Rotary axis optimization software

Marposs introduces AxiCheck, a software package with a graphic interface that analyzes data collected with Marposs probes, processing it in a graphic format to easily determine machine operating. AxiCheck helps increase production capacity by quickly and accurately inspecting the machine’s state of health, allowing users to identify and correct errors that may impact the workpiece, as well as planning maintenance operations in advance. This reduces the number of reject parts, particularly when dealing with single batches of expensive part production.

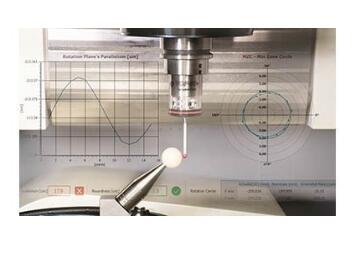

Parallelism of the axis of rotation and accuracy of its center are fundamental characteristics for the proper functioning of a machine tool with rotary axes. AxiCheck takes measurement to determine the reference values on a calibration sphere, mounted on the machine table to determine the machine’s operating health. Designed for use on 3- and 5-axis machines, AxiCheck is capable of monitoring and optimizing the performance of the rotating axes (5 Ax) while detecting any deterioration in the machine’s linear axes (3 Ax) in real time. It also features warning and alarm messages to alert the user if the measurement is out of tolerance.

AxiCheck features:

- Graphical machine error detection

- Increase in production capacity

- Reduction of scrap, rework

- Visualization of error evolution with alarm threshold for maintenance planning

- Detection of parallelism errors of the rotary axes and centers of rotation of the machine

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.