Open “the last black box”! The performance of China Spindle bearings in operation for nearly 4 years exceeded expectations

"Since it was put into operation in 2020, the China spindle bearing wind turbines used by Leling Wind Farm have maintained a record of zero failure, and key indicators such as operating temperature, iron content in lubricating oil and CMS vibration monitoring are better than industry standards, especially in temperature control, which has always been maintained at about 40 degrees Celsius, significantly lower than the critical value of 65 degrees Celsius. Good and consistent performance."

Recently, "China Energy News" reporter visited the Shandong branch of Guohua Investment Leling Wind farm, site director Che Qinghua said so.

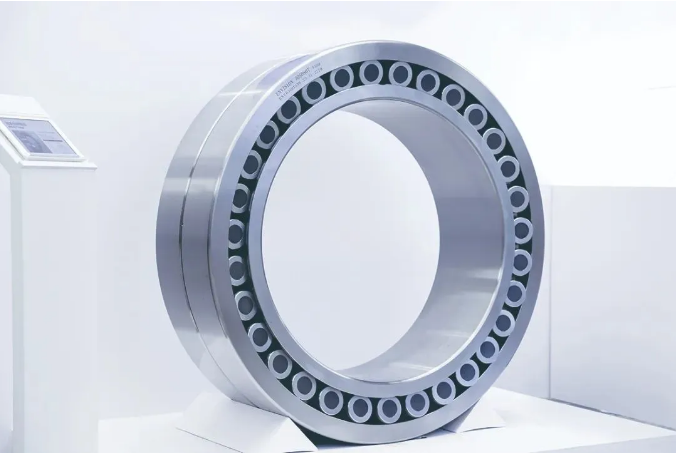

The spindle bearing, as one of the core components of wind power equipment, has strict requirements for accuracy, load capacity and service life in its development and manufacturing, and has long been regarded as the last hurdle on the road to the localization of wind power equipment.

As the wind power industry seeks to reduce costs and improve efficiency, China's wind power equipment manufacturers have gradually overcome technical barriers to achieve the localization of this key component.

Leling Wind Farm located in the North China Plain, in the face of complex wind conditions, the wind turbine equipped with China Spindle bearings still performs well, surpassing the industry average.

Leling Wind Farm, located in the North China Plain, has made remarkable achievements in the face of complex and stable operation for four years.

Leling Wind Farm is a typical plain wind farm, with dozens of typhoon power units scattered in the vast corn fields.

It gathers the air flow from Bohai Bay and the wind from the North China Plain. Although the annual average wind speed is only 4.96 m/s, the instantaneous wind speed is high and the direction is changeable, and the frequent encounter with high turbulence and extreme weather brings unbalanced load to the wind wheel, and the pressure on the spindle bearing is also very severe.

However, since its full capacity has been connected to the grid, Leling Wind Farm has been able to generate electricity for an average of 2,500 hours per year, and the cumulative power generation has reached 920 million KWH, enough to meet the electricity demand of about 150,000 households for a year.

Behind these achievements, the China spindle bearing is indispensable. Leling Wind Farm's 34 individual Vision Energy wind turbines with a capacity of 3.0 MW are equipped with self-developed spindle bearings, and their operational performance is impressive.

"The spindle bearing is the core of the operation of the fan, and the temperature is an important reference for the good operation of the equipment." Che explained, "Good lubrication can reduce wear and tear, thus preventing overheating. Leling Wind Farm's domestic main bearing operating temperature has always been maintained at about 40 degrees Celsius, far lower than the industry standard of 65 degrees Celsius."

In addition to temperature control, monitoring data also shows that the wind farm's China spindle bearings have low wear and the iron content in lubricating oil is also lower than the industry average.

Through the CMS vibration monitoring data and the real-time analysis of the Galileo platform, the health status of all self-developed spindle bearings is within the normal range.

Break through the "black box" and promote the wind power industry to reduce costs and increase efficiency

"Before 2019, China's wind power spindle bearing market was almost entirely dominated by imported brands." A main bearing expert of Vision Energy revealed in an interview, "The development and production of spindle bearings is very complicated, and the challenges faced by new entrants are huge."

High quality steel is used in the main bearing, which reduces harmful impurities through a unique smelting process and enhances the durability and impact resistance of the bearing.

In addition, compared with similar imported products, self-developed spindle bearings have higher processing accuracy, making the operation smoother, the heat generated by friction is lower, and the reliability is stronger.

In addition to technological innovation, China spindle bearing manufacturers also use the advantages of customization to expand the market. "Based on China's unique wind conditions, we designed main bearings that are more suitable for the local environment, combined with intelligent systems to identify risks in advance, optimize operation and maintenance strategies, and improve power generation efficiency." The expert explained further.

"In the past, when there was a problem with imported main bearings, the supplier could take weeks or even months to respond and replace, but now, the rapid response of domestic main bearings greatly reduces the maintenance time and reduces the downtime loss." Che Qinghua said.

Independent innovation to enhance the competitiveness of China's wind power industry

Despite a late start, the domestic wind power industry is rising rapidly. With the increase in the application of domestic core components, the operation and maintenance efficiency of wind farms is also constantly improving.

According to Liu Fei, deputy general manager of the fifth district of the Grand Site of the Vision Energy Engineering service and asset Management Center, with the popularization of domestic components and technological progress, the number of wind farm operation and maintenance personnel has been significantly reduced, from the original dozen to seven or eight, or even less.

At present, when major central enterprises purchase spindle bearings, the proportion of localization is gradually increasing, and it is expected that the localization rate will rise from about 10% in 2021 to about 65% this year.

Since its first application in 2019, Vision has developed 14 self-developed spindle bearings used in 508 projects worldwide, including more than 1,500 fans exported to overseas markets, none of which has failed since mass production.

The Global Wind Energy Council predicts that global wind power installations will increase by more than 1 terawatt in the next decade, and Chinese-made wind power equipment will play an important role in the global green transition.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Service solutions for electrified vehicles: Schaeffler Vehicle Lifetime Solutions offers what the industry needs

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.