory and purchasing are all involved; however, due to siloing, the managers of those functions have very little understanding of the other functions. Moreover, the performance metrics of these departments require a focus on optimizing their own individual department processes, which drives overall dysfunction.

Collaboration on business process design and then changes to the configuration of management IT systems is needed, adding yet another silo. For these changes to succeed, training and education of all parties involved is required. Reliance on the IT systems alone isn’t enough, especially if the systems or processes were not designed to support an integrated process, thus not optimizing the outcome.

As each organization is unique, each case will be different. A thorough review of existing processes and how they interact is needed to create a properly integrated system. The process map provided is a good start. Ideally, an organization will gather personnel from each department together and create a Value Stream Map — a map which draws out the process while highlighting each department’s involvement in the process. While completing this map, it is fundamental to document areas or steps which are seen as pain points, just as it is important to document steps that departments feel are working. Discuss the pain points and understand the root cause.

A great way to do this is by using Lean®’s Five Why’s, or an Ishikawa diagram. First, understand the root cause of direct purchases, then design a new process to reduce the root cause of the direct purchases. Once the current process is documented, pain points understood and their root causes known, an organization can begin to create an optimized process flow. Use Value Stream Mapping to obtain feedback from all departments involved the process. A new process is not truly optimized if the pain points still exist or more have been created.

Why you can’t fix it yourself

This is not an isolated issue, so fixing it in isolation won’t create lasting change. A multi-disciplinary team is needed to resolve it. Unfortunately, most organizations are lean on staffing, limiting bandwidth to tackle complex, multi-departmental problems. However, there are actions a single department or person can take, such as understanding root causes, reviewing part lead times and ensuring accuracy — or adding lead time if none exists. Classify inventory based on demand, cost, lead time, or importance — just remember, classifying everything as “critical” renders the classification meaningless. Use this classification to create a list of critical spares and share it with sourcing, procurement, stores and inventory to ensure proper availability and storage.

Lastly, communicate with those in other departments to better understand how your department can make their lives easier. People typically respond better to “How can we make your life easier?” than they do “I need your department to change to make it easier for my department.”

Next Manufacturing Parameter Considerations and Virtual Analysis

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.