HYTORC’s bolting products demonstrated at Power-Gen

The jGUN is an air-powered torque multiplier available in both dual speed and single speed varieties.

jGUN

The jGUN is an air-powered torque multiplier available in both dual speed and single speed varieties. Both have adjustable torque outputs and provide an even and accurate bolt load every time. When used with the HYTORC Washer, the jGUN provides the highest bolt load accuracy of any comparable bolting system. With hundreds of custom reaction fixtures available, these tools have the flexibility to adapt for any application.

The dual speed guns add a high-speed rundown mode that eliminates the need for impact guns, which are traditionally used for pre-torquing. Impact guns function by shocking the nut with fast blows by a hammer-like device. This leads to inaccuracies, heavy vibration and loud operating volume. The jGUN uses precision gearing to produce constant, calibrated power without the noise or vibration – A first in the industry!

The jGUN is an air-powered torque multiplier available in both dual speed and single speed varieties.

jGUN

The jGUN is an air-powered torque multiplier available in both dual speed and single speed varieties. Both have adjustable torque outputs and provide an even and accurate bolt load every time. When used with the HYTORC Washer, the jGUN provides the highest bolt load accuracy of any comparable bolting system. With hundreds of custom reaction fixtures available, these tools have the flexibility to adapt for any application.

The dual speed guns add a high-speed rundown mode that eliminates the need for impact guns, which are traditionally used for pre-torquing. Impact guns function by shocking the nut with fast blows by a hammer-like device. This leads to inaccuracies, heavy vibration and loud operating volume. The jGUN uses precision gearing to produce constant, calibrated power without the noise or vibration – A first in the industry!

This patented system is calibrated to achieve and maintain the required bolt load every time.

The HYTORC Nut

The HYTORC Nut is the only fastener that adds safety, speed and accuracy to any bolting job. It’s perfect for all critical applications or those set into a pocket or a counter bore situation that poses a problem with conventional tooling. This patented system is calibrated to achieve and maintain the desired bolt load every time. It can be operated hands-free, even on inverted applications. Additionally, this system eliminates the risk of damaging bolt threads – even during removal after long durations at high temperature.

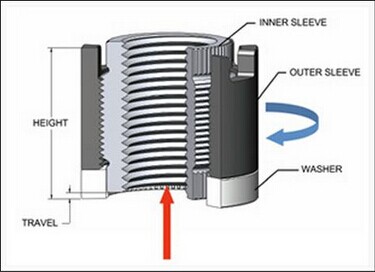

Unlike traditional fasteners, the HYTORC Nut does not turn on the bolt threads. This three-piece system uses a washer, an inner sleeve and an outer sleeve to eliminate unknown variations in friction and provide a straight pulling force on the bolt, which is locked in place when the desired load is reached. Unlike hydraulic puller-style tensioners, the HYTORC Nut never goes beyond desired load, eliminating the chance for bolt yielding and reducing operating pressure by 66 percent. The HYTORC Nut is available in all materials and sizes for use on standard or high temperature applications.

HYTORC Washer

This patented system is calibrated to achieve and maintain the required bolt load every time.

The HYTORC Nut

The HYTORC Nut is the only fastener that adds safety, speed and accuracy to any bolting job. It’s perfect for all critical applications or those set into a pocket or a counter bore situation that poses a problem with conventional tooling. This patented system is calibrated to achieve and maintain the desired bolt load every time. It can be operated hands-free, even on inverted applications. Additionally, this system eliminates the risk of damaging bolt threads – even during removal after long durations at high temperature.

Unlike traditional fasteners, the HYTORC Nut does not turn on the bolt threads. This three-piece system uses a washer, an inner sleeve and an outer sleeve to eliminate unknown variations in friction and provide a straight pulling force on the bolt, which is locked in place when the desired load is reached. Unlike hydraulic puller-style tensioners, the HYTORC Nut never goes beyond desired load, eliminating the chance for bolt yielding and reducing operating pressure by 66 percent. The HYTORC Nut is available in all materials and sizes for use on standard or high temperature applications.

HYTORC Washer

The HYTORC Washer is the simplest way to add efficiency on all bolting jobs while increasing the lifespan of tools.

The HYTORC Washer is the simplest way to add efficiency on all bolting jobs while increasing the lifespan of tools. At nearly the same cost of a standard washer, the HYTORC Washer changes everything about industrial bolting. In the past, all bolting systems required reaction fixtures to stop the tool from turning; these fixtures created dangerous pinch points and added complexity to bolting jobs. The HYTORC washer eliminates reaction fixtures, making industrial bolting safer, faster and more intuitive. Additionally, this system prevents unintentional nut loosening and ensures even and accurate bolt load every time. Using the HYTORC Washer also removes internal pressure from hydraulic torque wrenches, which increases the lifetime of the tooling.

HYTORC will be at booth 5816 at POWER-GEN International Dec. 8 to 10 at the Las Vegas Convention Center.

The HYTORC Washer is the simplest way to add efficiency on all bolting jobs while increasing the lifespan of tools.

The HYTORC Washer is the simplest way to add efficiency on all bolting jobs while increasing the lifespan of tools. At nearly the same cost of a standard washer, the HYTORC Washer changes everything about industrial bolting. In the past, all bolting systems required reaction fixtures to stop the tool from turning; these fixtures created dangerous pinch points and added complexity to bolting jobs. The HYTORC washer eliminates reaction fixtures, making industrial bolting safer, faster and more intuitive. Additionally, this system prevents unintentional nut loosening and ensures even and accurate bolt load every time. Using the HYTORC Washer also removes internal pressure from hydraulic torque wrenches, which increases the lifetime of the tooling.

HYTORC will be at booth 5816 at POWER-GEN International Dec. 8 to 10 at the Las Vegas Convention Center.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next TechnoCentre éolien selected to optimize production of Senvion wind turbines in icing conditions

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.