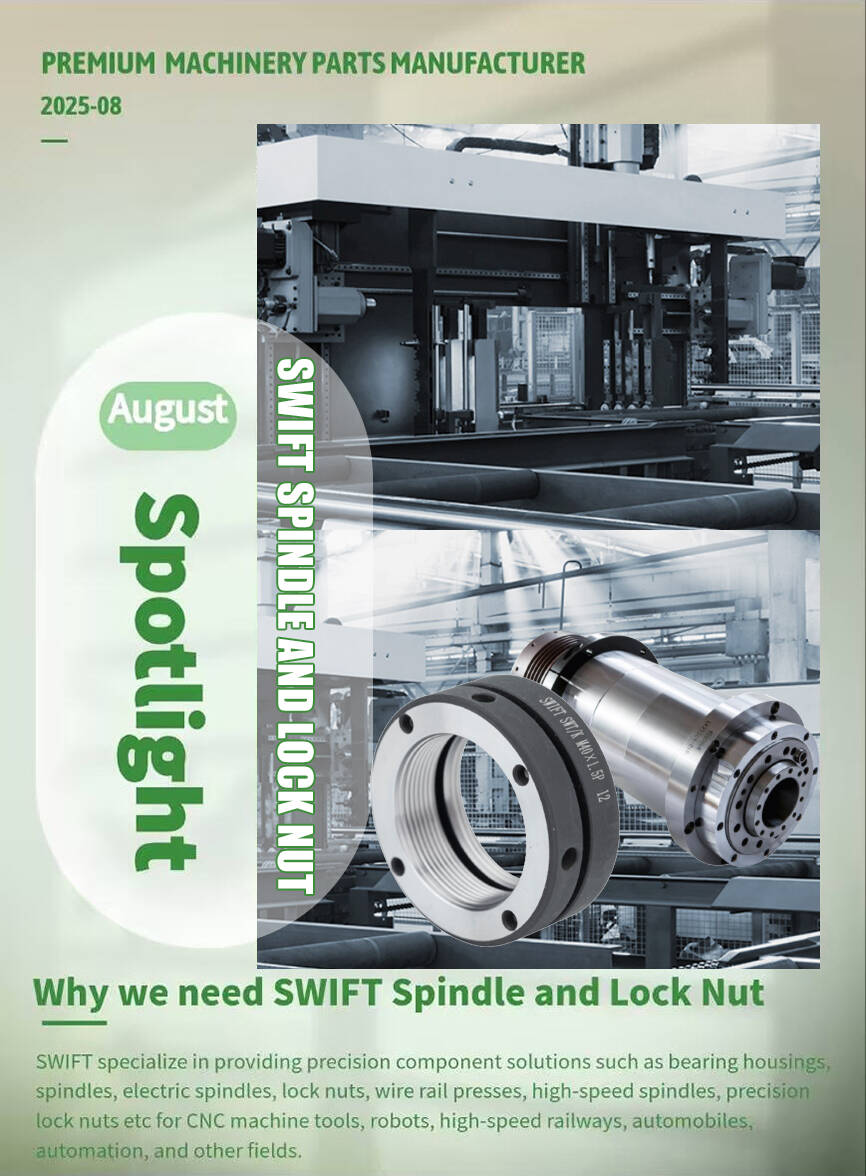

2025 August Spotlight: SWIFT Spindle and Precision Lock Nut

It is our great pleasure to present 2025 August excellent precision marchinery parts from a premium manufacturer member Jiangsu Swift Machinery Technology Co., Ltd

Why we need SWIFT Spindle and Lock Nut ?

Precision Component Solutions Provider,Spare no expense in the pursuit of perfection, down to the last

0.001.

Leveraging 12 years of extensive R&D capabilities in high-precision CNC accessory products, we integrate internationally advanced equipment with efficient flexible manufacturing capacity and strong customer collaboration. SWIFT offer over 40 different specifications of precision components, delivering optimal solutions for global leading manufacturing sectors.

Application

Machine tool

Industrial robot

High speed rail industry

Compressor industry

Gearbox industry

Injection moulding machine industry

Paper machine industry

Pumps and fans

Woodworking machinery

Precision Lock Nut

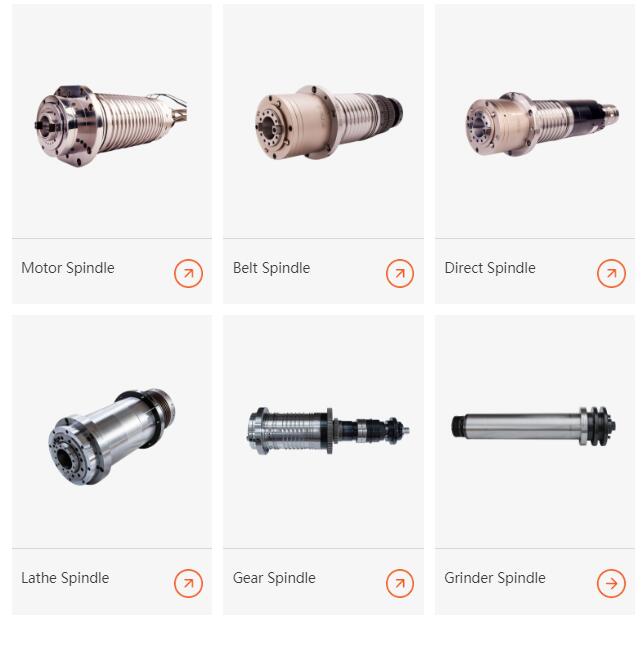

Spindle

SWIFT Technical Strength

Manufacturing Centre

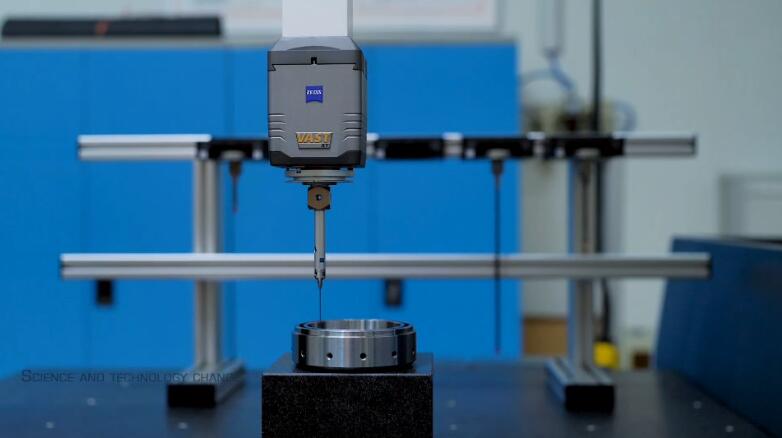

Modern constant-temperature precision processing and assembly workshop, the introduction of Swiss STUDER CNC precision universal grinder,Korea DOOSAN turning centre,machining centre, Germany ZEISS Coordinate, Germany Marr profiler and shape measuring instrument and other testing and experimenting equipments, in order to pursue more perfect products.

R&D Centre

Since entering the industry for 17 years,SWIFT have a wealth of high-precision CNC parts product research and development capabilities, and actively cooperate with major research institutes as well as leading companies in research and development.We provide new knowledge and better solutions for our customers and the component industry. So far, SWIFT have developed more than 40 kinds of precision components products with different specifications.

Inspection Centre

SWIFT has introduced advanced testing equipment such as German Zeiss CMM, German Mahr Profilometer and Shape Measuring Instrument. Adopting German SAP management system, SWIFT have set up a complete and strict inspection system, and are committed to the pursuit of better product quality.

For more info, please visit www.jsswft.com send email to tracy.ding@jsswft.com

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Nantong Vice Mayor Ling Yi convened a machine tool industry conference at Guosheng. SWIFT, as a core machine tool component manufacturer, participated in the conference.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.