The prototype of the 56” Class 900 high-pressure large-diameter fully welded ball valve for long-distance natural gas pipelines passed the appraisal

On October 24-25, the China Machinery Industry Federation and the China General Machinery Industry Association held a product prototype appraisal meeting in Beijing for the 56” Class 900 high-pressure large-diameter fully welded ball valve for long-distance natural gas pipelines (model: A560Hdz967F-900-DIB 1) jointly developed by Beijing Valve General Factory Co., Ltd. and Zhonghong Valve Co., Ltd. The appraisal meeting was hosted by Huang Li, President of the China General Machinery Industry Association.

Sui Yongbin, former chief engineer of the China Machinery Industry Federation, serves as the leader of the expert group of the appraisal committee. The expert group is composed of experts from the China Machinery Industry Federation, the Petroleum Science Popularization Education Committee of the China Petroleum Society, Hefei General Machinery Research Institute Co., Ltd., the Petroleum Storage and Transportation Professional Committee of the China Petroleum Society, China Petroleum and Natural Gas Pipeline Engineering Co., Ltd. Shanghai Branch, Lanzhou University of Technology, National Pipeline Network Group West-East Gas Pipeline Branch, National Pipeline Network Group Western Pipeline Co., Ltd., National Pipeline Network Group Engineering Quality Supervision and Inspection Co., Ltd. and other units.

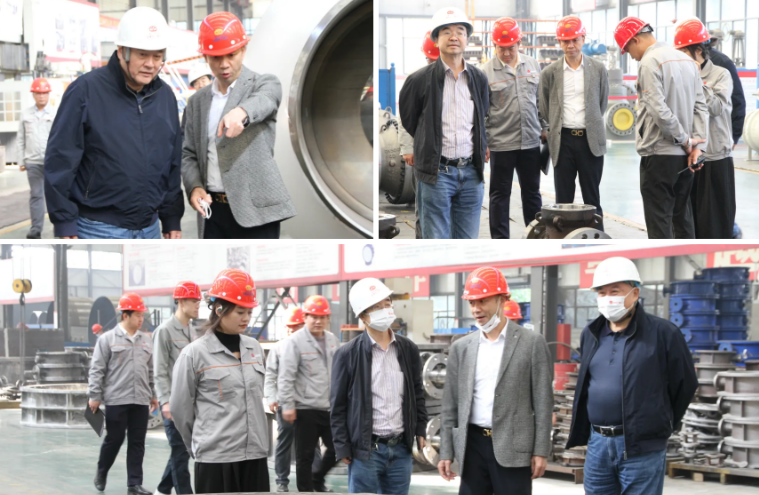

The experts at the meeting listened to the technical requirements and summary report of the development, and consulted the relevant technical documents. Before the meeting, the expert representatives visited the production test site and witnessed some factory tests of the products. The main innovations and technical features of the jointly developed 56” Class 900 high-pressure large-diameter full-connection ball valve for long-distance natural gas pipelines are: the use of advanced design calculation and strength stress assessment methods ensures the reliability of the valve structure under various loads; the shell adopts a conical cylindrical fully welded valve body + valve ball support plate structure, which realizes a compact design under large-diameter and high-pressure conditions; the main welds of the left and right bodies and the middle body of the valve have passed the -46℃ fracture toughness test and the ECA assessment without post-weld heat treatment, and the TOFD detection of welding defects and ultrasonic detection of weld residual stress have improved the safety and reliability of the welds; the valve seat adopts a quadruple sealing structure, and the valve stem adopts multiple sealing and anti-flying structures to improve the sealing and safety of the valve.

The appraisal committee believes that the developed 56” Class 900 high-pressure large-diameter fully welded ball valve has independent intellectual property rights, and its main performance indicators have reached the advanced level of similar international products. After passing the industrial test, it can be promoted and applied on long-distance natural gas pipelines.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Guomao reducer helps the port's first crawler bucket wheel loader to be officially put into use

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.