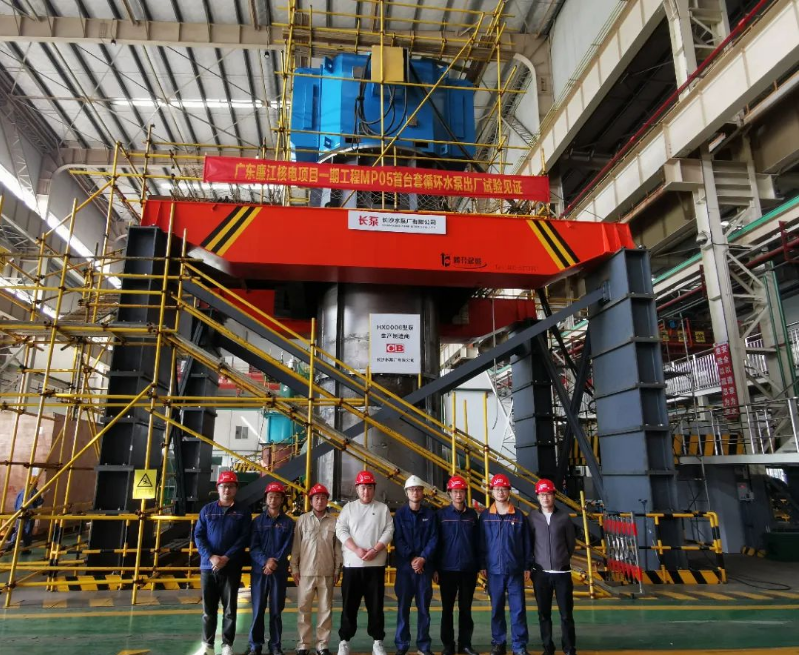

The first MP05 circulating water pump of the first phase of the Guangdong Lianjiang project undertaken by Chang Pump was successfully accepted

Recently, the factory test witnessing ceremony of the MP05 circulating water pump of the first phase of the Guangdong Lianjiang Nuclear Power Project was held at Changsha Pump Factory Co., Ltd. Representatives from the Zhanjiang Nuclear Power owner, Shanghai Nuclear Engineering Research Institute and Shandong Institute attended the witnessing meeting.

Guangdong Lianjiang Nuclear Power Project is located in Lianjiang City, Guangdong Province. It is the first nuclear power plant of State Power Investment Corporation in Guangdong Province. The project plans to build 6 advanced third-generation nuclear power units with a total installed capacity of 8,620 megawatts. These units will fully adopt the third-generation passive pressurized water reactor nuclear power technology to ensure that the highest international safety standards are met. This project is the first nuclear power plant in China to use seawater secondary circulation cooling technology. This not only represents the first nuclear power project of State Power Investment Corporation in Guangdong, but also a model of domestic nuclear power technology innovation. By introducing seawater secondary circulation cooling technology for the first time, the project has injected new vitality into the sustainable development of the nuclear power industry.

Changsha Pump Factory Co., Ltd. provides MP05 circulating water pumps for the first phase of the project. The pump is vertically installed and supported by a single foundation. The pump shaft is equipped with a lubricating internal pipe and adopts a large internal pipe structure. In order to increase the service life of the bearing, wear-resistant water-lubricated imported AR guide bearings are selected. In order to ensure the performance of the water pump, the excellent hydraulic model independently developed and optimized by our company is selected. In order to ensure the service life of the unit and reduce the impact of seawater corrosion, the pump unit is made of super duplex stainless steel with anti-corrosion coating and equipped with impressed current cathodic protection equipment. The pump unit has a power of 4500KW, an overall height of 8 floors, a length of nearly 25 meters, a pump outlet diameter of 2800mm, and a pump unit weight of 200 tons. The processing, assembly and testing are very difficult. After the full-length shaft performance acceptance test in the factory, its performance fully meets or even exceeds the requirements in the agreement and has been unanimously recognized by all parties. The full-length shaft real machine performance test acceptance of the first vertical large-scale circulating water pump of Lianjiang Nuclear Power Plant passed the one-time acceptance, which marks that the company has taken another solid step towards the goal of becoming a comprehensive manufacturer of large-scale pump products.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next ABACO SYSTEMS' SBC3215 HIGH-PERFORMANCE, RUGGED SINGLE-BOARD COMPUTER

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.