Schaeffler introduces customized drive and transmission solutions: Plug-in drives

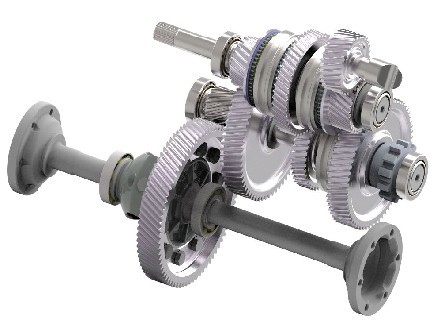

Plug-in hybrid vehicles combine the best of both worlds: Octane and amperes. That is why they are becoming more and more established, and Schaeffler offers customized drive and transmission solutions for these cars that are equipped with both internal combustion engines and electric motors – whether for sporty vehicles or those driven mainly in cities. Among the worldwide firsts at the 2014 Schaeffler Symposium are a drive integrated into the transmission with power splitting and a range extender transmission. The latter is a three-speed transmission with an integrated electric motor, which can be combined with internal combustion engines. "This clever and cost-effectively designed transmission facilitates all-electric driving in everyday use and the best possible use of the electric and conventional drive”, explains Norbert Indlekofer, CEO Automotive at Schaeffler. “At the same time, we can allay any drivers' anxiety about being stuck with a flat battery.”

Plug-in hybrid vehicles are designed in such a way that they can drive distances of 20 to 50 kilometers and at speeds of up to 120 km/h using only electric power. The internal combustion engine comes into play when lengthier interurban journeys and higher speeds are necessary. The term “plug-in” means that these hybrid vehicles can be “refueled” at a power socket or charging column. Their nominal CO2 emission values are therefore very low. “Almost all automobile manufacturers rely on plug-in hybrids”, says Schaeffler’s Chief Technology Officer Prof. Peter Gutzmer. “Large and high-performance vehicles in particular will be equipped with plug-in technology in the future”.

For the engineers at Schaeffler, this means that future hybrid drives will have to generate higher levels of power and torque. They must also be able to transfer these without taking up any additional space in the vehicle. Normally, the electric drive is mounted in the place of the torque converter between the internal combustion engine and the automatic transmission. The latest generation of the Schaeffler hybrid module does an even better job in the tight space available here than its predecessor, which was produced in 2010. And it can also be used in double clutch transmissions. The integration of the disconnect clutch into the rotor of the electric motor saves installation space. The clutch transfers torques of up to 300 Nm from the internal combustion engine, but the use of a one-way clutch allows significantly higher torques to be transferred directly to the transmission input shaft – i.e. by bypassing the clutch. Depending on its design, the new hybrid module is therefore also suitable for very sporty vehicles with engine torques of up to 800 Nm. The electric motor - a permanently excited synchronous motor with a high proportion of reluctance – generates up to 100 kW of power.

Furthermore, the engineers at Schaeffler want to use the electric motor to reduce torsional vibrations in the powertrain. Every internal combustion engine generates vibrations, and this applies particularly to engines with a low number of cylinders. These vibrations, which are caused by rotational irregularities, can be damped by means of dual mass flywheels and centrifugal pendulum-type absorbers, for example. They can also be effectively reduced through targeted variation of the electric motor’s speed, however.

Together with the range extender transmission, Schaeffler is additionally presenting the results of an internal advance development project at the Symposium. The electric motor variant displayed by Schaeffler can directly drive the front axle by way of a simple three-speed transmission. The vehicle is thus started using electric power and, when the battery is charged, drives through urban areas using electric power at all times. In addition, however, the internal combustion engine can also be used to directly drive the axles mechanically, which is ideal for application at higher speeds due to its higher overall efficiency. The internal combustion engine is also used for acceleration outside built-up areas and for charging the battery.

Schaeffler also offers products for automobile manufacturers who would like to extend their existing range of powertrains based on internal combustion engines by offering a plug-in variant, for example, with an electric axle, which is specifically designed for the requirements of plug-in hybrids. A two-speed transmission is part of this drive element. The 65-kilowatt electric motor has a significantly increased power density. The weight of the drive unit has been reduced by 41 kilograms compared to the variant in the Schaeffler ACTIVeDRIVE concept vehicle presented in 2011, and is now just 79 kilograms. The electric axle can also be optionally equipped with a torque vectoring function, significantly increasing vehicle agility.

As regulations governing emissions become more and more stringent worldwide and as the introduction of new CO2 limits throughout Europe in 2020/2021 draws nearer, plug-in hybrids will also become increasingly widespread in the upper vehicle classes. Schaeffler has created the basis it needs to help shape this trend thanks to its innovative products.

Plug-in hybrid vehicles combine the best of both worlds: Octane and amperes. That is why they are becoming more and more established, and Schaeffler offers customized drive and transmission solutions for these cars that are equipped with both internal combustion engines and electric motors – whether for sporty vehicles or those driven mainly in cities. Among the worldwide firsts at the 2014 Schaeffler Symposium are a drive integrated into the transmission with power splitting and a range extender transmission. The latter is a three-speed transmission with an integrated electric motor, which can be combined with internal combustion engines. "This clever and cost-effectively designed transmission facilitates all-electric driving in everyday use and the best possible use of the electric and conventional drive”, explains Norbert Indlekofer, CEO Automotive at Schaeffler. “At the same time, we can allay any drivers' anxiety about being stuck with a flat battery.”

Plug-in hybrid vehicles are designed in such a way that they can drive distances of 20 to 50 kilometers and at speeds of up to 120 km/h using only electric power. The internal combustion engine comes into play when lengthier interurban journeys and higher speeds are necessary. The term “plug-in” means that these hybrid vehicles can be “refueled” at a power socket or charging column. Their nominal CO2 emission values are therefore very low. “Almost all automobile manufacturers rely on plug-in hybrids”, says Schaeffler’s Chief Technology Officer Prof. Peter Gutzmer. “Large and high-performance vehicles in particular will be equipped with plug-in technology in the future”.

For the engineers at Schaeffler, this means that future hybrid drives will have to generate higher levels of power and torque. They must also be able to transfer these without taking up any additional space in the vehicle. Normally, the electric drive is mounted in the place of the torque converter between the internal combustion engine and the automatic transmission. The latest generation of the Schaeffler hybrid module does an even better job in the tight space available here than its predecessor, which was produced in 2010. And it can also be used in double clutch transmissions. The integration of the disconnect clutch into the rotor of the electric motor saves installation space. The clutch transfers torques of up to 300 Nm from the internal combustion engine, but the use of a one-way clutch allows significantly higher torques to be transferred directly to the transmission input shaft – i.e. by bypassing the clutch. Depending on its design, the new hybrid module is therefore also suitable for very sporty vehicles with engine torques of up to 800 Nm. The electric motor - a permanently excited synchronous motor with a high proportion of reluctance – generates up to 100 kW of power.

Furthermore, the engineers at Schaeffler want to use the electric motor to reduce torsional vibrations in the powertrain. Every internal combustion engine generates vibrations, and this applies particularly to engines with a low number of cylinders. These vibrations, which are caused by rotational irregularities, can be damped by means of dual mass flywheels and centrifugal pendulum-type absorbers, for example. They can also be effectively reduced through targeted variation of the electric motor’s speed, however.

Together with the range extender transmission, Schaeffler is additionally presenting the results of an internal advance development project at the Symposium. The electric motor variant displayed by Schaeffler can directly drive the front axle by way of a simple three-speed transmission. The vehicle is thus started using electric power and, when the battery is charged, drives through urban areas using electric power at all times. In addition, however, the internal combustion engine can also be used to directly drive the axles mechanically, which is ideal for application at higher speeds due to its higher overall efficiency. The internal combustion engine is also used for acceleration outside built-up areas and for charging the battery.

Schaeffler also offers products for automobile manufacturers who would like to extend their existing range of powertrains based on internal combustion engines by offering a plug-in variant, for example, with an electric axle, which is specifically designed for the requirements of plug-in hybrids. A two-speed transmission is part of this drive element. The 65-kilowatt electric motor has a significantly increased power density. The weight of the drive unit has been reduced by 41 kilograms compared to the variant in the Schaeffler ACTIVeDRIVE concept vehicle presented in 2011, and is now just 79 kilograms. The electric axle can also be optionally equipped with a torque vectoring function, significantly increasing vehicle agility.

As regulations governing emissions become more and more stringent worldwide and as the introduction of new CO2 limits throughout Europe in 2020/2021 draws nearer, plug-in hybrids will also become increasingly widespread in the upper vehicle classes. Schaeffler has created the basis it needs to help shape this trend thanks to its innovative products.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next NSK Releases Cost Saving Calculator App for Tablets, Smart Phones and PC

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.