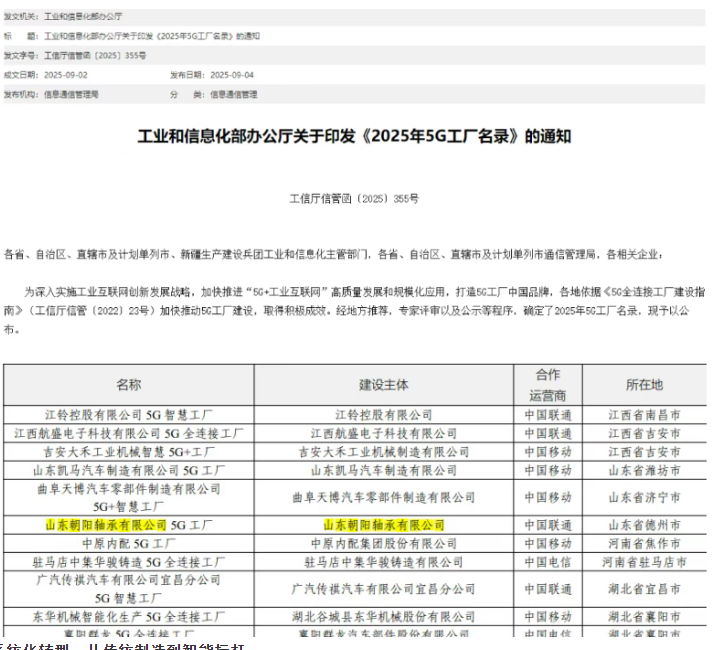

Shandong Chaoyang Bearing Enters China MIIT 2025 5G Factory List

The General Office of the Ministry of Industry and Information Technology recently released the "2025 5G Factory List," which includes 560 projects across 48 industries nationwide. Shandong Chaoyang Bearing Co., Ltd. made the list, becoming the only company in Dezhou City to be selected. This marks the company's achievement of national recognition in its "intelligent transformation and digital transformation" efforts.

Systematic Transformation: From Traditional Manufacturing to Intelligent Benchmark

Shandong Chaoyang Bearing has long focused on technological innovation and industrial upgrading, actively responding to the national strategy of "deep integration of the digital economy and the real economy" and integrating the concept of "digital intelligence empowerment" throughout its entire value chain.

With "intelligent transformation and digital transformation" as its core strategy, the company has systematically addressed bottlenecks in multiple areas, including production efficiency, safety control, energy management, and quality consistency, gradually building a comprehensive intelligent production system.

Relying on support from local industrial policies, the company invested in the construction of a 5G smart production workshop. By deploying a 5G enterprise private network, the company achieved low-latency, highly reliable interconnection between equipment, sensors, and control systems, increasing production cycle time by over 30% and shortening product delivery cycles by nearly 20%.

Breakthroughs in Technological Innovation Achieved in Multiple Fields

In terms of production safety and energy management, the company integrated the use of "5G + AI machine vision" and IoT monitoring technologies. High-definition smart cameras were deployed to identify equipment status and personnel behavior in real time, strengthening human safety protection.

The company also established an energy management system to implement refined management of key nodes such as electricity and gas consumption, reducing energy consumption per unit of product by over 15%, achieving both economic and environmental benefits.

In its quality management system, a 5G-based full-process traceability system enables data integration from raw materials to finished products, significantly improving product qualification rates and significantly enhancing customer satisfaction and market trust.

Outlook: A New Starting Point for Digitalization

For the company, being selected as a national-level 5G factory is merely a new starting point in its digitalization journey. Wan Xinhai, the company's head, stated that the company will continue to deepen the integration of 5G technology across all aspects of manufacturing, operations, and services, continuously optimize its intelligent production system, and actively share its transformation experience. This will allow the company to collaborate with upstream and downstream industries to achieve comprehensive upgrades, injecting new momentum into the high-quality development of the regional manufacturing industry through innovation-driven empowerment and development-driven development.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next ZheJiang FengLi Planned to increase 730 million yuan for intelligent manufacturing projects in the gear field

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.