SZSE Hosts Earnings Conference Featuring Robot Industry Chain Firms

May 15, 2024 – The Shenzhen Stock Exchange (SZSE) will hold a collective earnings conference for listed companies under the theme "Precision in Motion • Empowering New Manufacturing," focusing on the robotics industry chain. The event serves not only as a bridge between capital markets and the real economy but also highlights the strategic opportunities for the bearing sector amid the robotics industry boom.

As a key initiative to advance new quality productive forces, the conference brings together robotics industry chain companies, facilitating investor engagement through hybrid (online + offline) formats to accelerate technology commercialization and market expansion. Robotics, as a core driver of new manufacturing, requires not only technological breakthroughs but also sustained capital market support. By refining its service ecosystem, the SZSE aims to empower robotics enterprises to lead smart manufacturing upgrades and industrial chain modernization—with this conference being a tactical implementation of that strategy.

The Critical Piece in Robotics' Supply Chain Puzzle

The event features industry leaders including Changshu Bearing (300718), Everwin Precision (300115), JWIPC, and Googol Technology. Among them, Changshu Bearing and Everwin Precision—representing the bearing sector—demonstrate the segment’s competitive edge in robotics core components:

CSB Bearing: A 30-Year Pioneer in Self-Lubricating Bearing Technology

With nearly three decades of expertise in self-lubricating bearings, CSB Bearing (300718) has achieved a breakthrough with its "titanium alloy microporous self-lubricating" technology, reducing the friction coefficient to 0.03—significantly lower than Germany’s IGUS (0.08)—while extending service life to over 15,000 hours, far surpassing industry standards.

The company has secured a deep collaboration with Unitree Robotics, supplying joint bearings for its H1/G1 humanoid robots. Orders in Q1 2025 surged 300% YoY, with the per-unit value increasing from RMB 500 to RMB 1,200 (including lead screw components), reflecting higher integration and performance demands.

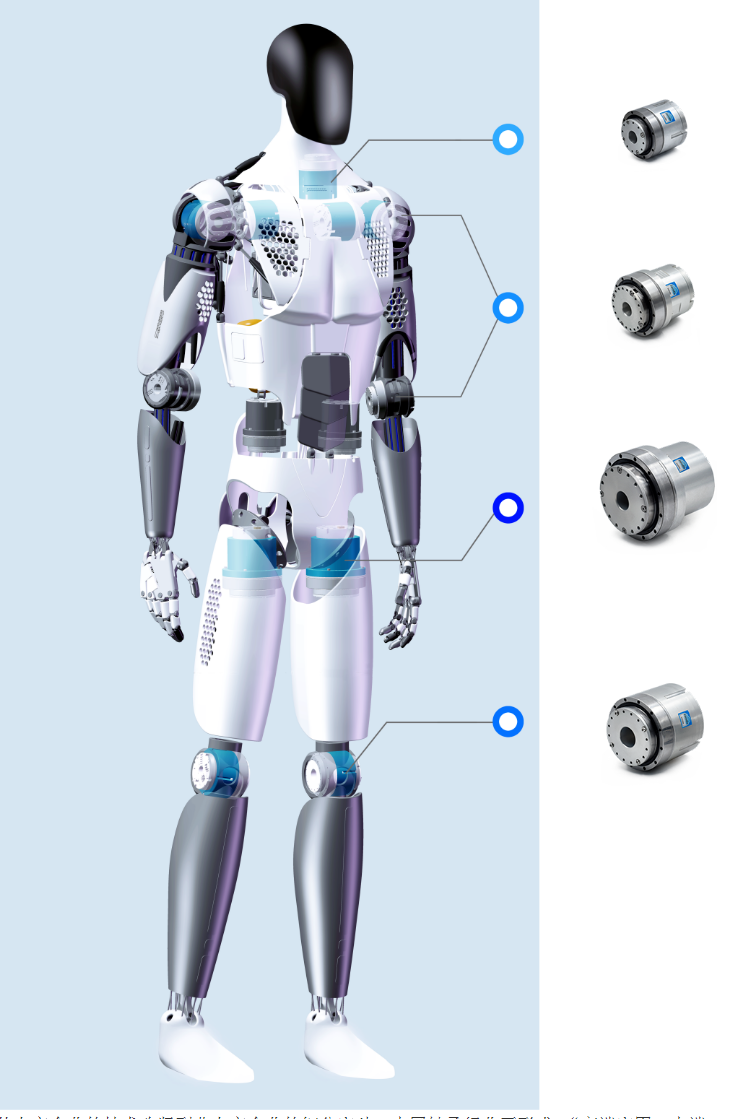

Everwin Precision: Layout of the embodied intelligence industry, its Tianji Robot and Everwin Robot focus on the research and development of manipulators, dexterous hands and embodied robot components respectively. Its rotary actuators, joint torque sensors and other products have been unveiled at the CES exhibition, making it a key supplier for global humanoid robot customers.

"Hidden Champions" in Robotic Joints

1. Technological breakthroughs open up incremental markets

Robot joints have strict requirements on the accuracy, wear resistance and load capacity of bearings. Taking Changsheng Bearing as an example, its self-lubricating bearings have a yield rate of 98.7% when adapting to high-frequency motion scenes of robots, far exceeding the industry average of 92%. In the field of humanoid robots, a single device needs to be equipped with 20-40 rotary actuators, each actuator contains 2-3 sets of precision bearings, and the market space is huge. Toubao Research Institute predicts that the global market size of humanoid robot bearings will reach 1.81 billion to 3.08 billion yuan in 2030, with an annual compound growth rate of more than 70%.

2. Domestic substitution and industrial chain synergy

Domestic bearing companies are accelerating their breakthroughs in the high-end market. Luoyang Hongyuan's crossed roller bearings have occupied 80% of the domestic market share, and the product life has been increased from 2,000 hours to 8,000 hours; Changsheng Bearing's self-lubricating bearings cost 35% lower than Japan's Oiles, and have successfully supported leading companies such as Yihuatong and BYD. In addition, the cross-border layout of car companies (such as Xiaomi and Weilai) promotes the synergy between robot manufacturing and the automotive supply chain, further amplifying the scale advantages of bearing companies.

3. Scenario expansion and technology integration

In addition to industrial robots, the demand for bearings in scenarios such as service robots and medical robots is also growing rapidly. Changsheng Bearing's self-lubricating bearings have been adapted to extreme working conditions from -200℃ to +300℃, and have verified their reliability in hydrogen compressors, semiconductor robotic arms and other fields. In the future, technological breakthroughs such as "intelligent bearings" with integrated sensors and bionic self-lubricating materials will further expand the application boundaries of bearings in the field of robots.

Robot strategy layout of other listed bearing companies

In addition to Changsheng Bearing and Everwin Precision, many domestic listed bearing companies have deeply entered the core components track of robots, forming differentiated technical barriers:

1. XCC*ZXZ (603667): Domestic substitution and Tesla supply chain dual-wheel drive

As the global leader in precision bearing rings, XCC*ZXZ has made breakthroughs in harmonic reducer bearings and RV reducer bearings, becoming a core supplier of domestic reducer manufacturers such as Green Harmonic and Nantong Zhenkang. Its self-developed ceramic bearings have a lifespan three times higher than steel bearings, high temperature resistance of 800℃, and have passed the certification of Tesla drive motor bearing rings. It is expected that the annual compound growth rate of delivery volume will exceed 50% in the next five years. The company also deploys reverse planetary roller screws to adapt to the high-precision transmission needs of humanoid robot joints. In Q1 2025, the revenue of the screw business increased by 120% year-on-year.

2. SINOMACH Precision (002046): Space-grade technology strikes the robot market

Relying on the technical accumulation of Luoyang Bearing Research Institute (LYC), SINOMACH Precision has developed a cross roller bearing with an accuracy of ±1 micron, breaking the monopoly of Japan's THK and NSK, and has been applied in batches to domestic industrial robot joints such as Estun and Siasun. Its aerospace-grade precision bearing technology has been successfully transformed into the civilian field, and the product life is 40% higher than that of similar imported products. The market share in scenes such as collaborative robots and medical robots has risen rapidly.

3. Redick (300652): Screw + bearing dual-wheel drive humanoid robot

Through the acquisition of the precision of the planetary roller screw track, Redick has developed a micro ball screw with an accuracy of C3, which is suitable for the fine movement of the joints of the dexterous hand, and has reached cooperation with many domestic dexterous hand manufacturers. Its planetary roller screw production capacity reaches 10,000 pieces/month, which can quickly respond to the mass production needs of Tesla Optimus and other products. The value of a single humanoid robot screw exceeds 5,000 yuan. At the same time, the company's traditional wheel hub bearing business has been transformed into an intelligent one, and the yield rate has been increased to 98.5%, providing high reliability support for the robot chassis drive system.

4. SZZH (430418): The hidden champion of needle roller bearings

As a company listed on the New Third Board, SZZH's ultra-thin precision needle roller bearings have the same technical indicators as foreign products and are widely used in industrial robot RV reducers and harmonic reducers. Its technical accumulation in the aerospace field (such as the development of roller bearings for the body of Commercial Aircraft Corporation of China) feeds back to the robot business, and the stability of its products under extreme working conditions is significantly better than that of its peers. In 2024, the company's robot bearing business revenue will increase from 5% to 12%, becoming the second growth curve.

5. SL (836743): A representative of precision bearings

SL, listed on the New Third Board, focuses on cross roller bearings and harmonic reducer bearings. Its products have a precision of P2 and are suitable for the high-speed and high-load requirements of industrial robots. Its RV reducer tapered roller bearings have been mass-produced, and it has established a joint R&D mechanism with many domestic robot manufacturers. In 2024, the revenue of the robot business will increase by 80% year-on-year.

Breakthrough opportunities for non-listed bearing companies

1. Technology positioning in niche areas

Miniature bearings: The miniature cross roller bearings developed by YFB have a precision of P4 and are suitable for medical robot surgical instruments. The unit price of the product is 3 times that of traditional bearings. High-temperature bearings: The ceramic-based self-lubricating bearings of Luoyang Hongyuan Bearing have a lifespan of more than 10,000 hours in extreme environments of -200℃ to +300℃, and have been verified by Yihuatong hydrogen compressors. Smart bearings: Renben Group launched IoT bearings with integrated vibration and temperature sensors, which can achieve predictive maintenance of robot joints through AI algorithms, with a product premium rate of 40%.

2. The dividend release of supply chain collaboration

Car companies' cross-border cooperation: Xiaomi, NIO and other car companies' layout in the field of humanoid robots has driven the collaboration between bearing companies and the automotive supply chain. For example, C&U provides customized needle roller bearings for NIO Bot, which is 35% cheaper than imported solutions. Equipment manufacturers' linkage: The technological breakthroughs of domestic grinding machine manufacturers such as Yuhuan CNC and Qinchuan Machine Tool help small and medium-sized bearing companies break through the bottleneck of high-precision processing. In 2024, the market share of domestic high-end grinders will increase from 15% to 30%, driving the processing cost of micro bearings down by 20%.

3. Policy-driven domestic substitution window

Standard-making power competition: The "Humanoid Robot Bearing Performance Intercommunication Standard" promoted by the Ministry of Industry and Information Technology is being formulated. Guangyang Co., Ltd., XCC*ZXZ and other companies are leading the technical parameter setting. Non-listed companies can quickly enter the mainstream supply chain by participating in standard certification. Support for specialization, precision and innovation: In 2024, the central government will increase its R&D subsidies for "little giant" enterprises by 50%. Small and medium-sized enterprises focusing on robot bearings can receive up to 20 million yuan in funding support for material research and development and production line upgrades.

From the technical breakthroughs of listed companies to the segmented breakthroughs of unlisted companies, China's bearing industry is forming a three-dimensional competitive landscape of "high-end breakthrough, mid-end consolidation, and low-end optimization". As Tesla Optimus is approaching mass production (expected in Q4 2025), the demand for 70 bearings per robot will detonate a market worth hundreds of billions. Whether it is a leader that has landed in the capital market or a hidden champion that has deeply cultivated a segmented field, companies that master the three core technologies of high precision, long life, and intelligence will share the biggest dividends in this robot revolution.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Schaeffler honors outstanding suppliers

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.