A new era in laser technology-EMO Hannover 2017

It isn't just exhibitors that offer countless innovations in the metalworking industry. The trade fair itself is also delivering some of its own. For the first time, EMO Hannover 2017 is dedicating a separate display area to additive manufacturing processes. For TRUMPF Laser- und Systemtechnik GmbH, this is the ideal arena to demonstrate its expertise in the two key technologies of laser metal fusion (LMF) and laser metal deposition (LMD). The company isn't just focusing on machine solutions but, under the banner "Industrial Additive Technologies", is also providing information on the opportunities that additive technologies have to offer. "Users often still have a great many questions about additive manufacturing, and we're looking to provide answers using practical examples," explains Rainer Grünauer, Head of Additive Manufacturing Sales at TRUMPF.

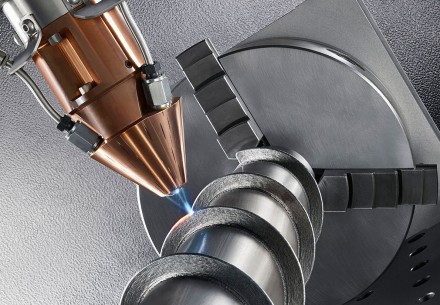

"Additive technologies show their strengths in particular in complex components, while conventional technologies are frequently more than adequate to produce simple components," says Grünauer. And he raises the legitimate question: "Why not harness the best of different worlds in an intelligent mix?" To show how this approach is already being put into practice, TRUMPF is using a tool holder in Hannover that fixes grinding wheels in CNC grinding machines. While the two-part component in the past has consisted of a number of brazed elements - a weak point that has a negative impact on service life - the new design strategy uses additive manufacturing to eliminate this vulnerability. The upper part is created layer by layer on the conventionally produced lower part, the preform, by applying powder in an additive process. Thanks to the design freedom offered by additive manufacturing, this part isn’t just lighter - geometrically optimized wall thicknesses also ensure optimum pressure application.

It isn't just exhibitors that offer countless innovations in the metalworking industry. The trade fair itself is also delivering some of its own. For the first time, EMO Hannover 2017 is dedicating a separate display area to additive manufacturing processes. For TRUMPF Laser- und Systemtechnik GmbH, this is the ideal arena to demonstrate its expertise in the two key technologies of laser metal fusion (LMF) and laser metal deposition (LMD). The company isn't just focusing on machine solutions but, under the banner "Industrial Additive Technologies", is also providing information on the opportunities that additive technologies have to offer. "Users often still have a great many questions about additive manufacturing, and we're looking to provide answers using practical examples," explains Rainer Grünauer, Head of Additive Manufacturing Sales at TRUMPF.

"Additive technologies show their strengths in particular in complex components, while conventional technologies are frequently more than adequate to produce simple components," says Grünauer. And he raises the legitimate question: "Why not harness the best of different worlds in an intelligent mix?" To show how this approach is already being put into practice, TRUMPF is using a tool holder in Hannover that fixes grinding wheels in CNC grinding machines. While the two-part component in the past has consisted of a number of brazed elements - a weak point that has a negative impact on service life - the new design strategy uses additive manufacturing to eliminate this vulnerability. The upper part is created layer by layer on the conventionally produced lower part, the preform, by applying powder in an additive process. Thanks to the design freedom offered by additive manufacturing, this part isn’t just lighter - geometrically optimized wall thicknesses also ensure optimum pressure application.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next SKF helps keep Erdinger Weißbräu brewery flowing

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.