10 million chains for continuously variable transmissions (CVT) produced

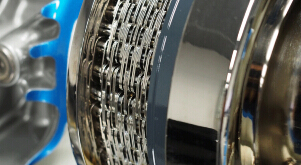

Schaeffler’s CVT chain is a successful product. This innovation was first used in the so-called “Multitronic” transmission in Audi’s A6 models in 1999. Starting with 50 pieces per day, today 6,000 chains roll off the production line at the location in Bühl every working day.

2016-12-14 | Bühl

For Schaeffler, the development and production of the CVT chain has been a continued success story: This innovation was first used in the so-called “Multitronic” transmission in Audi’s A6 models in 1999. Starting with 50 pieces per day, today 6,000 chains roll off the production line at the location in Bühl every working day. And from a global perspective, all indicators point to growth.

It was the multi-link chain by Schaeffler’s LuK brand that made the CVT (continuously variable transmission) suitable for high torques. From development through to volume production readiness – this is an example of the comprehensive expertise Schaeffler offers its customers. "The excellent cooperation between development and production makes the deceicive difference from which our customers have benefited in the past and still benefit from today”, said Norbert Indlekofer, CEO Automotive of Schaeffler AG, at the anniversary ceremony celebrating the production of the 10 millionth CVT chain. Production facilities that are tailored to the relevant requirements are designed and produced by Special Machinery.

Best Performance Award

This sort of operative excellence has been positively received by the customers. Holger Ubben, Vice President of the CVT product line, recently accepted an award in the Best Performance category in Mexico. The prize was awarded by JATCO Mexico for the spontaneous capacity expansion regarding CVT8 transmissions in 2015. Thanks to Special Machinery, it was possible to react extremely flexibly at the Schaeffler location in Buehl. “It is crucial to have in-depth command of the production process, and we have proven this once again”, said Trudbert Kraus, Senior Vice President Operations in the Transmission Systems business division at Schaeffler.

The success story continues

Modern transmission automation concepts such as those on offer from Schaeffler provide an efficient service and convince even more drivers around the world of the benefits of driving without a clutch pedal. Another argument in favor of the CVT is the fact that the gear ratio is continuously adjusted with no interruption to the tractive force, which means that the engine can always be operated in the most favorable area of the datamap in terms of consumption. “An argument in favor of the Schaeffler chain is the degree of efficiency which has an edge over our competitors’ products”, Indlekofer explains. This triggers high demand from customers from all over the world: Construction works for the capacity expansion have already begun at the Schaeffler plant in Puebla/Mexico, so that the demand can be met at the site from late 2017. Preparations for localization activities in China are also well under way. Start of production is scheduled for September 2018.

Schaeffler’s CVT chain is a successful product. This innovation was first used in the so-called “Multitronic” transmission in Audi’s A6 models in 1999. Starting with 50 pieces per day, today 6,000 chains roll off the production line at the location in Bühl every working day.

2016-12-14 | Bühl

For Schaeffler, the development and production of the CVT chain has been a continued success story: This innovation was first used in the so-called “Multitronic” transmission in Audi’s A6 models in 1999. Starting with 50 pieces per day, today 6,000 chains roll off the production line at the location in Bühl every working day. And from a global perspective, all indicators point to growth.

It was the multi-link chain by Schaeffler’s LuK brand that made the CVT (continuously variable transmission) suitable for high torques. From development through to volume production readiness – this is an example of the comprehensive expertise Schaeffler offers its customers. "The excellent cooperation between development and production makes the deceicive difference from which our customers have benefited in the past and still benefit from today”, said Norbert Indlekofer, CEO Automotive of Schaeffler AG, at the anniversary ceremony celebrating the production of the 10 millionth CVT chain. Production facilities that are tailored to the relevant requirements are designed and produced by Special Machinery.

Best Performance Award

This sort of operative excellence has been positively received by the customers. Holger Ubben, Vice President of the CVT product line, recently accepted an award in the Best Performance category in Mexico. The prize was awarded by JATCO Mexico for the spontaneous capacity expansion regarding CVT8 transmissions in 2015. Thanks to Special Machinery, it was possible to react extremely flexibly at the Schaeffler location in Buehl. “It is crucial to have in-depth command of the production process, and we have proven this once again”, said Trudbert Kraus, Senior Vice President Operations in the Transmission Systems business division at Schaeffler.

The success story continues

Modern transmission automation concepts such as those on offer from Schaeffler provide an efficient service and convince even more drivers around the world of the benefits of driving without a clutch pedal. Another argument in favor of the CVT is the fact that the gear ratio is continuously adjusted with no interruption to the tractive force, which means that the engine can always be operated in the most favorable area of the datamap in terms of consumption. “An argument in favor of the Schaeffler chain is the degree of efficiency which has an edge over our competitors’ products”, Indlekofer explains. This triggers high demand from customers from all over the world: Construction works for the capacity expansion have already begun at the Schaeffler plant in Puebla/Mexico, so that the demand can be met at the site from late 2017. Preparations for localization activities in China are also well under way. Start of production is scheduled for September 2018.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Dana to supply axles, driveshafts for 2018 Isuzu FTR Class 6 medium-duty truck

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.