Coordinates to the Future

Double-axis coordinate measuring machines (CMMs) were first produced in the 1950s by the Ferranti Company of Scotland to measure precision military components. Three-axis models appeared in the 1960s, and the first working CMM was developed and sold by Browne & Sharpe in Melbourne, England.

During seven decades of evolution, the size and precision of CMMs have continually improved thanks to a host of innovators. Relatively early advances range from the 3D-measuring probe and motorized probes to metrology software and no-touch sensors, laser trackers and portable systems. Fast forward to today, and a variety of novel sensors compete to supplant the familiar ruby ball.

Flexing Into the Future

Needless to say, CMMs are an integral part of the complex process of manufacturing. And next-generation systems are on the horizon to best support manufacturers as they adapt to new technologies and adhere to more stringent requirements.

To this end, Thomas Ayers, sales and business development director (Southeast) of Ohio-based Advance Industrial Measurement Systems Inc. (AIMS), identifies several trends. “I think manufacturing flexibility and multi-sensor systems are one of the biggest drivers today. CMMs are mature. Tactile probing and even scanning do good geometry and dimensional inspections of a product.

“However, many parts have other characteristics, surface finish being one,” Ayers continues. “Unfortunately, customers must move parts from machine to machine for inspections, which is lost time and resources. So, CMMs that can grab a surface finish probe, then pick up optical sensors and look for defects or cross hatches or things that you didn’t normally do on a conventional CMM—that’s lately been a big push. Now CMMs can do (inspections) essentially right in their own manufacturing cell. Between the five-axis CMM being on the floor and the savings customers get from not going back and forth, they’re increasing their production rate by significant measures.”

Zeiss Group’s Industrial Quality Solutions unit provides a concept called plug-and-play, notes David Wick, manager of product management. “We can connect a tactile sensor, a non-contact sensor that uses a laser beam or a non-contact sensor using white light, or connect a surface roughness sensor that effectively runs a stylus across the surface to measure its roughness, all in a plug-and-play mode,” Wick explains. “We use the same software across all those sensors and the same user interface. So, it makes the machine very flexible.”

The automotive industry needs CMMs to integrate with “customized automation, equipment, loaders, carts and robots to feed parts into the machine and then remove them to improve the customer’s productivity and efficiency,” Wick adds. “We’re designing a solution that’s more than just a CMM—we’re providing a whole solution, doing the installation, the software integration and making sure it’s running properly for the customer to achieve their faster production goals.”

Customized Coordination

Industry often needs customized solutions to improve efficiency, quality and reduce costs.

Helmel Engineering Products Inc., whose machines use mechanical bearings as opposed to air bearings, has “a point of uniqueness, yet once the trend emerged that manufacturers wanted the capabilities of a coordinate measuring machine closer to production, meaning on the manufacturing floor, our competitors all discovered mechanical bearings,” Arthur Whistler, vice president of sales and marketing for the Niagara Falls, N.Y.-based company says. “And that’s what they’re doing now for their shop floor machines. It’s what we’ve done, as they are more robust, more durable and are less fussy. Air bearing surfaces are far more sensitive, as are the bearings themselves.” Whistler says Helmel’s CMMs “don’t see reliability issues,” and they continue to service machines the company built more than 40 years ago.

Joe Szymanski, vice president of sales and marketing at LK Metrology Inc., says the New Hudson, Mich., company is “trying to generate and combine multipurpose sensors in our advanced hardware and software. I think, looking from 30,000 feet, if you have things that you’re going to be doing 60, 70, 80% of the time, people might go buy a dedicated machine. But if it’s 40-60%, that’s when you can use a CMM with a variety of sensor technologies and software. But that will be dictated by precision and accuracy requirements, complex geometries and repeatability.”

LK Metrology also sees increasing automation integration done in cell environments. Requirements for real-time data analysis and data requirements consistent with Industry 4.0 factor in. Szymanski notes that modular designs and “good strong training from the OEMs and their distribution teams” are essential, as is software-user friendliness.”

Overcoming Challenges

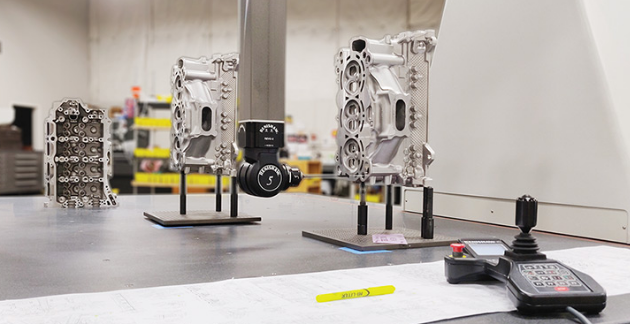

Wick of Zeiss notes that system accuracy, or measurement uncertainty, isn’t changing. “What we see as challenging are the surface roughness or surface smoothness requirements of certain surfaces on an internal combustion engine block. That’s because of the volume of engine blocks made per day, week, month, and the smoothness that those surfaces need in order for the pistons to move up and down or the valves and gaskets to seal.”

Measuring the critical dimensions of a fan blade for jet engines is also challenging. “We do have solutions for both of them, but they’re pretty tough,” Wick says.

AIMS finds challenge at both ends of the spectrum. This includes new geometries created with a 3D printer, often with very complex shapes that can defy conventional straight probes. The result is the five-axis probe system and custom styli—some with 3D printed styli to reach those geometries.

Automation brings its own set of issues. “Systems are so much faster, you’ve got to be able to gauge something quicker and accommodate that cycle time,” Wick says. “Now you’ve got machine tools that can spit out a part in two minutes, but can you really get it to a gauge and get it gauged in two minutes?”

Helmel Engineering is comparatively small, but has 50 years of experience specializing in mechanical bearing moving bridge machines, which it says are suitable for 90% of the manufacturing market. “Many applications that require high accuracy are misapplied,” Whistler laments. “I think there’s some wishful thinking about the outcomes, but we are going to higher resolution scales, using more of the mapping tools that are available to compensate or correct the 21 degrees of freedom that three-axis orthogonal structures all have.”

LK Metrology finds that its customers are demanding higher precision and tighter tolerances, and therefore more stringent accuracy standards. “Micro-metrology is introducing [challenges] for a CMM to do submicron measurement with reliability, reproducibility and traceability,” Szymanski says. “The big thing now, with Industry 4.0, is data analysis and data capturing of in-process monitoring.”

Another challenge, he says, is inspection speed. “Everybody wants to have inspection enhanced through the whole measurement cycle. Many, still in 2023, haven’t bought into the newest technologies. But relative to that, you can upgrade old devices with new computers, new encoders or new scales. Thus, customers can attack enhancing their quality tools today.”

Next-Gen Efficiencies

LK Metrology is working on tailored solutions to meet increasingly stringent requirements. “We work with people trying to deploy some of the advanced technologies and giving customers better and enhanced support,” Szymanski says. “Which means customization, maybe advanced sensors, enhanced software with maybe some specialty modules.

“We’re also improving maintenance and predictive maintenance,” he says, “which I think Industry 4.0-type software platforms are getting better at, plus recognizing the importance of flexible design, lean manufacturing and process optimization, even elements of AI being introduced into our world. It’s forced our industry to take more of a consultative sales approach and get into the nitty-gritty of our customers and really trying to understand what their process is.”

Many shops produce a different part every day, Ayers points out, compared to the automotive or aerospace industries running the same part for weeks. This requires greater agility, but such flexibility and ability to make quick changeovers is hindered by the ongoing shortage of skilled manufacturing workers.

“I wish we could get more kids engaged in engineering and science, and want to do more manufacturing,” Ayers says. “We do provide customers with training, part programming, but more often we’re doing complete turnkey solutions to help them offset their internal labor gap.”

Szymanski also has some thoughts about the future. Among the top technologies he says companies are looking to add are:

Advanced materials in machine building

Enhanced sensors

Artificial intelligence

“Some of you might even want to call a hybrid measurement system, maybe even augmented reality or virtual reality plus cloud-based data management for the customer’s miniaturization,” he adds. “However, customers rely on us meeting application requirements, the specific needs and required technology, but as always, a focus on accuracies and precisions, recognizing the complexity of the parts and the size, speed, throughput, velocity, flexibility and versatility while monitoring traceability and calibration, data analysis and reporting. Getting to the monetary side of it, certainly cost of ownership.”

To CMM or Not to CMM

When does it make sense to use a CMM versus a competing technology, such as structured light system?

Not surprisingly, there are pros and cons for everything. For example, Wick cautions that a handheld laser or a structured light system will give a measurement uncertainty that is about five or 10 times what someone can get with a coordinate measurement machine.

“One of the things that’s making next-generation systems more efficient is that the actual firmware of the machine is being optimized for specific measurements,” he explains. “There are ways that you can optimize the firmware so that the machine actually moves faster in a given set of measurements than it would otherwise. Hence, speeding up the measurement program, hence improving the customer’s productivity because you can measure more of the same unit per day, per week.”

AI is also on Szymanski’s list of upcoming technologies, as are growth in composite material inspection, 3D scanning and digitization. And, he notes, changes in the automotive industry with electric vehicle batteries may require customized prototyping. “On a larger scale, you do have architectural and construction inspection, so the advancements ‘nearly here’ are quite varied,” Szymanski concludes.

Optical scanning also is gaining momentum, according to Whistler, who spoke from a recent trade show. “More and more people are jumping into the optical scanning side of things. Not just line scanning, but whole-field camera systems that create point clouds, and there the accuracy is improving and they’re putting cameras on robots.”

Elsewhere, he continues, end users are replacing “traditional design-and-build hard gauges with more flexible and reprogrammable systems; production engineers and operators don’t want to learn how to program the machines. We must, in some cases, customize special software on the output end so that it looks more like the hard gauge software they were accustomed to. Some of the operators on the shop floor wear gloves, so we have to design and build fixtures that don’t require any tools, that can adjust for a range of product.”

Meanwhile, the industry as a whole is grappling with 3D-printed parts, an issue that spans medical, aviation, power generation and automotive. “This brings up a totally new complexity for a part that couldn’t have been made before,” Ayers acknowledges.

But there are plenty of exciting solutions in the works. The AI revolution may even spark the dawn of self-aware machines.

“When I look at the drawing board from a software perspective, we’re very close to giving the CMM the ability to program itself,” Ayers says. “There are some software packages already that can read the PMI or model-based definitions from the CAD source and understand what the report’s got to look like and understand where all the features are. The limiting factor right now is there’s not that many customers that have embraced taking the time to put all the model-based definitions or PMI data into their CAD systems.

“There are software platforms on the market already that claim (self-programming) but it’s really not been accepted across the whole space,” he continues. “So, I believe one of the biggest changes that you’ll see in CMMs in the next five years is that ability to reduce the complexity of programming.”

The Future of CMM Metrology Starts Upstream

Clearly, the underlying purpose of industrial metrology remains mitigation of risk and ensuring a common viewpoint of the form, fit and function of components. But the scope of the technology is changing as manufacturers seek to further boost their quality and efficiency.

As a result, industry best practices now seek to “drive quality upstream,” explains Dan Skulan, general manager, Renishaw Inc., Chicago. “Inspection at the end of a process is a very expensive way to control quality.”

Skulan sees smart manufacturers deploying metrology much earlier in the process, starting with the raw materials coming in. “Inspection of a raw forging going into a machining operation will tell you how deep of a cut you need to make in the final part.”

Thus, executing metrology prior to cutting, probing directly on the machine and using closed-loop control and adaptive cutting, is gaining prominence. While CMM can be used between a rough cut and a final operation, inspection can occur directly on CNC machines using machine tool probes. This moves up metrology verification of a component’s form, shape and size prior to the cutting phase.

Nowhere is this more important than aerospace and medical.

“In the aerospace industry, where the forging for a bladed disc inside of an aircraft engine has very tight tolerances and is very expensive, there we deploy metrology prior to cutting to validate the workpiece size and shape, and then feed that information directly into the cutting process so that the cutting can occur with the highest potential quality, lowest risk of damage to the part and the tools,” Skulan says. “It ensures the highest throughput and avoids dead air cutting. We provide information on what the raw material is and the cutting program adapts accordingly.

“Medical has a lot of freeform parts and a lot of parts now are being 3D printed with less excess stock on them,” he continues. “So, you need to validate the part right up front and know where the material is so that when you cut it, you get full cleanup and you don’t scrap parts.”

Revving Up Data

Renishaw provides three- and five-axis measurement systems.

“The speed that you can measure is dictated by the stiffness of the structure and acceleration of the movements relative to the stiffness of the structure,” Skulan notes. “Moving linearly, you’re just taking a single point in space and can use a standard three-axis system to measure at a relatively slow speed using a single-point touch mechanism, no problem. But when you start to scan, especially on round or curved surfaces, which aerospace, medical and automotive use extensively, there’s a lot of curved surfaces.”

Scans require multiple data points and staying in contact with the surface. Renishaw’s five-axis REVO system is designed to raise the speed threshold for CMM scanning.

“When you scan, you’re accelerating into the curve and decelerating out of it, and you always have stresses on the structure. The stiffness of the structure of a CMM limits how fast and accurately you can measure.”

REVO can scan at 500 millimeters per second “without any loss of accuracy because the fast motion is done by the head, not the structure,” Skulan says. Machine stiffness issues are avoided by their “relatively high-resonant frequency REVO head, which is equipped with an internal laser system that detects where the stylus point is in space in real time.”

Skulan emphasizes that curved, contoured surfaces and rapid, large data collection without loss of accuracy present challenges with traditional three-axis CMM systems.

“We contact the part like a traditional CMM (with REVO), but there’s a laser beam that shoots down through the inside of the stylus that measures the location of the back of the ball in space at all times. And physics—acceleration times mass—determines the bending and twisting. There is no mass with laser, so it doesn’t bend no matter how fast you move it. It detects the bends that occur naturally in all mechanical structures when they move at a rapid acceleration, but it doesn’t affect the measurement because we measure the effect of that bend in real time. And so, the output of our device is a combination of contact laser-based, no mass light that’s measuring the backside of the ball and standard probe. It’s the best of both worlds.”

Renishaw reinvests about 15% of its annual revenue into research and development. This includes “consistent” investment into REVO, according to Skulan, citing recent advances in surface finish, video, ultrasonic thickness, temperature and 3D-structured light.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.