FAG split spherical roller bearings – simple and quick to mount

Resource from: Schaeffler Technologies AG & Co. KG Likes:472

Jul 15,2013

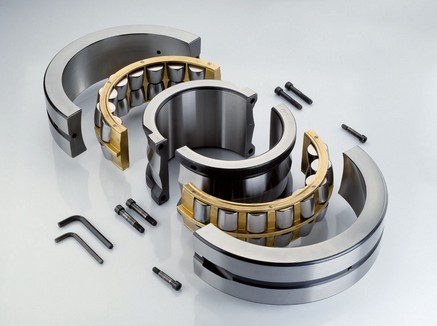

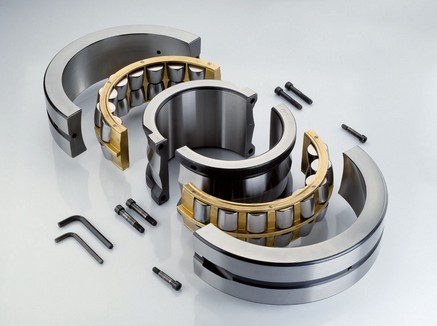

FAG split spherical roller bearings simplify and speed up bearing replacement, particularly in areas that are difficult to access such as shafts with multiple supports. In a split bearing, the inner ring, the outer ring, and the roller and cage assembly are divided into two halves that are clamped together with screws. Using the split version of these bearings allows numerous process steps to be omitted during mounting and dismounting. This means that downtimes can be significantly reduced and correspondingly high cost savings can be achieved. Because the dimensions have been exactly matched, the split spherical roller bearings can be installed in the same space as their unsplit counterparts (including the adapter sleeve). Applications include belt drives, paper machines, ships, conveying equipment, converters, rolling mills, and ventilation-related systems.

Splitting means improvement

In many applications, the spherical roller bearing is mounted on the shaft in such a complex fashion that it is also necessary to remove all the adjacent components in order for it to be replaced. This leads to long downtimes and complex additional tasks such as the removal of gears, clutches, and drive units. Extra costs are also incurred for additional replacement parts, tools, personnel, and even crane rental. When the split bearing version is used, most of these process steps are no longer required and the associated additional costs no longer arise. Mounting and dismounting can be carried out significantly faster and are simplified, especially in bearing positions that are difficult to access. Schaeffler offers split spherical roller bearings for shaft diameters ranging from 55 mm to 630 mm. In most cases, the outside diameter, the outer ring width, and the diameter of the shaft seat match the dimensions of the standard spherical roller bearings, including the adapter sleeve, so the bearings are interchangeable without any problems.

Application example: Installation of a split spherical roller bearing on the exhaust gas fan of a chemical plant

The spherical roller bearing in the exhaust gas fan of a chemical plant, which had an outside diameter of 230 mm, was in need of replacement. In the past, this application employed unsplit bearings that caused a downtime of 14 hours and generated costs of approximately 280,000 euros every time a bearing replacement was carried out. In addition to the immense outlay for the production stoppage, this included the costs for personnel, additional outlay for the alignment of the shaft, crane rental, and a further replacement bearing. With the FAG split spherical roller bearing, the downtime was only three hours and the overall costs 60,000 euros. The additional alignment, the crane rental, and the further replacement bearing were not required. The customer saved around 220,000 euros by using the split bearing.

The inner ring, outer ring, and roller and cage assembly of FAG split spherical roller bearings are divided into two halves.

The inner ring, outer ring, and roller and cage assembly of FAG split spherical roller bearings are divided into two halves.

The split version simplifies and speeds up bearing mounting, especially at installation points that are difficult to access.

The split version simplifies and speeds up bearing mounting, especially at installation points that are difficult to access.

(Schaeffler Technologies AG & Co. KG)

【CBCC News Statement】

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.

The inner ring, outer ring, and roller and cage assembly of FAG split spherical roller bearings are divided into two halves.

The inner ring, outer ring, and roller and cage assembly of FAG split spherical roller bearings are divided into two halves.

The split version simplifies and speeds up bearing mounting, especially at installation points that are difficult to access.

The split version simplifies and speeds up bearing mounting, especially at installation points that are difficult to access.