Linear Bearings: Understanding the 2:1 Ratio and How to Overcome the Stick-Slip Phenomenon

Back in the 1980s, Pacific Bearing Co. (PBC) invented and commercialized plain bearings, which were sized to be interchangeable with linear ball bearings.

Plain bearings worked very well in certain applications—mainly those in environments that were hot, cold, or dirty, or included high vibrations, high static loads, or non-lubricated and short strokes less than twice the bearing’s length. These were just the sort of applications in which recirculating ball bearings failed miserably.

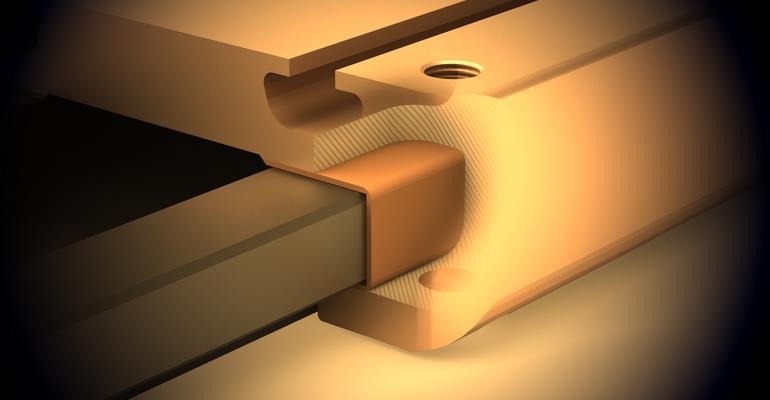

But plain bearings were quickly found to be unacceptable replacements in applications requiring low coefficients of friction, high speeds, or high moment loads. In fact, some applications with high moment loads caused plain bearings to simply bind up; all motion would cease or become jerky (also known as stick-slip motion). Early on, the assumption was that plain bearings could not handle the same moment loads as equivalently sized recirculating ball bearings.

What engineers failed to realize was that there is a geometric relationship that describe the allowable working space of plain bearings. This went unrecognized until PBC published the Binding Ratio (aka, 2:1 Ratio) in the 1990s. Two decades later, some engineers still don’t realize the scope of this rule and that it applies to all linear motion systems, not just plain bearings. They also don’t know that the Binding Ratio isn’t always 2:1. It varies with the application and can be larger or smaller than 2:1.

The Binding Ratio

The “Binding Ratio” is defined as the maximum ratio of moment-arm distance to bearing length that will not bind (prevent motion). It is often displayed numerically as X:Y, where X is the moment-arm distance and Y is bearing length. Typically, X is divided by Y so that the ratio can be expressed as X∕Y:1. It is commonly simplified to 2:1.

Back in the 1980s, Pacific Bearing Co. (PBC) invented and commercialized plain bearings, which were sized to be interchangeable with linear ball bearings.

Plain bearings worked very well in certain applications—mainly those in environments that were hot, cold, or dirty, or included high vibrations, high static loads, or non-lubricated and short strokes less than twice the bearing’s length. These were just the sort of applications in which recirculating ball bearings failed miserably.

But plain bearings were quickly found to be unacceptable replacements in applications requiring low coefficients of friction, high speeds, or high moment loads. In fact, some applications with high moment loads caused plain bearings to simply bind up; all motion would cease or become jerky (also known as stick-slip motion). Early on, the assumption was that plain bearings could not handle the same moment loads as equivalently sized recirculating ball bearings.

What engineers failed to realize was that there is a geometric relationship that describe the allowable working space of plain bearings. This went unrecognized until PBC published the Binding Ratio (aka, 2:1 Ratio) in the 1990s. Two decades later, some engineers still don’t realize the scope of this rule and that it applies to all linear motion systems, not just plain bearings. They also don’t know that the Binding Ratio isn’t always 2:1. It varies with the application and can be larger or smaller than 2:1.

The Binding Ratio

The “Binding Ratio” is defined as the maximum ratio of moment-arm distance to bearing length that will not bind (prevent motion). It is often displayed numerically as X:Y, where X is the moment-arm distance and Y is bearing length. Typically, X is divided by Y so that the ratio can be expressed as X∕Y:1. It is commonly simplified to 2:1.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Successful 2nd Edition of ‘The Bearing Reliability Conference & Expo’ was held in Dortmund

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.