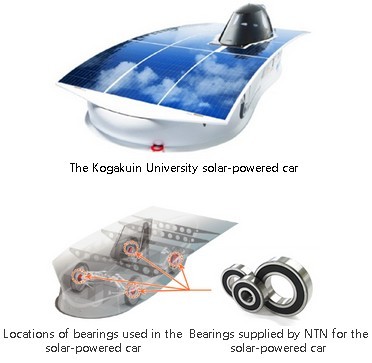

NTN to Supply Specially-designed Bearings for the Kogakuin University Car Participating in the "World Solar Challenge"

Resource from: NTN Corporation Likes:381

Jul 29,2013

NTN Corporation (hereafter, NTN) will supply specially-designed bearings for the Kogakuin University car participating in the “World Solar Challenge” international solar-powered car race to be held in Australia in October this year.

NTN has increased its interaction with the Kogakuin University's Faculty of Engineering, Department of Mechanical Engineering through the Tribology Workshop, and has developed bearings for motors and axles as part of support for student “monozukuri” activities for Kogakuin University, which will be participating in the challenge for the first time.

The “World Solar Challenge” is one of the largest solar-powered car races in the world, where participants race against the clock over 3,021 km through the desert between Darwin and Adelaide in Australia, using the sun as the only source of power. With a 20-year history dating from its beginnings in 1987, the race attracts participants from around the world, including many universities and corporations. Kogakuin University is aiming to win its first podium finish in the race.

Solar-powered cars are electric vehicles that convert energy from the sun to electrical energy in order to drive electrical motors and turn the tires. A structural design with minimal electric loss is required to drive long distances using electrical energy obtained only from the solar cells.

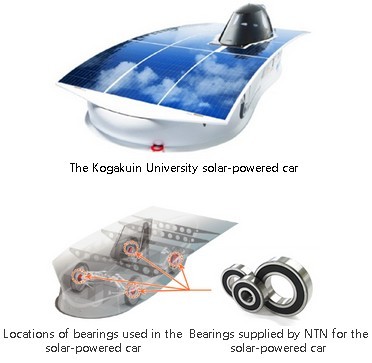

The deep groove ball bearing developed by NTN for the challenge offers JIS 5 class, which is two grades higher than the general JIS 0 class, to help improve turning precision. Steel balls have been changed to ceramic balls and the curvature of the rolling contact surface has been optimized in order to reduce the contact area and achieve a lower torque, while a low-viscosity grease with minimal agitation resistance has been used. These help to reduce rotational torque by 50% compared to conventional products. The steel shield has been changed to a non-contact rubber seal to improve resistance against penetration of foreign matter in preparation for driving through desert areas.

In addition to drive wheel motors, NTN bearings are used in driven wheel axle shafts to reduce rotational torque. This helps to deliver a high speed with minimal consumption of electrical energy, and also contributes to longer distance driving.

(NTN Corporation)

【CBCC News Statement】

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.