Intelligently Manufactured Automatic Grab Crane by Henan Mine Goes into Operation

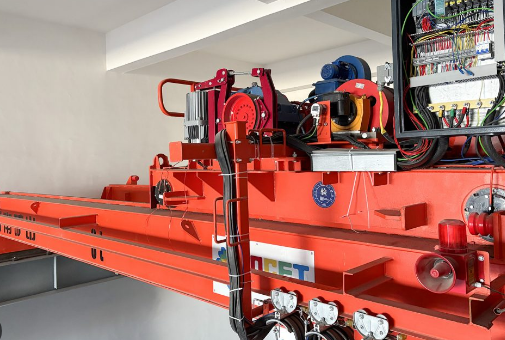

Recently, an automated grab crane developed and manufactured by Henan Mining for a waste-to-energy incineration project was officially put into operation. Its features, including automatic fixed-point grabbing and constant-weight cyclic operation, have garnered significant attention, making it another innovative product from the "Mining Resources" intelligent manufacturing initiative.

This "miracle machine" boasts several technological advantages: It is equipped with a variable frequency speed control system, coupled with an absolute encoder to achieve millimeter-level position control. It integrates anti-sway, automatic fixed-point grabbing, and constant-weight cyclic operation into a single unit, creating a fully automated closed-loop operation.

Triple Control + Expansion Interface: Adapting to Diverse Scenarios

It adopts a triple control mode of "manual + wireless remote control + fixed-point unloading," balancing intelligent convenience with flexible adjustment. A fully automatic interface is reserved, allowing seamless integration with subsequent capacity upgrades and process adjustments, providing ample space for intelligent iteration of the production line.

Nine Protection Measures + Precise Speed Control: Building a Solid Safety Line

Equipped with nine protection functions including short circuit, overload, and lifting limit, and combined with PLC + frequency conversion speed control technology, it achieves smooth start-up and shutdown and precise speed control. This effectively reduces mechanical wear and avoids safety hazards at the source, ensuring stable equipment operation.

Benchmark Cases Showcase Henan Mining's Core Strength

The successful commissioning of this automatic grab crane is just one example among many benchmark cases at Henan Mining. In multiple sub-sectors such as aluminum processing and waste treatment, Henan Mining continues to break through technological bottlenecks, providing customized intelligent equipment and full life-cycle services, winning widespread customer recognition.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Rollout of MCC Shaan-Ya Self-Designed 1750mm Meifugan Cold Roller Leveler

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.