Schaeffler introduces new robust, high accuracy, integrated travel measurement system for machine tools

In machine tools and other production machinery, in order to accurately move, control and position tools and workpieces, it is necessary to determine travel distances and changes in travel or position. Travel measurement systems in combination with linear guidance systems are often used for this purpose. If these measurement systems can be integrated into the guidance system, both functions – guidance and measurement – can be matched to each other for optimum performance.

Precision bearing manufacturer Schaeffler has developed an integrated measuring system for travel measurements in the main axes of machine tools and other high precision production machinery.

The LMSA (length measurement system analogue) series from Schaeffler uses an inductive analogue measuring principle to achieve a high accuracy of +/- 3µm/m. The system is characterised by its high robustness and insensitivity to electromagnetic interference. The system also operates without hysteresis, i.e. without any magnetism or residual magnetism.

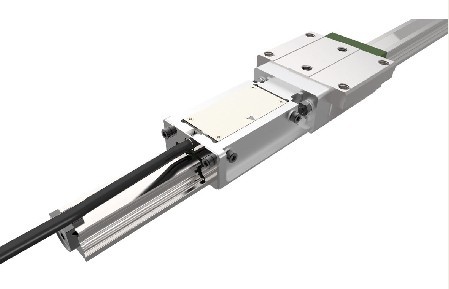

Similar to the LMST and LMSD series of integrated measurement systems from Schaeffler, the new KUVE..LMSA series of fully integrated measuring system and linear recirculating ball bearing and guideway assembly, comprises a carriage with an adaptable housing for the measuring head and a guideway to accommodate the measuring scale.

Measurements are carried out according to the inductive principle (similar to a transformer) with a moveable reluctance core. A planar coil structure in the sensor head scans the incremental measuring scale in the head of the guideway using a high-frequency alternating field and generates two sensor signals with a 90° phase offset. A high-grade steel strip with a photo-lithographically-etched high precision scale forms the dimensional measuring scale. The movement between the sensor head and the measuring strip generates a mutual inductance in the individual coils and therefore generates sine wave signals. This means the LMSA measurement system has an analogue output of 1 Vss with sub-divided signal periods of up to 10 µm. This allows the measurement system to be easily integrated to existing control systems.

A precise, minimum distance must be maintained between the measuring head on the carriage and the measuring scale in the guideway. In order to ensure a high accuracy of +/- 3µm/m, the dimensional scale is therefore integrated in a special three-layer measuring strip. This strip comprises a backing strip, the actual dimensional measuring scale and a cover strip.

The backing strip supports the individual layers, maintains an exact distance to the measuring head and provides the necessary robustness. The dimensional measuring scale is applied to the backing strip under tension to ensure high accuracy measurements. The thin hard cover strip is used to protect the surface.

The three-layer measuring strip has an adhesive strip on its underside for easy handling and mounting. The sensor head is protected inside a metal housing, which is directly connected to the steel saddle plate of the carriage. The exact distance between the measuring head and the measuring strip is factory calibrated. However, the housing is designed so that the sensor head distance can be reset if required using just four adjustable screws.

For more information on the LMSA series of integrated travel measurement systems, please call Schaeffler UK’s Marketing Department on 0121 313 5870. Alternatively, email info.uk@schaeffler.com.

In machine tools and other production machinery, in order to accurately move, control and position tools and workpieces, it is necessary to determine travel distances and changes in travel or position. Travel measurement systems in combination with linear guidance systems are often used for this purpose. If these measurement systems can be integrated into the guidance system, both functions – guidance and measurement – can be matched to each other for optimum performance.

Precision bearing manufacturer Schaeffler has developed an integrated measuring system for travel measurements in the main axes of machine tools and other high precision production machinery.

The LMSA (length measurement system analogue) series from Schaeffler uses an inductive analogue measuring principle to achieve a high accuracy of +/- 3µm/m. The system is characterised by its high robustness and insensitivity to electromagnetic interference. The system also operates without hysteresis, i.e. without any magnetism or residual magnetism.

Similar to the LMST and LMSD series of integrated measurement systems from Schaeffler, the new KUVE..LMSA series of fully integrated measuring system and linear recirculating ball bearing and guideway assembly, comprises a carriage with an adaptable housing for the measuring head and a guideway to accommodate the measuring scale.

Measurements are carried out according to the inductive principle (similar to a transformer) with a moveable reluctance core. A planar coil structure in the sensor head scans the incremental measuring scale in the head of the guideway using a high-frequency alternating field and generates two sensor signals with a 90° phase offset. A high-grade steel strip with a photo-lithographically-etched high precision scale forms the dimensional measuring scale. The movement between the sensor head and the measuring strip generates a mutual inductance in the individual coils and therefore generates sine wave signals. This means the LMSA measurement system has an analogue output of 1 Vss with sub-divided signal periods of up to 10 µm. This allows the measurement system to be easily integrated to existing control systems.

A precise, minimum distance must be maintained between the measuring head on the carriage and the measuring scale in the guideway. In order to ensure a high accuracy of +/- 3µm/m, the dimensional scale is therefore integrated in a special three-layer measuring strip. This strip comprises a backing strip, the actual dimensional measuring scale and a cover strip.

The backing strip supports the individual layers, maintains an exact distance to the measuring head and provides the necessary robustness. The dimensional measuring scale is applied to the backing strip under tension to ensure high accuracy measurements. The thin hard cover strip is used to protect the surface.

The three-layer measuring strip has an adhesive strip on its underside for easy handling and mounting. The sensor head is protected inside a metal housing, which is directly connected to the steel saddle plate of the carriage. The exact distance between the measuring head and the measuring strip is factory calibrated. However, the housing is designed so that the sensor head distance can be reset if required using just four adjustable screws.

For more information on the LMSA series of integrated travel measurement systems, please call Schaeffler UK’s Marketing Department on 0121 313 5870. Alternatively, email info.uk@schaeffler.com.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next SKF @ptitude Connect offers cost-effective cloud-based monitoring

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.