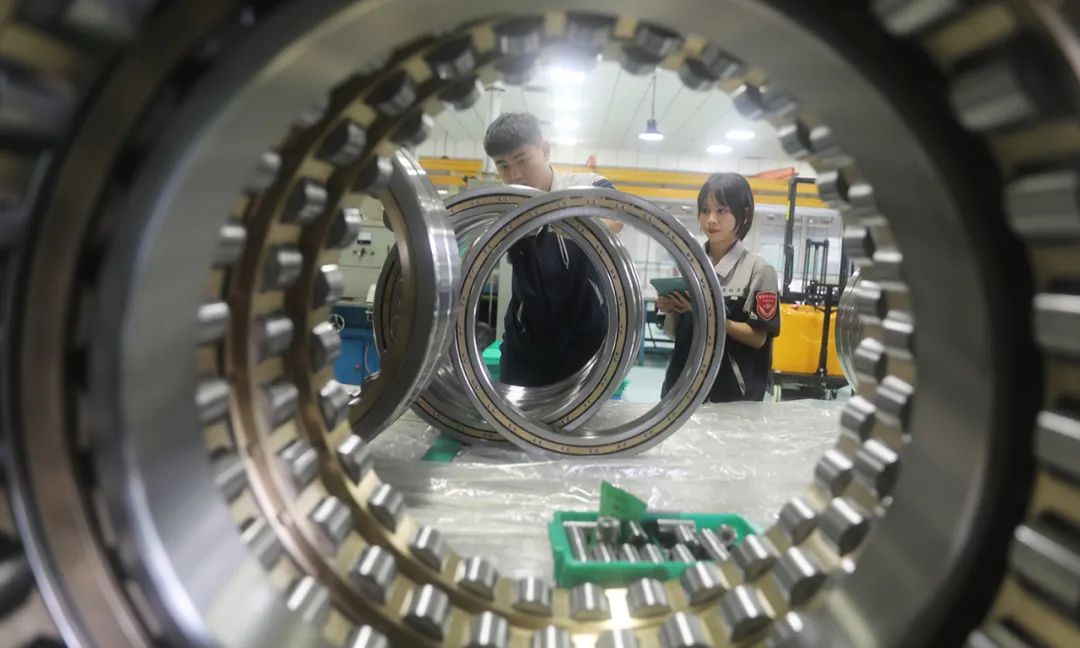

"This is not only a breakthrough, but also a product that fills the domestic gap. The maximum power of the wind turbine supporting the bearing has reached 12 MW." Cang Shiliang, director of the Wind Power Bearing Research Institute of the Wind Power Bearing Division of the ZWZ Group, proudly Say.

The wind turbine main shaft bearing is the core component of the wind turbine. It has the highest technical content in the wind turbine bearing and is known as the "heart" of the wind turbine. The localization rate of main shaft bearings of large megawatt wind turbines in China is not high.

There is no time to wait to promote self-reliance and self-improvement in technology, and only strive to break through the "stuck neck" problem. In production, ZWZ Group adheres to the innovation-driven development strategy, increases technological investment and R&D strength, and has made continuous breakthroughs in the design, R&D and production of wind turbine bearings. Following the completion of the installation of the large megawatt main shaft bearing, the 12 megawatt generator bearing has also been installed. Among them, the 7 MW spherical roller spindle bearing 240/1180 is currently the largest self-aligning spindle bearing used in the wind power industry.

In the process of research and development, the R&D team of ZWZ Group combined design technology, material technology and manufacturing technology to overcome the bottleneck of multi-process processing of product manufacturing and meet the overall use requirements and high bearing capacity requirements.

At the same time, in order to build an innovation platform for skilled workers, the trade union of ZWZ Group launched the construction work of "vigorous trade union", and took the lead in organizing and promoting the "Decisive Battle 8 Billion, Gifts to the 20th National Congress" meritorious competition activities, focusing on breakthroughs in production capacity, technological breakthroughs, process innovation, equipment In terms of failure reduction and efficiency improvement, organize grass-roots units to carry out new record-setting activities; focus on improving efficiency and management level, and carry out championship ranking activities around market development, order supply guarantee, quality improvement, production capacity stability, cost reduction and efficiency improvement, etc. ; Carry out technical competitions in key job types such as CNC grinders, CNC lathes, and bearing manufacturers. A series of measures have accelerated the implementation, flowering and results of innovative projects for front-line skilled workers.

"Take the 7 MW spherical roller spindle bearing 240/1180 as an example, it took us less than 4 months from the design and development to the completion of production, and other models can be even faster. Moreover, the above-mentioned bearings are filled with It has eliminated the domestic blank and reached the advanced level of the international industry." Cang Shiliang said.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.