Winergy offers more options for maintenance and service of wind-turbine gearboxes

On a gearbox exhibited on the Winergy stand, the company will also show how to replace the intermediate shaft of the cylindrical gear stage on a turbine.

On a gearbox exhibited on the Winergy stand at Husum, the company will also show how to replace the intermediate shaft of the cylindrical gear stage on a turbine.

With the aid of specifically designed fixtures it is possible to move the gearbox in the nacelle and thus, the bearing can be removed. The procedure has been successfully tested on the first gearbox on a customer’s turbine and others are to follow. “It cuts the expenses for the operator of the wind turbine and shortens the downtime of the plant. It also contributes to further reducing the cost of generating energy. This is a requirement central to ensuring the economic sustainability of the wind energy of tomorrow”, says Cüneyt Uzkan, head of the Winergy Service.

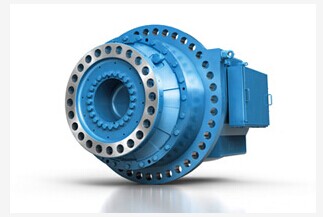

At the Husum Wind, Winergy will present the new feature in a 3D animation. On a gearbox exhibited on the Winergy stand it is also shown how to replace the intermediate shaft of the cylindrical gear stage on a turbine. The gearbox is opened with a fixture and the service technician can work in the room inside without difficulty to remove the shaft. The replacement procedure on the turbine is significantly shortened, resulting in shorter downtime of the plant.

The gearbox weighs almost 20 tons making it one of the biggest and heaviest exhibits at the fair. These are only two of several maintenance and service operations the Winergy service experts can carry out in the turbine nacelle. “We are the only company providing service and spare parts in original equipment manufacturer quality for our own gearboxes and those of other manufacturers”, Uzkan continues.

Another program by which Winergy increases the availability of wind turbines is its gearbox exchange pool. In the case of a gearbox failure, there are replacements available for all common types. So it is possible to replace the defective gearbox in no time and minimize the downtime of the turbine.

The company offers gearboxes, HybridDrives, couplings, and services to wind turbine manufacturers and wind park operators. The product portfolio covers a power range between 750 kW and 8 MW as well as a special service portfolios. Manufacturing and service locations are in Europe, China, India, and the USA and are continuously expanded worldwide by new service partners.

On a gearbox exhibited on the Winergy stand, the company will also show how to replace the intermediate shaft of the cylindrical gear stage on a turbine.

On a gearbox exhibited on the Winergy stand at Husum, the company will also show how to replace the intermediate shaft of the cylindrical gear stage on a turbine.

With the aid of specifically designed fixtures it is possible to move the gearbox in the nacelle and thus, the bearing can be removed. The procedure has been successfully tested on the first gearbox on a customer’s turbine and others are to follow. “It cuts the expenses for the operator of the wind turbine and shortens the downtime of the plant. It also contributes to further reducing the cost of generating energy. This is a requirement central to ensuring the economic sustainability of the wind energy of tomorrow”, says Cüneyt Uzkan, head of the Winergy Service.

At the Husum Wind, Winergy will present the new feature in a 3D animation. On a gearbox exhibited on the Winergy stand it is also shown how to replace the intermediate shaft of the cylindrical gear stage on a turbine. The gearbox is opened with a fixture and the service technician can work in the room inside without difficulty to remove the shaft. The replacement procedure on the turbine is significantly shortened, resulting in shorter downtime of the plant.

The gearbox weighs almost 20 tons making it one of the biggest and heaviest exhibits at the fair. These are only two of several maintenance and service operations the Winergy service experts can carry out in the turbine nacelle. “We are the only company providing service and spare parts in original equipment manufacturer quality for our own gearboxes and those of other manufacturers”, Uzkan continues.

Another program by which Winergy increases the availability of wind turbines is its gearbox exchange pool. In the case of a gearbox failure, there are replacements available for all common types. So it is possible to replace the defective gearbox in no time and minimize the downtime of the turbine.

The company offers gearboxes, HybridDrives, couplings, and services to wind turbine manufacturers and wind park operators. The product portfolio covers a power range between 750 kW and 8 MW as well as a special service portfolios. Manufacturing and service locations are in Europe, China, India, and the USA and are continuously expanded worldwide by new service partners.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Compact and precise with high performance – One-Way Clutches for E-Bikes

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.