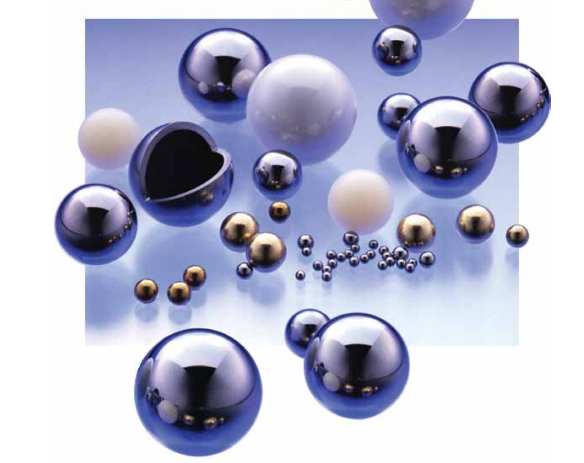

Selecting the Right Precision Ball Material for Aggressive Environments

Balls are a common mechanical component used in nearly all complex—and many simple— mechanical products. The critical nature of balls is illustrated by the fact that ball bearing factories were one of the primary targets for Allied bombers seeking to disrupt the German war industry during World War II. While the vast majority of balls are made of some type of steel, steel’s relatively weak resistance to chemical attack means that applications involving aggressive environments generally require a more exotic material. This article will examine the major materials used to enhance balls to resist aggressive environments and help in selecting the right one. Brass Balls Brass balls provide excellent resistance to corrosion by water, including seawater, and also resist the corrosive effects of fuel oil, gasoline, butane, dry carbon oxide, benzene and similar chemical agents. However, it should be noted that brass can be unstable in the presence of acids and bases. Another key advantage of brass balls is their cost, which is substantially lower than other corrosion-resisting balls. Brass balls have a Rockwell B hardness of 75 to 87, which makes them suitable for applications where the balls are only required to withstand a medium load. Brass provides excellent electrical conductivity, so it is well suited for many electrical applications. A silver coating is sometimes applied to brass balls to improve their electrical conductivity and corrosion resistance to even higher levels. Brass balls’ combination of resistance to corrosion from water and high hardness make them suitable for water valves, including high-pressure applications. Brass valves are even used in fire nozzles where they must withstand high pressures and flow rates. Brass balls are frequently used in electrical equipment, most often in the role of connectors that make an electrical circuit. For example, brass balls are used in wireless power devices, data storage equipment, heating units and kitchen applications. Another common application is the use of brass balls in the pumps of sprayers used to apply fertilizer and pesticides to lawns and crops.

Monel Balls Monel balls provide an even higher resistance to corrosion than brass balls. Monel is composed primarily of nickel and copper, and also has smaller amounts of other elements such as iron, silicon, manganese, carbon, aluminum, titanium and sulfur. Monel balls are impervious to the effects of fresh water, salt water, steam, petroleum products, ammonia, acids, many bases and calcium chloride. Monel also has a relatively high tensile strength of 79 to 90 Kpsi and yield strength of 24 to 40 Kpsi. Monel has a hardness of 85 to 95 Rockwell B, while its sister alloy, k-monel can be hardened to about Rockwell 27 C. K-monel also offers superior resistance to bases. On the other hand, monel balls are relatively expensive because of the difficulty involved in machining them.

Monel balls are frequently used in pump, valve and metering applications in water treatment and chemical plants because they resist attacks by a wide range of chemicals, and because their strength enables them to withstand high flows and pressures. In particular, monel balls’ ability to withstand ammonia makes them particularly useful in wastewater treatment and chemical plants. Monel balls’ corrosion resistance enables them to provide longer life than chrome or stainless steel balls in water supply, wastewater and hydroelectric applications. They are used in meters that measure the flow of liquid and gases because their ability to withstand most any chemical makes for a more versatile instrument. Since monel balls are resistant to both petroleum oils and water, they are ideal for valves in the oil and gas industry. The added hardness of k-monel makes them well suited for use in bearings that must survive aggressive environments.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Dana Introduces Range of Jack-up Gearboxes for Offshore Applications

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.