Working Modes

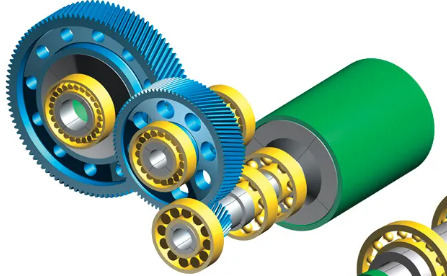

The KISSsoft System Module links all gearbox components for simultaneous strength and lifetime analysis, with 3D visualization that accelerates concept development, balances designs early and simplifies documentation in a single integrated file.

The System Module combines kinematic analysis, lifetime calculation, 3D graphics and system reports with a programming language. It is the tool of choice for strength and lifetime analysis of various kinds of geared systems and gearboxes. The System Module lets the user do quick and detailed parametric studies of a complete power train in very little time to compare different variants of a concept or to analyze a given design for different loads.

In the System Module, all parts (gears, shafts, bearings, connections) of the gearbox are linked and the strength / lifetime analysis is performed simultaneously for all elements. A three-dimensional graphical presentation of the current state of the system immediately shows the geometrical influence of every change in parameters. This approach greatly accelerates the design process and results in a much more balanced design even during the concept phase.

With system-level kinematic analysis at its core, the KISSsoft System Module supports a wide range of drivetrain configurations—from planetary systems to CVTs—enabling accurate, efficient modeling of speed, torque, and power across complex transmission architectures.

The machine elements calculated range from gears, shafts, bearings to shaft-hub connections. This will result in a more balanced starting design and fewer modifications will be necessary further down in the design process to reach an optimized design. Furthermore, documentation of the calculation is simplified and all calculation data for the whole gearbox is stored in a single file. The System Module uses other KISSsoft modules for the strength and lifetime calculations of the various components used in the system.

Basis of all component calculations is the system level kinematics calculation covering:

Speed, torque, and power for complex systems including gears, couplings, speed and torque limiter, multiple boundary conditions

Modeling of planetary systems like Ravigneaux, Wolfrom, Wilson, Simpson

Differentials, (with bevel, face or spur gears), chain and belt transmissions

Couplings may be activated and deactivated, slippage considered

Allows for modelling of CVT transmissions

System ratio and mesh ratio table in Kinematics tab

Switching matrix for defining gear speeds

Definition of operating modes, combining different boundary conditions with load spectra.

With KISSsoft, the user may choose between three working modes:

Component Level Only: This mode involves using KISSsoft modules other than the System Module. It’s a detailed, low-cost, and time-saving approach suitable for less complex systems where calculations for individual components are done independently from each other. This mode is ideal for projects requiring maximum speed, efficiency, and simplicity.

System Level: This mode integrates components into a holistic system, combining power flow analysis, spatial and collision-free arrangement, and top-level requirements-driven conceptual design. It is highly efficient for experienced designers with a deep understanding of all aspects of gearbox or transmission design. It is the mode of choice for most licensees globally.

Collaborative Approach: The System Module supports a team-based design process. Domain experts work on individual components using independent KISSsoft instances, performing detailed sizing, optimization, and analysis. Iterative design improvements are uploaded into the system model, enhancing its fidelity step-by-step.

Switching between these modes is immediate, with data exchange enabled through KISSsoft files as well as bespoke and neutral formats (e.g., Gleason GAMA, Gleason GEMS, GDE and REXS).

The KISSsoft System Module supports three flexible working modes—Component Level, System Level, and Collaborative—enabling seamless transitions between independent, integrated, and team-based design approaches for maximum efficiency and adaptability.

Return on Investment

The System Module’s parameter-based design approach manages the numerous parameters of gearbox and bearing design efficiently, reducing errors from manual data transfer. Experience from hundreds of projects confirms that the module accelerates project timelines and reduces errors, even for basic designs. Once engineers become proficient, they consistently rely on the System Module for its efficiency and accuracy.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.