Auto industry steel project to boost efficiency, safety

Higher-strength, lighter-weight steels could be coming to a car near you in the near future as part of a U.S. Dept. of Energy (DOE) advanced manufacturing initiative. Los Alamos National Laboratory and Colorado School of Mines (CSM) researchers are lending their expertise to a three-year, $1.2-million project to develop a new class of advanced steels for the automotive industry, materials that will be produced using cleaner manufacturing methods and eliminating the traditional heat-treatment and associated costs and hazards of the process.

“The new project’s goal is to eliminate the time and energy required to heat these parts to around 900 C (red-hot) by creating steels that will meet the safety requirement and still be formable at room temperature,” said Kester Clarke, one of the Los Alamos researchers. The current method for forming safety-critical “b-pillars” for automotive applications is a process called hot-stamping.

As experts in phase transformations in steels, microstructural evolution and alloying/processing response, researchers will use specialized Los Alamos capabilities to help meet the project’s advanced manufacturing initiatives.

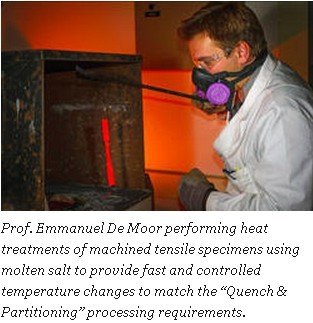

The project, “Quenching and Partitioning Process Development to Replace Hot Stamping of High Strength Automotive Steel,” is led by CSM Metallurgical and Materials Engineering Prof. Emmanuel De Moor, along with colleagues David Matlock and John Speer of the school’s Advanced Steel Processing and Products Research Center. Los Alamos National Laboratory researchers Amy Clarke (a Mines alumna), Robert Hackenberg and Kester Clarke (also a Mines graduate) are also part of the effort as well as industrial partners AK Steel, General Motors Corporation, Nucor Steel, Severstal, Toyota and United States Steel Corporation.

Specialized equipment at Los Alamos such as a quench dilatometer will be used to provide critical details about phase transformations during heating and cooling, which will, in turn, guide the development of steel compositions and thermal processing routes. Advanced microstructure characterization techniques, including electron microscopy, neutron diffraction and bulk thermal- and deformation-processing capabilities will be used to simulate industrial-scale processing.

The project is part of a DOE $23.5 million investment in innovative manufacturing R&D projects.

Higher-strength, lighter-weight steels could be coming to a car near you in the near future as part of a U.S. Dept. of Energy (DOE) advanced manufacturing initiative. Los Alamos National Laboratory and Colorado School of Mines (CSM) researchers are lending their expertise to a three-year, $1.2-million project to develop a new class of advanced steels for the automotive industry, materials that will be produced using cleaner manufacturing methods and eliminating the traditional heat-treatment and associated costs and hazards of the process.

“The new project’s goal is to eliminate the time and energy required to heat these parts to around 900 C (red-hot) by creating steels that will meet the safety requirement and still be formable at room temperature,” said Kester Clarke, one of the Los Alamos researchers. The current method for forming safety-critical “b-pillars” for automotive applications is a process called hot-stamping.

As experts in phase transformations in steels, microstructural evolution and alloying/processing response, researchers will use specialized Los Alamos capabilities to help meet the project’s advanced manufacturing initiatives.

The project, “Quenching and Partitioning Process Development to Replace Hot Stamping of High Strength Automotive Steel,” is led by CSM Metallurgical and Materials Engineering Prof. Emmanuel De Moor, along with colleagues David Matlock and John Speer of the school’s Advanced Steel Processing and Products Research Center. Los Alamos National Laboratory researchers Amy Clarke (a Mines alumna), Robert Hackenberg and Kester Clarke (also a Mines graduate) are also part of the effort as well as industrial partners AK Steel, General Motors Corporation, Nucor Steel, Severstal, Toyota and United States Steel Corporation.

Specialized equipment at Los Alamos such as a quench dilatometer will be used to provide critical details about phase transformations during heating and cooling, which will, in turn, guide the development of steel compositions and thermal processing routes. Advanced microstructure characterization techniques, including electron microscopy, neutron diffraction and bulk thermal- and deformation-processing capabilities will be used to simulate industrial-scale processing.

The project is part of a DOE $23.5 million investment in innovative manufacturing R&D projects.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Wind Turbine Maker Shuttering Arkansas Factory

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.