ETEL Introduces the New XYZ3TH Motion System With VULCANO XY

ETEL is pleased to announce its new XYZ3TH Stacked System as entering the already broad range of ETEL motion systems. The VULCANO XY part of it is a three-piece-design stacked system results in a cost-engineered solution providing high dynamics, great bidirectional repeatability, and outstanding position stability. It was born as a semiconductor front-end solution but can also serve many other applications.

The XY system is a mechanical bearing-based platform, integrating iron core linear motors, and mainly dedicated to point-to-point applications. The bottom axis is composed of two linear motors controlled in a gantry mode moving on three decoupled linear bearings. The upper linear motor lays on a stiff and light baseplate allowing travels larger than 650 mm. The stage is easily configurable and can be outfitted with the module (theta, ZTheta, ZThetaTip Tilt) best suited to each individual application. Thanks to the flexibility of the platform, it is perfectly suited for front-end segment with wafer process control applications such as Overlay metrology, Critical Dimension and Thin Film Metrology, as well as back-end applications with advanced packaging related ones, to name but a few.

The mechanical bearings provide high stiffness in the XY plane as well as in the vertical direction, allowing for high accelerations (up to 2.5 g), high speed (up to 2 m/s), great bidirectional repeatability (±250 nm for the X and Y axes) and position stability in the nanometer range.

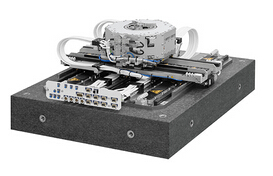

The image shows an XYZ3TH configuration mounting an ETEL Z3TH Combined Module on the upper axis of the XY assembly. The Z3TH Combined Module provides 364° Theta rotation, double Z-axes, a coarse one for wafer loading and unloading, and a fine one for focus adjustment, as well as a Tip and Tilt correction over ±0.1°. This Z3TH module is a nice alternative to piezo based Z actuators, eliminating the hysteresis and non-linearity in open loop while offering better tracking error during movement, repeatability, and move and settle performance yet over much longer travels.

This module can be replaced to best suit the needs of an application, whether that application requires only Z motion, pure Theta motion, or ZT motion without Tip and Tilt correction. The stroke of the X and Y axes can be adjusted to accommodate a 300mm or 450mm wafer, and to cope with the needs of even longer strokes for panel-based applications. The platform can also be integrated with ETEL’s QuiET Active Isolation System to further improve system performance.

The advantages offered by the ETEL XYZ3TH Stacked System include, but are not limited to, the following:

Low move and settle times (25 mm ±100 nm in less than 130 ms) @tool point

High dynamics, 25 m/s2 acceleration and 2 m/s speed

Tip and tilt correction over ±0.1° for leveling and for move and settle improvement

Vacuum feed-through to the chuck level

Double Z integration: coarse travel for loading/unloading and fine travel for focus adjustment

Compact footprint

ISO class 1 clean room compatibility

Position stability of ±1nm for X and Y axes, ±1nm for Z axis, and ±1 nm @ 150 mm radius for T axis

Low radial axial and radial runout of ±1 μm

Bidirectional repeatability of ±250 nm for X and Y axes, ±15 nm over 100 μm for Z axis, and ±0.36 arc sec for T axis

ETEL is pleased to announce its new XYZ3TH Stacked System as entering the already broad range of ETEL motion systems. The VULCANO XY part of it is a three-piece-design stacked system results in a cost-engineered solution providing high dynamics, great bidirectional repeatability, and outstanding position stability. It was born as a semiconductor front-end solution but can also serve many other applications.

The XY system is a mechanical bearing-based platform, integrating iron core linear motors, and mainly dedicated to point-to-point applications. The bottom axis is composed of two linear motors controlled in a gantry mode moving on three decoupled linear bearings. The upper linear motor lays on a stiff and light baseplate allowing travels larger than 650 mm. The stage is easily configurable and can be outfitted with the module (theta, ZTheta, ZThetaTip Tilt) best suited to each individual application. Thanks to the flexibility of the platform, it is perfectly suited for front-end segment with wafer process control applications such as Overlay metrology, Critical Dimension and Thin Film Metrology, as well as back-end applications with advanced packaging related ones, to name but a few.

The mechanical bearings provide high stiffness in the XY plane as well as in the vertical direction, allowing for high accelerations (up to 2.5 g), high speed (up to 2 m/s), great bidirectional repeatability (±250 nm for the X and Y axes) and position stability in the nanometer range.

The image shows an XYZ3TH configuration mounting an ETEL Z3TH Combined Module on the upper axis of the XY assembly. The Z3TH Combined Module provides 364° Theta rotation, double Z-axes, a coarse one for wafer loading and unloading, and a fine one for focus adjustment, as well as a Tip and Tilt correction over ±0.1°. This Z3TH module is a nice alternative to piezo based Z actuators, eliminating the hysteresis and non-linearity in open loop while offering better tracking error during movement, repeatability, and move and settle performance yet over much longer travels.

This module can be replaced to best suit the needs of an application, whether that application requires only Z motion, pure Theta motion, or ZT motion without Tip and Tilt correction. The stroke of the X and Y axes can be adjusted to accommodate a 300mm or 450mm wafer, and to cope with the needs of even longer strokes for panel-based applications. The platform can also be integrated with ETEL’s QuiET Active Isolation System to further improve system performance.

The advantages offered by the ETEL XYZ3TH Stacked System include, but are not limited to, the following:

Low move and settle times (25 mm ±100 nm in less than 130 ms) @tool point

High dynamics, 25 m/s2 acceleration and 2 m/s speed

Tip and tilt correction over ±0.1° for leveling and for move and settle improvement

Vacuum feed-through to the chuck level

Double Z integration: coarse travel for loading/unloading and fine travel for focus adjustment

Compact footprint

ISO class 1 clean room compatibility

Position stability of ±1nm for X and Y axes, ±1nm for Z axis, and ±1 nm @ 150 mm radius for T axis

Low radial axial and radial runout of ±1 μm

Bidirectional repeatability of ±250 nm for X and Y axes, ±15 nm over 100 μm for Z axis, and ±0.36 arc sec for T axis

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Saint-Gobain Performance Plastics L+S GmbH Exhibits at CTI USA 2016 Where Their Transmission Seal Rings Are Highlighted

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.